Tackling a tile installation project can be daunting, but choosing the right tools can make all the difference. Among the essential tools for cutting tiles, the wet saw tile cutter stands out for its precision and versatility. This guide delves into the capabilities of wet saw tile cutters, helping both DIY enthusiasts and professional builders understand why a wet saw is often the superior choice over traditional tile cutters.

Brief Overview of Wet Saw Tile Cutters

A wet saw tile cutter is designed specifically for handling a variety of tile materials, including ceramic, porcelain, and stone. Unlike dry cutters, a wet saw uses a water-cooled diamond blade to make clean and precise cuts. This cooling feature minimizes dust and extends the blade’s lifespan, making it a staple in tile cutting. Models like the Ryobi Wet Saw Tile Cutter offer a robust setup that suits both home renovations and larger commercial projects.

Importance of Using a Wet Saw for Tile Cutting

The decision between a tile cutter versus a wet saw boils down to the project’s specific needs. For intricate cutting tasks, such as fitting tiles around corners or cutting small tiles, the wet saw tile cutter proves indispensable. Its ability to deliver not just straight cuts, but also notches, beveled edges, and complex shapes, provides unmatched flexibility. For those considering tile cutting options, the wet saw vs. tile cutter debate often ends with the wet saw, particularly for projects requiring high precision and multiple cut types.

The Advantages of Wet Saw Tile Cutters

Precision Cutting: Wet saws are equipped with diamond blades that offer unparalleled accuracy. The Ryobi wet saw tile cutter, for example, allows for adjustments to be made down to the millimeter, ensuring that each tile fits perfectly in its designated space.

Reduced Dust and Debris: Since the cutting blade is continuously cooled by water, there is significantly less dust and debris, which not only makes for a cleaner work environment but also reduces the health hazards associated with dry cutting.

Versatility: Whether you’re cutting porcelain tiles for a bathroom renovation or slicing through thick marble for a kitchen backsplash, wet saw tile cutters like the workforce wet saw tile cutter are up to the task. Their robust design accommodates a wide range of tile types.

Rental Availability: Not ready to purchase? Wet saw tile cutter rental options are widely available at home improvement stores, making this tool accessible for one-time projects or occasional use.

2. How Wet Saw Tile Cutters Work

Understanding the mechanics and benefits of a wet saw tile cutter will help users effectively harness its capabilities for various tiling projects. This section explores how these tools function and why the integration of water is so crucial during the cutting process.

Basic Mechanics of a Wet Saw

A wet saw tile cutter operates quite differently from a standard tile cutter. At the heart of this tool is a diamond blade, which is specifically designed for cutting through hard materials like tile and stone. Unlike traditional blades, a diamond blade does not cut through abrasion. Instead, it grinds through the tile using the hard, sharp edges of the diamonds embedded around its edge.

Motor: The motor spins the diamond blade at high speeds, similar to a circular saw. In models like the Ryobi Wet Saw Tile Cutter and Workforce Wet Saw Tile Cutter, the motor is powerful enough to ensure smooth and steady cuts through even the most robust materials.

Water System: Integral to the wet saw is its water system, which pumps water directly onto the blade and tile. This system is crucial for both cooling and lubricating the blade, reducing friction, and preventing overheating.

Cutting Surface: Most wet saw tile cutters feature an adjustable cutting surface, allowing for precise control over the size and angle of the cut. This feature is particularly important for projects requiring multiple and varied cut types.

Benefits of Water in the Cutting Process

The inclusion of water in the cutting process of a wet saw tile cutter is not merely a convenience—it’s a significant enhancement that improves both the quality of the cut and the durability of the blade.

Cooling Effect: The water significantly cools the diamond blade during operation. This cooling is essential as it prevents overheating, which can warp the blade and negatively affect its cutting efficiency. The best wet saw tile cutter models utilize an optimized water system to ensure consistent blade temperature.

