1. Introduction

Electric tile cutters are essential tools for both professional contractors and DIY enthusiasts who seek precision and efficiency in their tile cutting work. Unlike manual tile cutters, these powered devices allow for quick, clean cuts with minimal effort and are particularly effective for handling large volumes of tiles or materials that are hard to cut manually.

1.1 Overview of Electric Tile Cutters

Electric tile cutters come equipped with diamond-tipped blades and use electricity to spin the blade, which cuts through ceramic, porcelain, and stone tiles. They are available in various designs, including tabletop versions for large projects and handheld models for intricate work. Brands like DeWALT DWC860W and Bosch Tools TC10 are popular for their robustness and precision.

1.2 Benefits of Using Electric Tile Cutters

Precision and Consistency: Electric tile cutters ensure precise cuts, reducing tile wastage and ensuring that each piece fits perfectly as planned in the layout.

Versatility: With the ability to adjust blade heights and angles, electric tile cutters can perform straight, L-shaped, and beveled cuts, accommodating different project needs.

Efficiency: These tools significantly speed up the tile cutting process, making them ideal for projects requiring numerous or complex cuts.

Ease of Use: Electric tile cutters require less physical effort compared to manual cutters, making them more accessible to individuals of all skill levels.

Safety Features: Most models come with built-in safety features, such as water spray systems that keep the blade cool and reduce dust, enhancing the cutting experience and prolonging the life of the blade.

These benefits make electric tile cutters a valuable tool for achieving professional-quality results in tiling projects, whether in home renovations or commercial settings.

2. Types of Electric Tile Cutters

Electric tile cutters are categorized based on their cutting mechanisms and the environments they are best suited for. Each type offers unique benefits and has certain limitations, making them suitable for different tiling tasks.

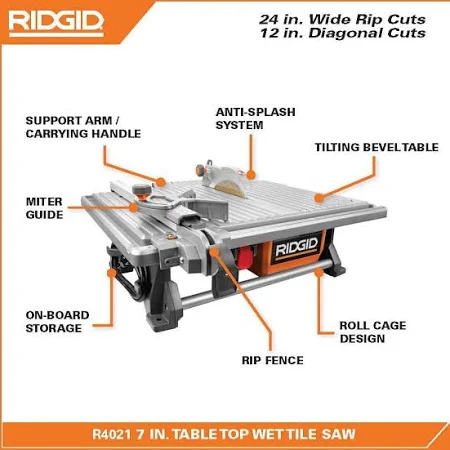

2.1 Wet Tile Cutters

Wet tile cutters use water to cool the cutting blade, which reduces dust and heat, preventing the blade from overheating and prolonging its life. A common example is the MK Diamond MK-370EXP, known for its powerful high-torque motor.

Pros:

- Dust Reduction: Water spray controls dust for a cleaner work environment.

- Cooling Feature: Extends the blade’s life and prevents overheating.

- Precision Cuts: Ideal for cutting dense materials like porcelain and stone.

Cons:

- Setup Time: Requires setup for water source and drainage.

- Maintenance: Regular cleaning to prevent sludge buildup.

- Limited Portability: Generally heavier and less portable than dry cutters.

Specifications Table:

| Feature | MK Diamond MK-370EXP |

|---|---|

| Power | 1-1/4 HP motor |

| Blade Diameter | 7 inches |

| Cutting Depth | 2 inches |

| Weight | 33 pounds |

| Price Range | $350 – $450 |

2.2 Dry Tile Cutters

Dry tile cutters, such as the Rubi Tools DC-250 1200, are designed for jobs where water use is impractical. They are lightweight and easily portable but generate more dust compared to wet cutters.

Pros:

- Portability: Easy to transport and set up at various job sites.

- Convenience: No need for water, simplifying the cutting process.

- Immediate Use: Ready to use with minimal setup.

Cons:

- Dust Production: Generates a lot of dust, requiring good ventilation or a dust extraction system.

- Blade Wear: Faster wear on the cutting blade due to no water cooling.

- Noise: Generally louder than wet tile cutters.

