Diamond blades for grinders are essential tools in various cutting applications, offering precision and efficiency. Used predominantly in construction and renovation, these blades cut through hard materials such as tile, stone, and concrete with ease. Their durability and sharpness make them ideal for both professional contractors and DIY enthusiasts.

Overview of the Importance and Uses of Diamond Blades in Grinders

- Precision Cutting: Diamond blades provide clean and precise cuts, essential for delicate materials like porcelain and glass tiles.

- Versatility: These blades are not only used in grinders but also fit into other tools like circular saws and tile saws, making them versatile for multiple cutting tasks.

- Durability: Made from hard-wearing materials, diamond blades can outlast standard blades, offering long-term value.

Key Uses Include:

- Construction Projects: From cutting bricks for walls to shaping stone for landscaping.

- Home Renovation: Ideal for remodeling kitchens and bathrooms, especially for cutting tiles and backsplashes.

- Specialty Materials: Some blades are specifically designed to cut through dense and tough materials like granite or ceramic.

Understanding the different types of diamond blades can help users choose the right one for their specific needs:

- Wet Saw Diamond Blade: Best used for projects requiring extensive cutting, minimizing dust and cooling the blade.

- Circular Saw Tile Blade: Perfect for making quick, straight cuts on tiles.

- Diamond Grinder Blades: These blades are excellent for detailed work on smaller surfaces.

By choosing the correct diamond blade, users can enhance their cutting precision and efficiency, ensuring professional-grade results in their projects. Whether cutting porcelain tile, shaping marble, or undertaking a major construction project, the right diamond blade for your grinder is crucial for success.

Top Blades

Understanding Diamond Blades

Diamond blades are indispensable tools in cutting hard materials with precision. Knowing about the different types of diamond blades can help you choose the right one for your specific needs, enhancing efficiency and outcomes in your projects.

Types of Diamond Blades

Various tasks require specific diamond blades. Here’s a closer look at the types available and their ideal applications, with specific product names mentioned for clarity.

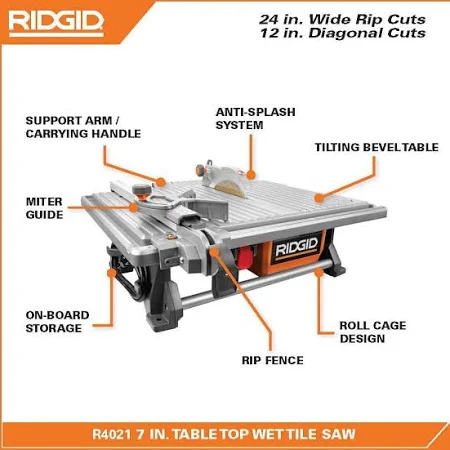

- Wet Saw Diamond Blade: These blades are designed for use in wet conditions to minimize dust and cool the blade during extensive cutting sessions. Ideal for cutting porcelain tiles, stone, and other hard materials.

- Product Example: Husky 10-inch Wet Diamond Blade for Porcelain Tile

- Circular Saw Tile Blade: Perfect for quick and clean cuts, these blades are typically used with handheld circular saws to cut tiles and other fragile materials accurately.

- Product Example: DEWALT 4.5-inch Circular Saw Tile Blade

- Diamond Grinder Blades: Used for detailed grinding work, these blades are suited for smaller surfaces or intricate areas.

- Product Example: Makita 7-inch Turbo Diamond Grinding Cup Wheel

Specialized Blades for Specific Materials

- Best Blade to Cut Porcelain Tile: Specially designed to handle the brittle nature of porcelain tiles without causing chips or cracks.

- Product Example: QEP 7-inch Diamond Blade for Wet Tile Saws

- Glass Blade for Tile Saw: Crafted to cut through glass tiles cleanly to prevent breakage and ensure smooth edges.

- Product Example: RIDGID 7-inch Glass Tile Diamond Blade

- Diamond Blade for Wet Saw: These blades are particularly effective for wet cutting operations, offering precise cuts with reduced dust and heat.