Dust Reduction: Water plays a crucial role in suppressing dust creation. By applying water directly to the cutting area, the wet saw keeps dust from spreading into the air, which not only creates a cleaner work environment but also reduces the health risks associated with inhaling silica dust.

Enhanced Precision: Wet saws offer superior precision in cuts. The water helps to keep the cutting line clear by washing away debris as the blade makes its pass. This visibility is crucial when making intricate cuts as required in detailed tiling projects.

Blade Longevity: The lubrication provided by the water reduces wear on the diamond blade, allowing for a longer lifespan than dry cutting blades. The diamond blade wet saw tile cutter models, therefore, can handle more extensive projects over their lifetime without the need for frequent blade replacement.

3. Types of Wet Saw Tile Cutters

Selecting the right type of wet saw tile cutter is critical to achieving the desired results in tile cutting projects. From handheld models to more robust tabletop and overhead motor wet saws, each type offers unique advantages tailored to different cutting needs and work environments. This section outlines the main types and includes specific models to consider.

Handheld Wet Saws

Handheld wet saws are designed for mobility and convenience, perfect for making quick cuts on tile already installed or for use in areas where larger, stationary saws cannot operate.

- Portability: Easily carried and manipulated, ideal for small spaces and simple cuts.

- Flexibility: Suitable for cutting tiles in situ or on an already installed surface.

- Power: Generally less powerful than larger saws but sufficient for standard tile thicknesses.

Example Products:

| Product Name | Blade Size | Power | Best For |

|---|---|---|---|

| Ryobi 4-inch Handheld Wet Saw | 4 inches | 12 amps | Small, quick cuts and touch-up work |

| Workforce 7-inch Handheld Tile Cutter | 7 inches | 10 amps | Larger tiles and more frequent use |

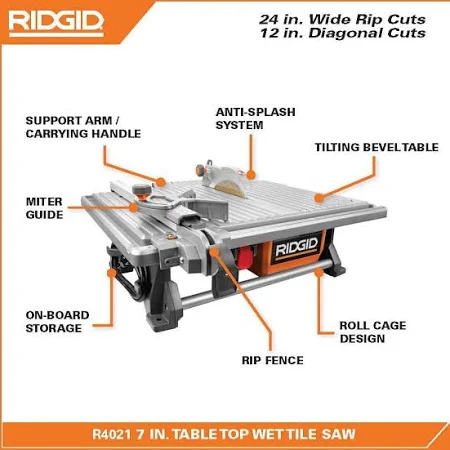

Tabletop Wet Saws

Tabletop wet saws are the go-to choice for most professional tile setters due to their stability, precision, and ability to handle larger projects.

- Stability: Mounted on a table, which provides a steady cutting surface.

- Precision: Larger blade and more powerful motor allow for cuts with greater accuracy.

- Capacity: Suitable for larger and thicker tiles, offering extended cutting lengths and depths.

Example Products:

| Product Name | Blade Size | Power | Best For |

|---|---|---|---|

| Diamond Blade Benchtop Wet Saw | 10 inches | 15 amps | High-volume cutting and thick materials |

| Best Wet Saw Tile Cutter Pro 850 | 8 inches | 13 amps | Versatile cutting with high precision |

Overhead Motor Wet Saws

Overhead motor wet saws provide the highest level of precision among wet saws, with a setup that allows for complex cuts, such as bevels and miters.

- Precision Control: Blade is suspended over the tile, offering precise control over depth and angle.

- Complex Cuts: Ideal for specialty cuts, including bevels and compound miters.

- Power and Durability: Often equipped with the most powerful motors and durable components designed for heavy use.