Specifications Table:

| Feature | Rubi Tools DC-250 1200 |

|---|---|

| Power | 1.5 HP motor |

| Blade Diameter | 10 inches |

| Cutting Length | 47.2 inches |

| Weight | 121 pounds |

| Price Range | $1,100 – $1,300 |

2.3 Handheld Electric Tile Cutters

Handheld electric tile cutters, like the DeWALT D24000, offer flexibility for making quick cuts and adjustments on the fly. They are ideal for cutting tiles already installed or for making small cutouts.

Pros:

- Flexibility: Allows for cutting tiles in place or on an installed surface.

- Compact Design: Easy to handle and maneuver in tight spaces.

- Quick Setup: Minimal setup required, enhancing workflow efficiency.

Cons:

- Limited Cutting Capacity: Not suitable for long or straight cuts.

- Manual Operation: Requires steady hands for precision, which can vary by user.

- Durability: Less robust than tabletop models.

Specifications Table:

| Feature | DeWALT D24000 |

|---|---|

| Power | 1.5 HP motor |

| Blade Diameter | 4.5 inches |

| Maximum Cut Depth | 1.375 inches |

| Weight | 69 pounds |

| Price Range | $800 – $950 |

Each type of electric tile cutter offers specific advantages depending on the project requirements, whether it’s for large-scale industrial use or for detailed, intricate cutting tasks in smaller or more delicate installations.

Top deals

3. Key Features to Consider Before Buying

When shopping for electric tile cutters, several specific features can significantly impact their performance and suitability for particular tasks. Understanding these can help you select the most appropriate model for your needs.

3.1 Cutting Power and Speed

The power and speed of an electric tile cutter determine its ability to handle different materials and the efficiency with which it operates. For example, the Bosch TC10 offers a powerful 1.4 HP motor that delivers 4200 RPM, making it suitable for cutting tough materials like granite and porcelain quickly and cleanly.

Considerations:

- Motor Horsepower: More horsepower means the cutter can handle tougher materials.

- Rotational Speed (RPM): Higher RPM speeds allow for faster cutting but may require more skill to manage.

3.2 Blade Types and Adjustability

The type of blade and its adjustability are crucial for making precise cuts on various tile materials. The MK Diamond MK-370EXP features a diamond blade that can tilt and adjust for making 22.5° and 45° bevel cuts, providing flexibility for complex tiling projects.

Considerations:

- Blade Material: Diamond blades are preferred for their durability and precision.

- Adjustability: Look for models that offer easy adjustments to handle bevel cuts and complex shapes.

3.3 Size and Portability

Depending on your workspace and the projects you tackle, the size and portability of your tile cutter are important. The Rubi Tools DC-250 1200 is notable for its large cutting length of 47.2 inches, ideal for large tiles, but it weighs 121 pounds, which impacts its portability.

Considerations:

- Weight: Lighter models are easier to move but might offer less stability than heavier ones.

- Footprint: Consider the physical space the cutter will occupy, especially if your workspace is limited.

3.4 Additional Features

Additional features such as water systems and guide rails enhance the functionality and safety of electric tile cutters. The DeWALT D24000 stands out with its integrated water system that significantly minimizes dust and cools the blade, extending its lifespan. It also features an adjustable dual water nozzle allowing for optimal water placement on the blade.

Considerations:

- Water System: Essential for wet cutting, it keeps the blade cool and reduces dust.

- Guide Rails: They ensure straight, accurate cuts, crucial for achieving professional results.

By considering these key features and how they align with your project needs, you can make a well-informed decision when purchasing an electric tile cutter, ensuring you get a tool that not only meets but exceeds your expectations.

4. Best Practices for Using Electric Tile Cutters

To maximize the performance and lifespan of your electric tile cutter, follow these best practices tailored for efficient and safe use.

4.1 Setting Up Your Workspace

Preparing your workspace correctly is crucial for efficient operation and safety when using tile cutters like the Bosch TC10.

Tips:

- Stable Surface: Ensure your cutter is set up on a stable, level surface to prevent any movement during operation. For large models such as the Rubi Tools DC-250 1200, reinforce stability with a solid stand or workbench.

- Water Supply and Drainage: For wet tile cutters, arrange a consistent water supply and proper drainage system. This setup is crucial to keep your work area clean and safe, preventing water buildup.

- Accessibility: Position your tile cutter so that you have easy access from all sides. For larger units, ensure you have enough space to maneuver large tiles comfortably.