- Product Example: Norton 10-inch Wet Cutting Continuous Rim Diamond Blade

Innovative Cutting Solutions

- Tile Cutting Multi Tool Blade: This versatile blade is perfect for detailed and intricate cutting tasks across various materials.

- Product Example: Bosch Multi Tool Tile Cutting Blade

- Diamond Cutting Disc for Tiles: Designed for high precision in cutting ceramic and porcelain tiles.

- Product Example: GoYonder 4.5-inch Diamond Cutting Disc for Tiles

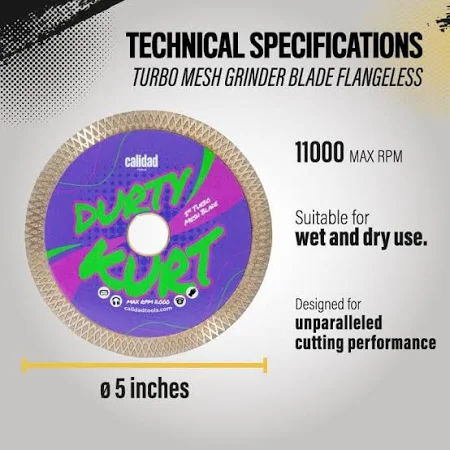

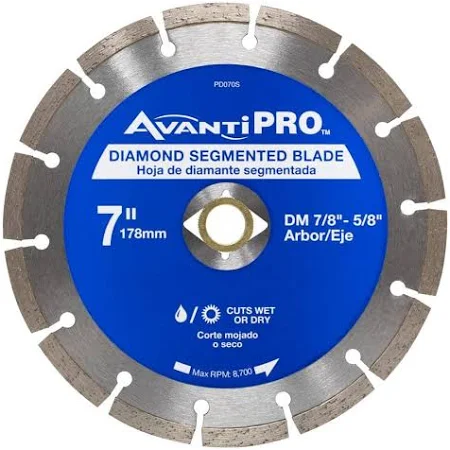

- 7-inch Diamond Blade: An all-purpose blade suitable for both dry and wet cutting conditions, providing flexibility across different cutting environments.

- Product Example: Diablo 7-inch Diamond Masonry Blade

By selecting the right diamond blade for your grinder or saw, you ensure more efficient and precise cuts, making your project easier and enhancing the final quality. Each blade type mentioned here is tailored to specific materials and uses, allowing you to tackle a variety of cutting tasks with confidence.

Wet Saw Tile Cutter

Materials and Technology

Understanding the materials and technologies behind diamond blades can greatly enhance their effectiveness in various cutting tasks. This section explores the crucial elements that make diamond blades indispensable for precision cutting.

Diamond Blade Sharpening Stone

A diamond blade sharpening stone is essential for maintaining the sharpness and longevity of diamond blades. It ensures that each cut remains precise and efficient.

- Product Example: DMT Diamond Sharpening Stone – Ideal for restoring the cutting edge on blades of all types.

Porcelain Grinder Blade

Specifically designed for cutting porcelain, these grinder blades cut cleanly through porcelain tiles without chipping or cracking the delicate material.

- Product Example: DEWALT XP4 Porcelain Grinder Blade – Engineered for optimum cutting performance on porcelain tiles.

Ceramic Tile Blades

Ceramic tile blades are tailored to cut ceramic tiles with minimal dust and maximum accuracy. Their design reduces the risk of tile damage during cutting.

- Product Example: Bosch Continuous Rim Diamond Blade for Ceramic Tiles – Provides clean, chip-free cuts.

Granite Blades

Granite blades are robust and designed to tackle the hardness of granite with ease. These blades ensure smooth cuts and are built to withstand the rigors of cutting through such a tough material.

- Product Example: GoYonder Diamond Blade for Granite Cutting – Known for its durability and precision in cutting granite slabs.

Key Features of These Blades:

| Blade Type | Key Feature | Suitable for Material |

|---|---|---|

| Sharpening Stone | Extends the life of diamond blades | All types of diamond blades |

| Porcelain Grinder Blade | Minimizes chips in porcelain tiles | Porcelain |

| Ceramic Tile Blades | Designed for smooth, precise cuts | Ceramic Tiles |

| Granite Blades | High durability for tough materials | Granite |

Cutting Edge Technology in Diamond Blades

Diamond blades are embedded with synthetic diamonds, bonded to the blade’s edge, which allows them to cut through hard materials effectively. The diamonds are exposed continually as the blade wears down, which keeps the blade sharp over time.