Example Products:

| Product Name | Blade Size | Power | Best For |

|---|---|---|---|

| Ryobi Overhead Motor Wet Saw | 10 inches | 15 amps | Professional use, complex and precision cuts |

| Workforce Overhead Pro Cutter | 12 inches | 17 amps | Large-scale projects requiring maximum precision |

Wet Saw Tile Cutter Top Products

4. Features to Consider When Buying a Wet Saw Tile Cutter

When selecting a wet saw tile cutter, various features contribute to the tool’s performance, suitability, and ease of use for specific projects. Here’s a detailed guide on what to consider to ensure you choose the best wet saw tile cutter for your needs.

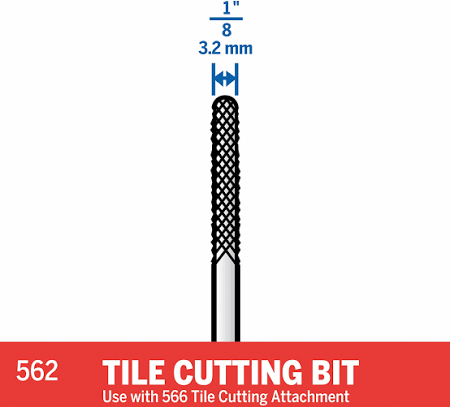

Blade Type and Size

The blade is a critical component of any wet saw, impacting the types of materials it can cut and the quality of the cut.

- Diamond Blades: Most wet saws utilize diamond blades for their durability and ability to cut through tough materials such as porcelain and stone.

- Blade Size: The size of the blade determines the maximum cutting depth. Common sizes include 7-inch blades found in models like the Workforce Wet Saw Tile Cutter and larger 10-inch blades typical of more robust models.

Considerations:

- Choose a blade size that matches the thickness of the tiles you plan to cut.

- Ensure the blade is suitable for the type of tile material to avoid chipping or inefficient cuts.

Cutting Capacity and Depth

The ability of the wet saw to handle the dimensions of your tiles is paramount.

- Cutting Capacity: Refers to the maximum length and width of the tile that can be cut with the saw.

- Depth Adjustment: Allows the blade to be set for different thicknesses of tile, which is crucial for achieving precise cuts without damaging the tile or the tool.

Considerations:

- Check the maximum crosscut and diagonal cut capabilities, especially if working with large format tiles.

- Ensure the saw can perform plunge cuts if you need to make cuts for outlets or switches.

Portability and Size

The physical dimensions and ease of transport of the wet saw can affect where and how the tool can be used.

- Weight and Size: Determines the saw’s mobility and storage requirements.

- Compact Designs: Such as the Ryobi Wet Saw Tile Cutter, are ideal for DIYers or professionals who need a portable solution for various job sites.

Considerations:

- For frequent onsite jobs, lightweight and compact models are preferable.

- For stationary workshop settings, larger, more stable saws may be beneficial.

Power and Precision

The motor’s power in a wet saw directly influences its cutting performance and the types of tiles it can handle.

- High-Power Motors: Ensure smooth, continuous operation through dense materials without bogging down.

- Variable Speed Settings: Allow for adjustments based on the material type and cut required, providing better control and results.

Considerations:

- Higher horsepower is necessary for cutting tougher materials like thick stone or marble.

- Precision is key for complex patterns and fine detail work, so look for models with excellent blade stability and adjustable speed controls.

Additional Features

Modern wet saws come equipped with various features that enhance usability and accuracy.

- Laser Guides: Project a straight line across the tile, which helps in making precise cuts.

- LED Lights: Improve visibility, especially useful in low-light conditions or for detailed work.

- Water Recycle Systems: Keep the water clean and reduce the need to refill, making the saw more efficient and easier to maintain.

Considerations:

- Laser guides and LED lights are invaluable for projects requiring high accuracy.

- Look for models with a robust water management system to ensure the workspace remains clean and the cutting process efficient.

5. Best Wet Saw Tile Cutters on the Market

Selecting the best wet saw tile cutter involves comparing several top models to determine which offers the optimal balance of features, performance, and price. This review covers three leading models that are popular among both DIY enthusiasts and professional contractors.

