The Cortag Tile Cutter is renowned for its robust design and precision, making it a top choice for both DIY enthusiasts and professional tilers. The product lineup, including popular models like the Cortag Mega 125 and the Cortag Master Plus 125, is engineered to accommodate various tile cutting needs, from porcelain to ceramic. These cutters are designed to deliver clean, efficient cuts with minimal effort, enhancing productivity and ensuring high-quality results.

Importance of Choosing the Right Tile Cutter

Selecting the right tile cutter is critical for several reasons:

- Accuracy: Proper tools like the Cortag tile cutters ensure precise cuts, reducing material waste and improving the aesthetics of the finished project.

- Efficiency: A manual tile cutter like the Cortag models allows for quick and straightforward operation, which is crucial in large projects.

- Cost-effectiveness: Using the right tool minimizes tile breakage, thereby saving on the cost of materials.

Features of Cortag Tile Cutters

| Model | Cutting Length | Suitable for Tiles | Cutting Wheel Diameter |

|---|---|---|---|

| Cortag Mega 125 | 125 cm | Porcelain, Ceramic | 22 mm |

| Cortag Master Plus 125 | 125 cm | Ceramic, Glass | 22 mm |

These models are equipped with high-end features that set them apart in the marketplace:

- Precision Cutting Wheel: Both models come with a durable ceramic tile cutting wheel, essential for scoring and snapping tile accurately.

- Robust Construction: Designed to withstand the rigors of frequent use, making them ideal for both high-volume tile cutting and intricate work.

- Ergonomic Design: Ease of use is guaranteed with features like adjustable measuring guides and comfortable handles.

Choosing Between Cortag Mega 125 and Cortag Master Plus 125

When deciding between the Cortag Mega 125 and the Cortag Master Plus 125, consider the following:

- Tile Type: The Mega 125 is optimal for harder materials like porcelain, while the Master Plus 125 excels with both ceramic and more delicate glass tiles.

- Project Size: Both models handle up to 125 cm in length, but your specific project’s volume and the tile size can influence the best choice.

Incorporating these cutters into your toolkit not only enhances the efficiency and quality of your tile projects but also ensures that every cut is precise and clean. Whether you are outfitting a new toolkit or upgrading your existing equipment, understanding the specific capabilities and differences between these models will guide you to the right Cortag tile cutter for your needs.

Products

What is a Cortag Tile Cutter?

A Cortag Tile Cutter is a specialized tool designed for cutting and shaping tiles, which is essential in flooring, tiling, and renovation projects. This manual tile cutter stands out due to its precision, ease of use, and durability, which are particularly favored in settings where both speed and accuracy are valued.

Key Features of Cortag Tile Cutters

Cortag’s range of tile cutters, including the Cortag Mega 125 and Cortag Master Plus 125, is designed with professional-grade capabilities that cater to a variety of tiling materials and sizes. Here’s an in-depth look at their key features:

- High Precision Cutting: Equipped with a sharp, durable ceramic tile cutting wheel, these cutters make precise scoring on tiles, allowing for clean, straight breaks without chipping or wasting material.

- Robust Construction: Made with high-quality materials, Cortag tile cutters are built to withstand the demands of heavy-duty use in commercial and residential projects.

- Ergonomic Design: Features like padded handles and adjustable measuring guides enhance comfort and ease of use, reducing fatigue during extended use.

Advanced Technology in Cortag Tile Cutters

The technology behind these tile cutters includes several advanced features that enhance their functionality and user-friendliness:

- Adjustable Measuring Guide: Allows for quick and accurate alignment and cutting of tiles, facilitating repetitive cuts with high precision.

- Interchangeable Cutting Wheels: The ability to change cutting wheels based on tile material and thickness is a standout feature, with wheels specifically designed for scoring ceramic, porcelain, and even glass tiles.

- Built-in Support Arms: These extendable arms provide stability for larger tiles, ensuring even pressure distribution during scoring and snapping.