- Advanced Applications:

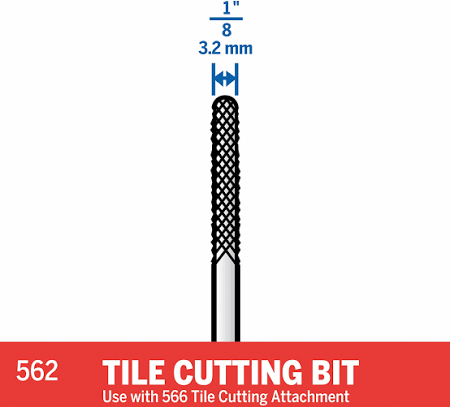

- Tile Cutting Disc for Angle Grinder: Perfect for quick cuts in tile and stone.

- Best Diamond Blade for Porcelain Tile: Offers precision and longevity, making it ideal for porcelain tile projects.

- Diamond Cutter for Tiles: Provides intricate and detailed cuts, essential for complex tile designs.

By selecting the right blade based on the material you intend to cut, you ensure optimal performance and outcomes, which is crucial for professional and home projects alike. The development of these specialized blades reflects the evolving needs of industries that require precision cutting tools.

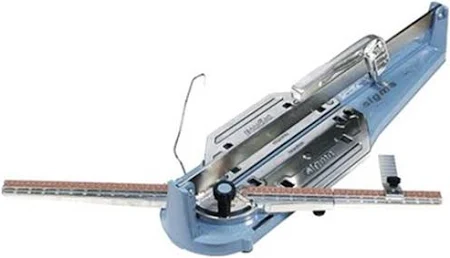

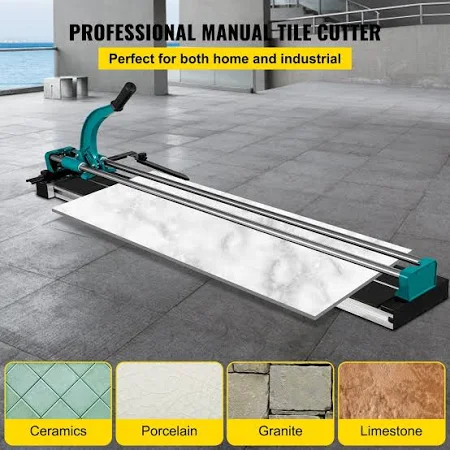

Large Format Tile Cutter

Choosing the Right Diamond Blade

Selecting the appropriate diamond blade for your cutting needs ensures efficiency and effectiveness in your projects, whether they involve construction, renovation, or crafting.

By Size and Type

The size and type of diamond blade you choose depend largely on the material you intend to cut and the precision required.

- 7 Inch Diamond Blade for Grinder: Ideal for general purpose cutting on grinders, suitable for a variety of materials.

- Product Example: DEWALT DW4701 Industrial 7-Inch Dry or Wet Cutting Segment Diamond Blade.

- 4 Inch Tile Saw Blade: Perfect for smaller or more precise tile cutting tasks.

- Product Example: QEP 6-4001Q 4-Inch Diamond Blade For Wet or Dry Tile Saws.

- Best 7-inch Tile Saw Blade: Chosen for its superior performance in cutting through thick and tough tiles.

- Product Example: Bosch DB743S 7-Inch Continuous Rim Diamond Blade.

Specialized Blades

For specific materials, specialized blades are designed to optimize cutting and minimize damage to delicate substances like porcelain and glass.

- Best Blade to Cut Porcelain Tile: Engineered to cut smoothly without chipping.

- Product Example: MK Diamond 158434 7″ MK-225 Hot Dog Premium Thin-Rim Blade.

- Glass Blade for Tile Saw: Specially formulated to handle the brittle nature of glass tiles.

- Product Example: TOOLEAGUE 10 Inch Glass Tile Blade for Wet Tile Saw, Diamond Cutting Blade.