Product 1: Ryobi 7-inch Wet Saw Tile Cutter

Features:

- Blade Size: 7-inch diamond cutting wheel.

- Motor: 1.5 horsepower for robust cutting power.

- Cutting Capacity: Cuts material up to 1.25 inches thick and 20 inches long.

Pros:

- Compact Design: Lightweight and portable, ideal for smaller workspaces and easy transport.

- Oversized Steel Frame: Provides increased stability during cutting, enhancing precision.

- Integrated Water Reservoir: Keeps the blade wet, reducing dust and debris.

Cons:

- Limited Cutting Depth: Not suitable for very thick materials like pavers or natural stone.

- Noise Level: Tends to be louder than some other models.

Product 2: Diamond Blade Benchtop Wet Saw Tile Cutter

Features:

- Blade Size: 10-inch professional-grade diamond blade.

- Motor: 2.5 horsepower motor that can handle heavy-duty tasks.

- Cutting Capacity: Capable of handling tiles up to 3 inches thick and 36 inches in length.

Pros:

- High Cutting Capacity: Excellent for large tiles and thicker materials, offering versatility.

- Precision Control: Comes with a cutting guide and miter gauge for accurate angle cuts.

- Durable Construction: Built to withstand heavy use in commercial environments.

Cons:

- Size and Weight: Quite bulky and heavy, making it less portable.

- Price: Higher cost, making it a significant investment.

Product 3: Workforce Wet Saw Tile Cutter

Features:

- Blade Size: 7-inch diamond blade.

- Motor: 1.25 horsepower, suitable for standard tiling materials.

- Cutting Capacity: Designed to cut tiles up to 24 inches in length and 1 inch thick.

Pros:

- Versatility: Good for both porcelain and ceramic tiles.

- Water Splash Guard: Minimizes mess, keeping the work area cleaner.

- Adjustable Cutting Guide: Allows for precise cuts at various angles.

Cons:

- Limited Power: Not ideal for very dense materials or prolonged heavy-duty use.

- Build Quality: Some components may require frequent adjustment or replacement with heavy use.

Comparison and Recommendations

When comparing these models, consider the specific requirements of your projects:

- For DIY Projects and Light Use: The Ryobi 7-inch Wet Saw Tile Cutter offers a good balance of portability and power, suitable for home renovations.

- For Professional Use and Heavy-Duty Cutting: The Diamond Blade Benchtop Wet Saw Tile Cutter is the best choice, with its high capacity and power to handle a wide range of materials and sizes.

- For Moderate Use and Versatility: The Workforce Wet Saw Tile Cutter strikes a balance between the two, offering decent power and the ability to make precision cuts without the bulk of larger units.

Tile Cutters

6. How to Use a Wet Saw Tile Cutter Safely and Effectively

Using a wet saw tile cutter allows for precise and clean cuts, but it’s important to handle the tool correctly to ensure safety and achieve the best results. Here’s a detailed guide to setting up and operating your wet saw tile cutter, along with important safety tips.

Step-by-Step Guide to Setting Up and Using Your Wet Saw

Step 1: Assemble the Wet Saw

- Assemble your tool according to the manufacturer’s instructions. Models like the Ryobi Wet Saw Tile Cutter and Workforce Wet Saw Tile Cutter usually come with a detailed manual.

Step 2: Prepare the Work Area

- Ensure your workspace is stable, level, and close to a water source if your saw does not have a built-in reservoir.

- Set up adequate lighting, especially if working with intricate cuts or smaller tiles.

Step 3: Install the Correct Blade

- Choose a diamond blade suitable for the tile material. Ensure it is tightly secured and aligned properly.

Step 4: Fill the Water Reservoir

- Fill the reservoir with clean water to keep the blade cool and minimize dust. Check water levels regularly.

Step 5: Measure and Mark Your Tiles

- Accurately measure and mark your tiles using a pencil or marker for precision cutting.

Step 6: Make the Cut

- Turn on the saw and let the blade reach full speed before cutting.