Detailed Feature Comparison

Here’s a closer look at the specific features of the Cortag Mega 125 and Cortag Master Plus 125:

| Feature | Cortag Mega 125 | Cortag Master Plus 125 |

|---|---|---|

| Max Cutting Length | 125 cm | 125 cm |

| Tile Types | Porcelain, Ceramic, Glass | Ceramic, Glass |

| Cutting Wheel | 22 mm diamond tile cutter wheel | 22 mm ceramic tile cutting wheel |

| Support Arms | Extendable, up to 125 cm | Extendable, up to 125 cm |

| Base Material | Reinforced steel | Reinforced steel |

| Measuring Guide | Laser-engraved scales | Laser-engraved scales |

These features underscore why Cortag tile cutters are highly regarded among professionals for their reliability and performance in tile cutting. Whether you are involved in intricate tile installations or need a robust tool for straightforward tile cutting, Cortag provides efficiency and precision that can significantly enhance the quality of your work.

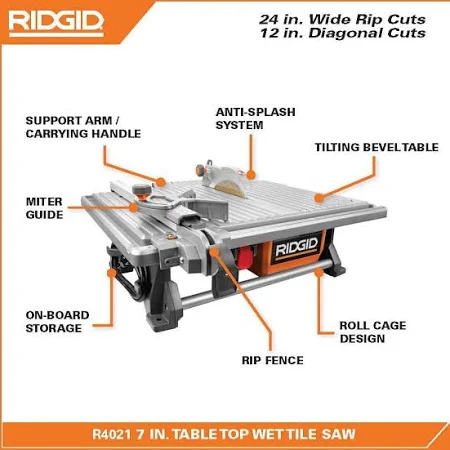

Wet Saw Tile Cutter

Benefits of Using a Cortag Tile Cutter

Cortag tile cutters are revered in the tiling industry for their superior precision, robust construction, and versatility. Each model, such as the Cortag Mega 125 and Cortag Master Plus 125, is designed to meet specific needs of professional tilers and DIY enthusiasts, ensuring that every cut contributes to a flawless finish.

Precision and Accuracy

One of the standout benefits of using a Cortag tile cutter is the exceptional precision and accuracy it offers:

- Sharp Cutting Wheels: Both models are equipped with high-quality ceramic and diamond tile cutting wheels, providing smooth scoring that reduces tile breakage and wastage.

- Exact Measurements: Enhanced with laser-engraved scales and adjustable measuring guides, these cutters ensure that each tile is cut to precise specifications, which is crucial for intricate tile patterns and tight spaces.

These features are especially beneficial when working with expensive materials like porcelain or glass, where precision is paramount to avoid costly errors.

Durability and Build Quality

Cortag’s commitment to durability and robust construction is evident in the build quality of their tile cutters:

- Reinforced Steel Base: Both the Mega 125 and the Master Plus 125 feature a heavy-duty steel base that withstands rigorous use without compromising on stability.

- Rust-resistant Components: All metal parts are coated to resist corrosion, enhancing the longevity of the cutter even under frequent use in varying conditions.

This build quality ensures that Cortag tile cutters are a long-term investment, capable of handling numerous projects over the years without deterioration in performance.

Variety of Models and Their Specific Advantages

Cortag offers a range of tile cutters, each designed to cater to different tiling needs and preferences:

| Model | Ideal for | Key Features |

|---|---|---|

| Cortag Mega 125 | Large-scale projects, porcelain tiles | Extended support arms, 22 mm diamond cutting wheel, robust base |

| Cortag Master Plus 125 | Ceramic and glass tiles, intricate patterns | Precise laser-engraved guides, ergonomic design, lighter frame for detailed work |

- Cortag Mega 125: Best suited for large, heavy-duty projects where precision with large tiles is necessary. Its extended support arms facilitate the handling of large tiles, making it an excellent choice for commercial applications.

- Cortag Master Plus 125: This model shines in settings where detailed work is prevalent, such as in decorative tiling or renovations involving glass tiles. Its lighter frame and precision-focused design provide enhanced control and ease of use for delicate cutting tasks.

In conclusion, the benefits of using a Cortag tile cutter extend beyond simple tile cutting. These tools are designed to enhance your tiling work’s efficiency, precision, and aesthetic quality, all while offering a durable solution that withstands the test of time. Whether for professional use or a personal project, a Cortag tile cutter is an invaluable tool in achieving perfect results.