- Diamond Blade for Cutting Stone: Built to tackle hard stone materials efficiently.

- Product Example: GoYonder 5-Inch Super Thin Diamond Saw Blade for Cutting Porcelain Tiles, Granite Marble Ceramics.

- Best Diamond Blade for Concrete: Designed for high endurance and fast cutting through concrete and other masonry materials.

- Product Example: DEWALT Diamond Blade for Masonry, Dry Cutting, Continuous Rim, 7-Inch (DW4712).

Considerations When Choosing a Diamond Blade:

- Material Compatibility: Ensure the blade is suitable for the material you are cutting to avoid damage and ensure clean cuts.

- Wet vs. Dry Cutting: Some blades are designed specifically for wet or dry cutting environments; choose based on your setup.

- Cutting Speed and Finish: Consider how quickly and cleanly you need to make your cuts, as specialized blades may enhance performance in these areas.

By carefully selecting the right diamond blade for your tool and material, you can achieve optimal cutting results, saving time and resources while increasing the lifespan of your blades. Whether you are cutting tiles, concrete, or specialty materials, the right blade makes all the difference.

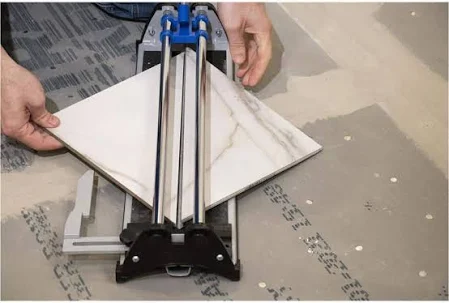

Small Tile Cutter

Application-Specific Recommendations

When selecting diamond blades, it’s crucial to consider the specific applications they’ll be used for. Different materials require different blades for optimal cutting performance.

Tile Cutting

For those involved in tile cutting, selecting the right blade can mean the difference between a clean job and a botched surface.

- Porcelain Tile Blades: These blades are engineered to cut through porcelain with minimal chipping.

- Product Example: Montolit 4.5-Inch Diamond Blade for Porcelain.

- Best Wet Saw Blade for Porcelain Tile: Designed to work with wet saws, this blade ensures smooth cuts and longer blade life.

- Product Example: QEP 6-7003Q 7-Inch Diameter Continuous Rim Premium Diamond Blade for Wet Cutting Porcelain and Ceramic Tile.

- Tile Blade for Circular Saw: Allows for precise cuts on a circular saw, suitable for more portable cutting jobs.

- Product Example: DEWALT DW4765 4.5-Inch Premium XP4 Tile Blade Wet.

- Tile Cutter for Porcelain: Specifically designed for snap cutters, this blade is perfect for quick, straightforward porcelain tile cuts.

- Product Example: Sigma 2B3 26-Inch Pull Handle Tile Cutter.

Cutting Other Materials

Diamond blades aren’t just for tile. They’re also ideal for other hard materials, providing efficiency and precision.

- Best Diamond Blade for Cutting Glass Tile: These blades are crafted to cut glass tiles without causing cracks or chips.

- Product Example: Bosch DB1069 10-Inch Continuous Rim Diamond Blade.

- Porcelain Saw Blade: A great option for those needing to cut porcelain slabs or large tiles.

- Product Example: Lackmond Beast Pro Porcelain Saw Blade – 10″ Hard Tile Cutting Tool with Thin Kerf Cutting Edge & 5/8″ Arbor.

- Ceramic Tile Cutting Wheel: This wheel is designed for clean and precise cuts in ceramic tiles.

- Product Example: Dremel US540-01 Ultra-Saw 3.5-Inch Tile Diamond Blade.