- Feed the tile slowly and gently into the blade, keeping hands clear of the cutting path.

- For models like the Diamond Blade Benchtop Wet Saw, use guides to maintain straight cuts.

Step 7: Turn Off and Clean

- After cutting, turn off the saw and clean any debris from the cutting area and the machine. This helps maintain the saw’s performance and longevity.

Safety Tips and Precautions

- Wear Appropriate Safety Gear: Always wear eye protection, ear protection, and a dust mask.

- Check the Equipment: Before each use, ensure there are no damaged parts and that the blade is sharp and secure.

- Avoid Overloading the Saw: Do not push the tile into the blade too quickly; let the blade do the work.

- Keep Water Levels Optimal: Always ensure there is enough water to cool the blade during cuts.

- Secure the Tile: Use clamps or a fence if available, to hold the tile securely during cutting.

7. Maintenance and Care for Wet Saw Tile Cutters

Regular maintenance and proper care ensure your wet saw tile cutter remains in optimal working condition, extending its life and maintaining its efficiency.

Routine Maintenance Tasks

- Daily Cleaning: Remove tile residue and debris after each use. Clean the water reservoir and ensure no sludge builds up.

- Blade Inspection and Replacement: Regularly check the blade for wear or damage and replace it as needed. A dull blade can lead to poor cutting performance and increased safety risks.

- Check Moving Parts: Lubricate and check all moving parts regularly to ensure smooth operation. This includes the motor, cutting head, and sliding mechanism.

- Water System Maintenance: For models like the Diamond Blade Wet Saw, which may have more complex water systems, ensure hoses and pumps are clear of blockages and functioning correctly.

Troubleshooting Common Issues

- Motor Won’t Start: Check the power supply, fuses, and motor brushes. Refer to the manufacturer’s troubleshooting guide specific to models like the Ryobi Wet Saw Tile Cutter.

- Uneven Cuts: Ensure the blade is properly aligned and the tile is securely held against the guide. Also, check the blade for wear and replace it if necessary.

- Excessive Vibration or Noise: Tighten any loose components and check the saw’s base to ensure it is on a stable surface.

8. Creative Projects Using a Wet Saw Tile Cutter

A wet saw tile cutter is not only for cutting standard tiles for bathrooms and kitchens but can also be used for various creative home improvement projects.

DIY Home Improvement Ideas

- Custom Tile Backsplashes: Create a unique backsplash for your kitchen or bathroom using a mix of different tile materials and shapes.

- Tiled Tabletops: Cut tiles to size to create beautiful, durable tabletops for indoor or outdoor furniture.

- Decorative Garden Paths: Use the wet saw to shape tiles or pavers into intricate designs for garden paths or patios.

Tips for Getting the Best Results

- Plan Your Project in Detail: Before starting, have a clear design in mind and all materials measured and ready.

- Use Quality Materials: Invest in high-quality tiles that will cut cleanly and look great.

- Practice Makes Perfect: Before starting on the actual project, practice making cuts on extra tiles to ensure precision when it counts.

By understanding the different types of wet saw tile cutters like the Ryobi Wet Saw Tile Cutter, Workforce Wet Saw Tile Cutter, and Diamond Blade Benchtop Wet Saw, and following these guidelines, you can safely and effectively manage any tile cutting project and explore creative DIY possibilities.

FAQs About Wet Saw Tile Cutters

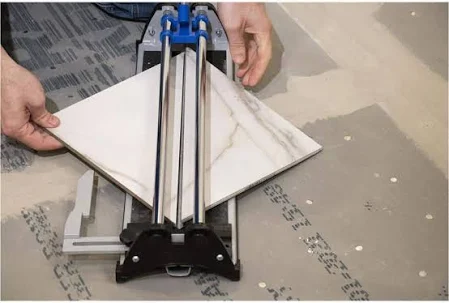

Is it better to use a tile cutter or wet saw?