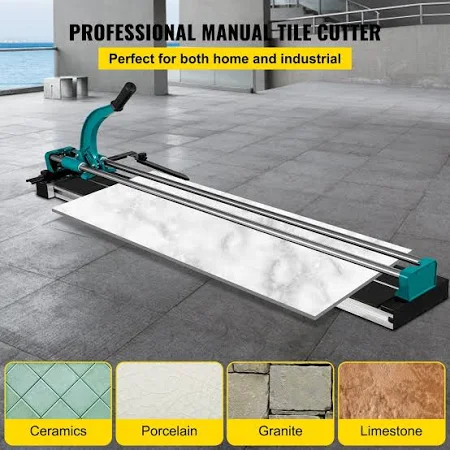

Large Format Tile Cutter

How to Choose the Right Cortag Tile Cutter

Selecting the appropriate Cortag tile cutter for your specific tiling project involves considering several factors. These range from the type of tiles you are working with to the scale of your project. Understanding the nuances of each model will ensure you choose a tile cutter that meets your needs efficiently and effectively.

Factors to Consider Based on Tile Type and Project Scale

When selecting a tile cutter, consider the following aspects:

- Tile Material: The hardness and size of the tiles are critical factors. For instance, porcelain tiles require a cutter with a diamond cutting wheel like the Cortag Mega 125, whereas ceramic tiles can be effectively cut with a standard ceramic cutting wheel, such as those on the Cortag Master Plus 125.

- Tile Size and Thickness: Larger tiles will require a tile cutter with extended support arms and a robust base to manage the additional weight and size, such as the Mega 125.

- Project Volume: For large-scale projects, a more durable and heavy-duty cutter is recommended to withstand continuous use without compromising on performance.

- Precision Required: Detailed mosaic or intricate cutting work might benefit from cutters with high precision guides and adjustable measuring options.

Comparisons of Different Cortag Models

To aid in the decision-making process, here’s a detailed comparison of the two popular Cortag models based on various project needs:

| Feature | Cortag Mega 125 | Cortag Master Plus 125 |

|---|---|---|

| Suitable for Tile Type | Porcelain, large ceramic tiles | Ceramic, glass tiles |

| Cutting Length | Up to 125 cm | Up to 125 cm |

| Cutting Wheel Type | 22 mm diamond tile cutter wheel | 22 mm ceramic tile cutting wheel |

| Base Material | Reinforced steel, suitable for heavy-duty use | Lighter steel, great for detailed work |

| Ideal Usage | Commercial projects, large-scale installations | Small to medium projects, decorative tiling |

| Additional Features | Extended support arms, robust construction | Ergonomic design, easy to maneuver |

Choosing Based on Specific Needs:

- For Large Scale and Heavy-Duty Projects:

- Cortag Mega 125: Ideal for commercial and large-scale residential projects where durability and the ability to handle large, hard tiles are paramount.

- For Precision and Detailed Work:

- Cortag Master Plus 125: Offers greater precision and is more suitable for projects involving delicate tiles like glass or detailed ceramic patterns.

Each Cortag tile cutter is designed with specific types of tiling projects in mind, ensuring that whether you are a professional tiler or a DIY enthusiast, there is a Cortag cutter that meets your project’s specific needs. By considering these factors and comparing the models, you can select a Cortag tile cutter that not only matches but enhances your tile cutting capabilities.

Small Tile Cutter

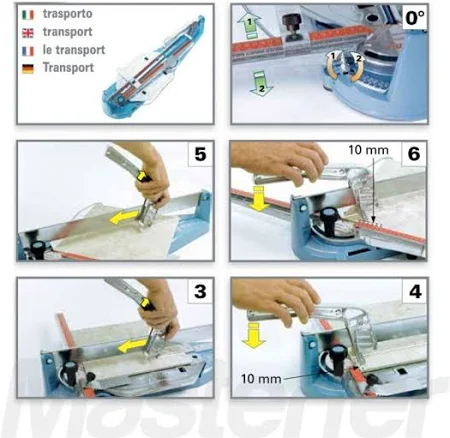

Step-by-Step Guide: How to Use a Cortag Tile Cutter

Using a Cortag tile cutter, such as the Cortag Mega 125 or the Cortag Master Plus 125, requires careful preparation and methodical execution to ensure clean, precise cuts. Here’s a comprehensive guide on how to effectively use these manual tile cutters.

Preparing Your Tiles and Workspace

Workspace Setup:

- Ensure your workspace is flat and stable. Use a sturdy table or a workbench that can support the weight of the tiles and the tile cutter.