4.2 Safety Precautions

Electric tile cutters, while efficient, pose risks if not handled correctly. Proper safety measures are imperative.

Tips:

- Personal Protective Equipment (PPE): Always wear safety goggles, ear protection, and gloves. The DeWALT D24000 operates at high speeds, making eye and ear protection essential.

- Check the Equipment: Before use, inspect the tile cutter for any damage or defects. Check the integrity of the blade and ensure all safety guards, like those on the MK Diamond MK-370EXP, are in place.

- Clear Area: Keep the area free of clutter and ensure all cables are secured to avoid tripping hazards.

4.3 Maintenance Tips

Regular maintenance ensures your tile cutter operates effectively and extends its lifespan.

Tips:

- Blade Inspection and Replacement: Check the blade regularly for wear and replace it when necessary. Diamond blades, like those used in the Bosch TC10, require checking for any cracks or excessive wear.

- Cleaning: After each use, clean the machine thoroughly. Remove tile residues and sludge, especially from models with a water system like the DeWALT D24000. This prevents buildup and potential corrosion.

- Storage: Store the tile cutter in a dry, clean environment. For portable models like the Rubi Tools DC-250 1200, use a protective cover to shield them from dust when not in use.

Following these specific practices will help you achieve optimal results with your electric tile cutter and maintain its condition for future projects.

5. Top Electric Tile Cutters on the Market

To help you make an informed decision, here’s a breakdown of three top-rated electric tile cutters currently available on the market. Each model has been selected based on its features, usability, and customer feedback.

5.1 Model 1: DeWALT D24000 Wet Tile Saw

5.1.1 Features

- Motor: 1.5 HP which allows for cutting hard materials like porcelain and stone.

- Blade Size: 10-inch diamond blade for precision cuts.

- Cutting Capacity: Rip cut capacity of 24 inches, and diagonal cut capacity of 18 inches.

- Water Pan: Integrated 5-gallon water pan with dual water nozzles for optimal blade cooling.

5.1.2 Pros and Cons

Pros:

- High power motor suitable for various materials.

- Large cutting capacity ideal for bigger projects.

- Portable design with a frame that allows for easy setup and transportation.

Cons:

- Higher price point.

- Requires space for operation due to its size.

5.1.3 Price Range

- $850 – $950

5.2 Model 2: Bosch TC10 Wet Tile and Stone Saw

5.2.1 Features

- Motor: 1.4 HP, providing ample power for most tile and stone jobs.

- Blade Size: 10-inch premium diamond blade.

- Cutting Capacity: Can perform 24-inch rip cuts and 18-inch diagonal cuts.

- Design: Features a large work surface and robust design for handling large tiles.

5.2.2 Pros and Cons

Pros:

- Sturdy construction enhances durability.

- Extensive cutting capacity suitable for various tile sizes.

- Precision cutting with minimal vibration.

Cons:

- Quite heavy, impacting portability.

- More expensive due to high-end construction.

5.2.3 Price Range

- $1,100 – $1,200

5.3 Model 3: MK Diamond MK-370EXP Tile Saw

5.3.1 Features

- Motor: 1.25 HP which balances power and efficiency.

- Blade Size: 7-inch diamond blade, perfect for detailed and intricate cuts.

- Cutting Capacity: 18-inch length and 13-inch diagonal cuts.

- Unique Feature: Hinged blade guard for easy blade changes.

5.3.2 Pros and Cons

Pros:

- Lightweight design improves portability.

- Simple to change blades and maintain.

- Affordable price suitable for hobbyists and professionals alike.

Cons:

- Less suitable for very heavy-duty cutting.

- Smaller blade size limits the cutting of larger tiles.

5.3.3 Price Range

- $420 – $480

Comparison Table for All Models

| Model | Motor Power | Blade Size | Max Rip Cut | Price Range | Notable Features |

|---|---|---|---|---|---|

| DeWALT D24000 Wet Tile Saw | 1.5 HP | 10-inch | 24 inches | $850 – $950 | Dual water nozzles, large water pan, high portability |

| Bosch TC10 | 1.4 HP | 10-inch | 24 inches | $1,100 – $1,200 | Robust design, extensive cutting capacity |

| MK Diamond MK-370EXP | 1.25 HP | 7-inch | 18 inches | $420 – $480 | Lightweight, easy blade changes |

This comparison provides a clear snapshot of what each model offers, helping you decide based on your specific needs and budget constraints.