The choice between a tile cutter and a wet saw depends on the type of tile material and the complexity of the project. Tile cutters are great for straight cuts on thinner ceramic tiles and are more portable. Wet saws, however, are preferred for cutting thicker materials like porcelain or stone and for making intricate cuts, such as angles and curves. For projects requiring high precision and multiple types of cuts, a wet saw is typically the better choice.

Can you cut tiles with a wet saw?

Yes, you can cut tiles with a wet saw, and it is one of the best tools for this purpose. Wet saws are designed to cut through a variety of tile materials, including ceramic, porcelain, glass, and natural stone, with precision and minimal chipping.

How do you stop tile from chipping when cutting with a wet saw?

To prevent chipping when cutting tiles with a wet saw, ensure the blade is sharp and of high quality, the tile is securely placed, and the cutting speed is not too fast. Feeding the tile slowly and steadily into the saw and using a blade designed for the tile material can also help reduce chipping.

Are wet tile cutters any good?

Wet tile cutters are highly effective tools for cutting tiles, especially when precision and cleanliness are important. They are ideal for cutting a wide range of tile materials, providing clean, precise cuts with the help of a water-cooled diamond blade that also reduces dust.

How much mess does a wet saw make?

While wet saws do use water to cool the blade and reduce dust, they can still create a mess primarily due to water spray and slurry (a mixture of water and tile debris). The amount of mess is generally manageable but does require preparation to contain the water and clean up afterward.

What is the hardest tile to cut?

Porcelain tiles are generally considered the hardest to cut due to their density and hardness. These tiles require a diamond blade and often a wet saw to ensure clean, precise cuts without damage.

Do you cut tile face up or down?

When using a wet saw, you should cut tile face up. This orientation ensures you can see the cut line and allows for greater accuracy and fewer mistakes. Cutting face up also reduces the risk of chipping the visible surface of the tile.

What can I use instead of a wet tile saw?

For simple, straight cuts on ceramic tiles, you can use a manual tile cutter (score and snap cutter). For smaller or thinner tiles, tile nippers or a glass cutter might also work. However, for complex cuts or harder materials like porcelain and stone, a wet saw is generally irreplaceable.

How messy is a wet tile saw?

Wet tile saws can be messy as they use water to cool the cutting blade, which can spray and create a slurry. Proper setup with water containment systems and cleanup plans can minimize the mess.

Should you tape tile before cutting?

Taping the cut line on a tile with painter’s tape can help reduce chipping and allow for a cleaner cut. The tape supports the tile surface, minimizing splintering and providing a clear line to follow.

Why do my tiles keep cracking when I cut them?

Tiles may crack during cutting if the tile cutter is not appropriate for the tile material, the blade is dull or inappropriate, the tile is not properly supported, or the cutter is applied with uneven pressure. Ensuring the correct setup and using a sharp blade suitable for the tile material can help prevent cracking.

How do you mark tile for a wet saw?

To mark a tile for cutting with a wet saw, use a grease pencil or a washable marker, which provides visibility and won’t wash off easily when exposed to water during the cutting process.

How to cut tile with a wet saw without chipping?

To cut tile without chipping, use a fresh, high-quality diamond blade appropriate for the tile material, ensure the tile is fully supported and feed the tile into the blade slowly and steadily. Keeping the blade wet and making sure it is not forced into the tile can also help minimize chipping.

Why is my manual tile cutter breaking tiles?

A manual tile cutter may break tiles if the score is not deep enough, the scoring wheel is dull, or excessive force is used during the snapping process. Ensure the tool is in good condition and that appropriate pressure is applied evenly.

Can hairline cracks in tile be repaired?

Hairline cracks in tile can be repaired with a clear epoxy or resin designed for ceramic or porcelain repair. The repair will stabilize the crack and can be colored to match the tile, making it less noticeable. However, if structural integrity is compromised, replacing the tile is recommended.