- Clear the area of any debris or objects that could obstruct your movement or accuracy during cutting.

Tile Preparation:

- Clean the tiles thoroughly to remove any dust or particles that could affect the cutting process. Make sure the tiles are dry before starting.

- Mark the tile where you need to cut using a non-permanent marker. Use a straight edge to ensure the line is precise.

Detailed Steps for Using the Tile Cutter

Positioning the Tile:

- Place the tile on the Cortag tile cutter base, aligning it with the cutting wheel. Adjust the tile until the mark aligns perfectly with the guide on the cutter.

Scoring the Tile:

- Lower the cutting wheel onto the start of the mark.

- Apply even pressure and push or pull the lever (depending on the model) across the tile to score it in one continuous, smooth motion. This is crucial to ensure a clean break.

Snapping the Tile:

- Once the tile is scored, reposition it for snapping. Some Cortag models include a mobile breaker that helps apply even pressure along the score line.

- Press down firmly on the handle or breaker to snap the tile along the scored line.

Checking the Edge:

- After snapping, check the edges of the tile to ensure they are clean and smooth. If any adjustments are needed, a tile file can be used to gently smooth out rough edges.

Tips for Maintaining Precision and Safety

- Maintain Your Cutter: Regularly check and replace the cutting wheel on your Cortag tile cutter to ensure it remains sharp and effective. This is especially important for models like the Cortag Mega 125, which is often used for harder, thicker tiles.

- Wear Safety Gear: Always wear protective eyewear and gloves when cutting tiles to protect against flying debris and sharp edges.

- Secure Tiles: Use clamps if necessary to secure larger tiles to the cutting surface, ensuring they do not move during scoring.

- Single Stroke Scoring: Make sure to score the tile with a single, confident stroke. Multiple passes over the same line can weaken the precision of the cut and lead to uneven breaks.

- Clean After Use: Clean your tile cutter after each use to prevent the build-up of tile debris and dust, which can affect the cutter’s performance over time.

By following these steps, users of Cortag tile cutters can achieve professional-quality cuts with consistency and safety. Whether working with the robust Cortag Mega 125 or the precise Cortag Master Plus 125, proper technique and care will lead to successful tiling projects.

Brutus Tile Cutter

Common Mistakes to Avoid When Using a Tile Cutter

Using a tile cutter effectively requires not only skill and precision but also an awareness of common pitfalls that can affect the outcome of your tile cutting projects. Below, I outline some frequent user errors encountered with manual tile cutters like the Cortag Mega 125 and Cortag Master Plus 125, and how to correct these mistakes to ensure optimal results.

List of Frequent User Errors

Insufficient Pressure on the Scoring Wheel:

- A light hand while scoring can result in an incomplete or shallow score line, which may not break cleanly.

Multiple Passes Over the Same Score Line:

- Scoring the same line multiple times can lead to irregular breaks and diminish the accuracy of the cut.

Using a Dull Cutting Wheel:

- A worn-out cutting wheel can tear rather than cleanly score the glaze of the tile, leading to unsatisfactory breaks.

Misaligning the Tile:

- Incorrect alignment of the tile on the cutter base can cause the score to be off, leading to a cut that is not straight.

Failing to Secure the Tile:

- If the tile is not firmly placed or secured, it can move during scoring, resulting in uneven cuts.

Improper Tile Handling and Snapping:

- Applying uneven pressure during the snapping process can crack the tile or cause it to break in unintended ways.

How to Correct These Mistakes

Apply Consistent Pressure:

- Ensure that you apply steady and even pressure when using the scoring wheel. This will create a deep enough score line to facilitate a clean break.

One Firm Scoring Stroke:

- Always strive for one firm, continuous scoring stroke across the tile. This prevents weakening the tile’s structure with multiple score lines.

Regularly Replace the Cutting Wheel:

- Check and replace the cutting wheel regularly to maintain a sharp and effective scoring edge. Both the Cortag Mega 125 and Cortag Master Plus 125 have easily replaceable wheels that ensure continuous high performance.

Align Tiles Correctly:

- Use the built-in guides on the Cortag tile cutters to ensure your tile is perfectly aligned before scoring. Make adjustments as necessary to guarantee the score line is where it needs to be.