How to Use an Electric Tile Cutter

Using an electric tile cutter can significantly simplify your tile cutting work, providing precision and efficiency. Follow this step-by-step guide to ensure you get the best results:

Step-by-Step Guide

Prepare Your Workspace:

- Ensure the area is clean and free of obstructions.

- Set up your tile cutter on a stable, level surface.

Measure and Mark Your Tiles:

- Use a pencil and a square or a measuring tape to mark where you need to cut the tile.

- Double-check measurements to ensure accuracy.

Set Up the Electric Tile Cutter:

- Install the appropriate blade for the type of tile you are cutting.

- Fill the water reservoir if using a wet cutter to keep the blade cool and minimize dust.

Adjust the Guide Fence:

- Align the guide fence to your marked line for precision cutting.

- Ensure the fence is securely locked in place.

Cut the Tile:

- Turn on the machine and let the blade reach full speed.

- Gently push the tile towards the blade, applying steady pressure.

- Keep your hands away from the moving blade at all times.

Inspect and Smooth the Edge:

- Turn off the machine and inspect your cut.

- Use a sanding stone or a rubbing stone to smooth any rough edges.

Safety Precautions

Wear Protective Gear:

- Always wear safety goggles to protect your eyes from flying debris.

- Use ear protection to guard against prolonged noise exposure.

- Consider wearing a dust mask, especially when cutting dry.

Check Equipment Before Use:

- Inspect the tile cutter for any damage or loose parts before starting your project.

- Ensure the blade is sharp and securely attached.

Operate with Care:

- Keep your hands clear of the blade at all times.

- Do not attempt to cut tiles that are too small to be safely supported.

Maintain a Clean Work Area:

- Regularly clear away tile debris to prevent slips and trips.

Maintenance Tips

Regular Cleaning:

- Clean the machine after each use, focusing on removing tile residue from the blade and cutting table.

- Drain and clean the water reservoir of a wet cutter to prevent sludge build-up.

Blade Care:

- Check the cutting blade regularly for wear and tear.

- Replace the blade as needed to ensure clean, precise cuts.

Machine Storage:

- Store the tile cutter in a dry, dust-free environment to prevent rust and corrosion.

- Cover the machine to protect it from dust when not in use.

Scheduled Inspections:

- Periodically check all moving parts and electrical components for signs of wear or damage.

- Consult the manufacturer’s manual for specific maintenance routines and adhere to recommended schedules.

Common Mistakes to Avoid

When using an electric tile cutter, certain mistakes can not only compromise the quality of your tile cuts but also pose safety risks. Here are some of the most common errors you should avoid:

Incorrect Blade Selection

Choosing the right blade for the material you are cutting is crucial for both the quality of the cut and the longevity of your blade.

- Material Mismatch:

- Always select a blade designed specifically for the type of tile you are cutting. For example, porcelain tiles require a different blade than ceramic tiles.

- Blade Condition:

- Using a worn-out or damaged blade can result in chipped or uneven cuts. Inspect your blades regularly and replace them when necessary.

- Cutting Speed:

- Using a blade at incorrect speeds can lead to poor performance. Make sure the blade’s maximum speed matches or exceeds the speed of the cutter.

Improper Cutter Setup

Setting up your tile cutter correctly is fundamental to achieving precise cuts. An improper setup can lead to inaccurate cuts and potential hazards.

- Guide Fence Alignment:

- Ensure the guide fence is parallel to the blade for straight cuts. Misalignment can cause the tile to crack or break.

- Secure Attachments:

- All components, especially the blade and guide fence, must be securely attached before use. Loose components can lead to inaccurate cuts and are a major safety hazard.

- Water Reservoir (for wet cutters):

- Check that the water reservoir is filled to the appropriate level to keep the blade cool and reduce dust. Neglecting this step can cause overheating and blade damage.

Overloading the Machine

Pushing your tile cutter beyond its limits can significantly reduce its lifespan and increase the risk of malfunction.

- Feed Rate:

- Pushing the tile through the cutter too quickly can overload the machine and result in poor cuts. Feed the tile slowly and steadily.