Each of these tools and blades is tailored to specific materials and cutting scenarios, ensuring the best possible outcomes for your projects. Here’s a quick reference table for easy selection:

| Blade Type | Material | Best Used For | Product Example |

|---|---|---|---|

| Porcelain Tile Blades | Porcelain | Minimal chipping cutting | Montolit 4.5-Inch Diamond Blade |

| Wet Saw Blade for Porcelain Tile | Porcelain | Wet cutting for clean edges | QEP 6-7003Q 7-Inch Diamond Blade |

| Tile Blade for Circular Saw | Various | Portable and precise cutting | DEWALT DW4765 4.5-Inch Tile Blade |

| Tile Cutter for Porcelain | Porcelain | Manual snap cutting | Sigma 26-Inch Tile Cutter |

| Diamond Blade for Cutting Glass Tile | Glass | Cutting glass tiles without chips | Bosch DB1069 10-Inch Blade |

| Porcelain Saw Blade | Porcelain | Cutting large porcelain tiles or slabs | Lackmond Beast Pro 10″ Blade |

| Ceramic Tile Cutting Wheel | Ceramic | Precise cuts in ceramic tiles | Dremel US540-01 3.5-Inch Blade |

Choosing the right blade for the job not only enhances performance but also prolongs the life of both your tools and the blades themselves, ensuring that each cut is as precise as the first.

Brutus Tile Cutter

Tips and Techniques

Maximizing the performance of diamond blades involves proper usage, regular maintenance, and adherence to safety guidelines. Below, we delve into effective strategies and best practices for using diamond blades in various cutting applications.

Using Diamond Blades

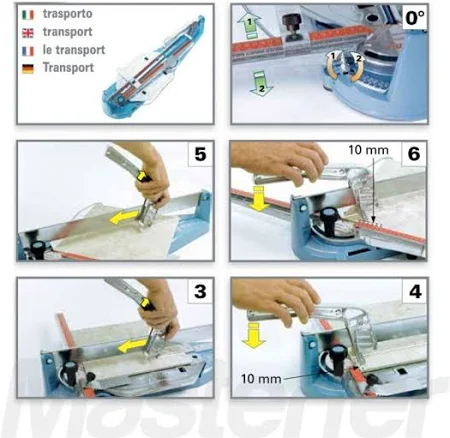

- Using Diamond Blades: To achieve the best results, ensure the blade matches the material type and the tool. For instance, using a Wet Saw Tile Cutter is ideal for large volume tile jobs to ensure clean and precise cuts.

- How to Sharpen Diamond Blades: Regular sharpening of diamond blades can significantly extend their lifespan. Sharpening involves running the blade through a dressing stone or a specific diamond blade sharpening stone to expose new diamond grit.

- Cutting Blades for Grinder: When using diamond blades with grinders, select the appropriate size and type for the material. For example, Electric Tile Cutters often offer specialized blades for detailed and intricate cuts.

Best Practices for Diamond Cutter for Tiles

- Best Tile Cutter for Porcelain: Use a Best Tile Cutter For Porcelain for precision and to avoid chipping in delicate porcelain tiles.

- Large Format Tile Cutter: For handling larger tiles, a Large Format Tile Cutter ensures accuracy and ease of cutting without breaking the tile.

- Sigma Tile Cutter 24 Inch: The Sigma Tile Cutter 24 Inch is perfect for professional tilers looking for reliability and precision in repetitive cuts.

Safety and Maintenance

- Handling and Safety Tips: Always wear appropriate safety gear such as gloves and eye protection. Ensure the blade is securely attached to the tool and inspect it for damage before use to prevent accidents.

- Maintenance and Care for Longevity: Clean the blade after each use to remove any debris. Store diamond blades in a dry and safe environment to prevent rust and wear. Regularly check the blade for wear and replace it if you notice significant reductions in performance.

Learning and Resource Links

- How to Cut Tile: Learn the techniques and tips for cutting tiles effectively at How To Cut Tile.

- How to Tile a Shower: Detailed instructions for tiling a shower can be found at How to Tile a Shower.

- How To Grout Tile: For finishing touches, mastering grouting is essential. Visit How To Grout Tile for guidance.

- Small Tile Cutter: For smaller projects, consider a Small Tile Cutter, which is easier to manage and store.

- Brutus Tile Cutter: The Brutus Tile Cutter is an excellent option for those seeking a robust tool for regular use.

- Vevor Tile Cutter: Explore options like the Vevor Tile Cutter for versatile cutting capabilities in various tile types.

By adhering to these tips and utilizing the recommended tools and techniques, you can enhance the efficiency and safety of your tile cutting projects, ensuring professional results every time.

FAQs

Can I use a diamond blade on a grinder?

Yes, diamond blades like the Makita 7-inch Turbo Diamond Grinding Cup Wheel can be used on grinders for various cutting, grinding, and shaping applications on materials like tile, concrete, and stone.

What will a diamond blade cut?

Diamond blades can cut through a wide range of materials including concrete, tile, stone, porcelain, ceramic, glass, and some metals.

What is the purpose of a diamond blade?

The purpose of a diamond blade is to provide high-quality, precise cuts in hard materials with minimal chipping and faster cutting speeds.

Are diamond blades real diamonds?

Yes, diamond blades contain real industrial diamonds embedded in the cutting edge of the blade to enhance their cutting performance.

Is diamond good for grinding?

Yes, diamond is excellent for grinding because it offers great durability and precision. Diamond grinding wheels, such as the DEWALT Diamond Cup Wheels, are commonly used for preparing concrete surfaces.

What is the difference between diamond blade and carbide blade?

Diamond blades use industrial-grade diamonds on the cutting edge, offering superior durability and are used for hard materials. Carbide blades, like the Bosch T128BHM3 3-Piece 3-1/4 In. 14 TPI Carbide Teeth Jigsaw Blade, use carbide tips and are ideal for cutting softer materials like wood and plastic.

How deep will a 14″ diamond blade cut?

A 14-inch diamond blade can typically cut to a depth of about 5 inches, depending on the blade design and the material being cut.

Is diamond a good cutting tool?

Yes, diamond is considered one of the best cutting tools due to its hardness and durability, making it ideal for cutting a variety of tough materials.

What is the difference between a diamond blade and a steel saw blade?

A diamond blade has diamond particles attached to its cutting surface for hard material applications, whereas a steel saw blade is generally used for softer materials and may wear out faster when used on hard materials.

Will a diamond blade cut rock?

Yes, a diamond blade like the GoYonder Diamond Saw Blade for Cutting Porcelain Tiles Granite Marble Ceramics can cut rock and other very hard materials.

What is the best blade to cut metal?

For metal, a carbide-tipped blade like the Diablo Steel Demon Ferrous Metal-Cutting Saw Blade is typically best, as it is designed to handle the hardness of metals efficiently.

How do I choose a diamond blade?

Choose a diamond blade based on the material to be cut, the type of cut desired (wet or dry), and the power tool used. For example, the Norton Wet Cutting Continuous Rim Diamond Blade is ideal for wet cutting of tiles and stone.

Can a diamond blade cut rebar?

Yes, diamond blades like the Bosch DB1041S 10-Inch Segmented Rim Diamond Blade can cut rebar, especially if it’s designed for hard material applications.

Can a diamond blade be sharpened?

Yes, diamond blades can be sharpened by cutting into abrasive materials such as a concrete block or by using a dressing stone.

Do diamond drill bits have real diamonds?

Yes, diamond drill bits like the DEWALT Diamond Drill Bit have small industrial diamonds embedded into their tips to enhance drilling performance in hard materials.

Can you grind with a diamond blade?

Yes, diamond blades can be used for grinding, especially diamond grinding wheels or cups designed for surface preparation.

Can a grinder scratch a diamond?

Generally, no. Diamonds are among the hardest known materials, and it is unlikely for a standard grinder to scratch a diamond.

Do diamonds make good knives?

While diamonds themselves are very hard, they are not used for making knife blades because they can be brittle. However, diamond-coated blades are used for their abrasive properties to cut through hard materials.

How long does a diamond blade last?

The lifespan of a diamond blade depends on various factors including the material being cut, cutting method, and frequency of use. Generally, they can last anywhere from several hours to over a hundred hours of cutting time.

Which is stronger, carbide or diamond?

Diamond is harder than carbide, making it stronger in terms of cutting capabilities and resistance to wear when used on very hard materials.

Do carbide blades get dull?

Yes, carbide blades can get dull over time, especially when used on abrasive materials. They require periodic sharpening or replacement depending on usage.