- Thickness and Size:

- Do not attempt to cut tiles that are thicker or larger than what the cutter is designed to handle. Check the maximum cutting thickness and size specifications in the user manual.

- Continuous Operation:

- Avoid running your electric tile cutter for extended periods without breaks. Overheating can damage the motor and the blade.

FAQs

Are electric tile cutters better than manual?

Electric tile cutters are generally considered better than manual tile cutters for several reasons. They offer more precision, especially for complex cuts like angles and curves, and they require less physical effort, making them ideal for large projects or dense materials like porcelain or stone. For example, the DeWalt D24000S Wet Tile Saw provides high accuracy and can handle bulk cutting tasks that would be strenuous with a manual cutter.

What is the best method to cut tile?

The best method to cut tile depends on the type of tile and the cut’s complexity. For straight cuts on ceramic tiles, a manual score-and-snap cutter is sufficient and cost-effective. However, for intricate cuts on harder materials like porcelain or natural stone, an electric wet tile saw like the Bosch TC10 Wet Tile Saw is recommended due to its precision and ability to reduce dust and heat with water.

What is an electric tile cutter?

An electric tile cutter, often referred to as a tile saw, is a power tool equipped with a diamond-coated blade that uses electricity to make cuts through tiles. It typically incorporates water (in wet cutters) to cool the blade and reduce dust. This tool is essential for projects that require frequent or complex cuts, such as tiling showers or backsplashes.

How much electricity does a tile cutter use?

The electricity usage of a tile cutter can vary depending on its motor size and efficiency. Generally, a standard electric tile cutter, like the Rubi DC-250 1200, which has a 1.1 kW motor, can consume about 0.9 to 1.1 kilowatt-hours (kWh) per hour of operation.

Is it better to cut tile wet or dry?

Cutting tile wet is generally better than dry because it reduces dust and extends the blade’s life by keeping it cool. Wet cutting, using tools like the MK Diamond MK-370EXP Wet Cutting Tile Saw, is ideal for materials that generate a lot of dust or are prone to overheating and cracking. Dry cutting is practical for quick, small jobs or where water use is impractical.

How thick of a tile can a tile cutter cut?

The maximum thickness a tile cutter can handle depends on the model. Standard electric tile cutters can typically handle tiles up to about 1.5 inches thick. Heavy-duty models, such as the Husqvarna TS 90 Tile Saw, can cut tiles up to 2.5 inches thick, accommodating thicker materials like pavers or stone tiles.

What are the hardest tiles to cut?

The hardest tiles to cut are porcelain and vitrified tiles due to their density and the method used in their production. These tiles require a diamond blade and often a water feed to cut properly, which is why electric tile cutters are generally necessary for these materials.

How do I choose a tile cutter?

Choosing a tile cutter depends on the type of tiles you will be cutting and the project size. Consider the following:

- Tile Type: Dense materials like porcelain need a powerful electric cutter with a diamond blade.

- Cutting Capacity: Make sure the blade and table size accommodate the tile sizes you intend to use.

- Features: Look for features like adjustable cutting guides, plunge cut capability, and continuous rim diamond blades. The Vitrex 103402NDE Diamond Blade Tile Cutter is an excellent example with a versatile set of features.

How to cut tiles without chipping?

To cut tiles without chipping:

- Use a continuous rim diamond blade, which is designed for chip-free cuts.

- Ensure your tile saw blade is sharp and not worn out.

- Feed the tile slowly and steadily into the saw.

- Use a wet saw to keep the cut edge cool and minimize flaking, such as the MK Diamond MK-101.

Why do tile cutters use water?

Tile cutters use water primarily to cool the diamond blade, which prevents overheating and reduces wear. Water also minimizes dust creation during cutting, which is essential for maintaining clean air quality and visibility while cutting.

Do you push or pull a tile cutter?

With manual tile cutters, you score the tile by pushing the scoring wheel across its surface. However, with electric tile cutters, you generally push the tile gently through the stationary blade, although some overhead models may require pulling the blade towards you.

What is electric tiles?

The term “electric tiles” might be a confusion. There is no specific category known as electric tiles in tiling. It is likely a misunderstanding or miscommunication. If you’re referring to heating systems under tiles, these are called “electric floor heating systems,” not electric tiles.