Secure the Tile:

- Clamp larger tiles or ensure they are firmly against the cutter’s surface to prevent movement during the scoring process.

Even Pressure During Snapping:

- Apply even pressure along the entire length of the score when snapping the tile. Some Cortag models come with a mobile breaker that helps distribute the force evenly.

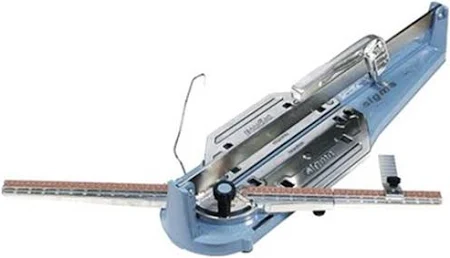

Sigma Tile Cutter 24 Inch

Maintenance and Care for Your Cortag Tile Cutter

Proper maintenance and care of your Cortag tile cutter are essential to ensure its longevity and optimal performance. Here’s a detailed guide on how to keep your tile cutter in top condition, including cleaning, storing, and replacing parts.

Cleaning and Storing the Cutter

Cleaning After Use:

- After completing your tile cutting tasks, it’s crucial to clean the cutter to remove any tile debris or dust. This can be done using a soft brush or a cloth to gently wipe down the surface.

- For more stubborn residues, especially after cutting porcelain tiles or when using wet saw tile cutters, a mild detergent and water can be used. Ensure that all components are dry before storing the cutter to prevent rust and corrosion.

Storing Your Tile Cutter:

- Store your tile cutter in a dry, clean environment. If you’re using large format models, like the 48 inch tile cutter, ensure that they are securely stored in a way that prevents any warping or damage to the guide rails.

- Smaller cutters, like the small tile cutter, should be stored in their original cases if available, or in a sturdy container that protects them from physical damage.

Replacing Parts and Where to Find Them

Common Parts That May Need Replacement:

- Cutting Wheels: The cutting wheels, especially on high-use tools like the Sigma tile cutter 24 inch or the Vevor tile cutter, can wear out and may need to be replaced periodically to maintain optimal cutting efficiency.

- Support Pads and Guide Rails: These are subject to wear and should be inspected regularly, especially if you use your cutter for large format tile cutting.

Where to Find Replacement Parts:

- Replacement parts can typically be found directly from the manufacturer or through specialized hardware stores. For specific items like a diamond blade for grinder or components for an electric tile cutter, it’s best to visit reputable online platforms like the links provided.

- For specialized items, such as parts for a Brutus tile cutter or a VCT tile cutter, ensure that the replacement parts match the exact model and specifications of your cutter.

Additional Maintenance Tips:

- Regularly check the alignment and condition of the cutting wheel and guide rails.

- Lubricate moving parts if specified by the manufacturer, particularly in models like the hand held tile cutter, to ensure smooth operation.

- Keep your manual handy for any specific maintenance guidelines or setup advice, especially if you’re undertaking more complex projects such as how to tile a shower or how to grout tile.

Proper care and regular maintenance of your Cortag tile cutter not only extend its life but also ensure it continues to perform at its best on every project, whether you’re trimming a backsplash in the kitchen or laying down new bathroom floor tiles.

Vevor Tile Cutter

Understanding Tile Cutter Challenges and Solutions

Why is my manual tile cutter breaking tiles?

- Incorrect Pressure: Applying too much force or uneven pressure can cause tiles to break. Ensure consistent, moderate pressure when scoring.

- Dull Blade: A worn-out blade on a manual tile cutter like the Cortag Mega 125 can cause improper scoring, leading to breakage. Replace blades regularly.

What is the hardest tile to cut?

- Porcelain tiles are notably hard to cut due to their density and hardness. They require a sharp, durable cutting wheel, such as those on high-end tile cutters like the Cortag Master Plus 125.

Is it better to use a tile cutter or wet saw?

- Tile Cutter: Best for straight, clean cuts on ceramic and some porcelain tiles. Quieter and more portable.

- Wet Saw: Preferred for cutting a variety of tile types, especially porcelain and stone, and for making intricate cuts like angles and curves.

Why are porcelain tiles so hard to cut?

- Density and Composition: Porcelain tiles are fired at higher temperatures making them denser and harder, which requires more robust tools for effective cutting.

Do you need a special tile cutter for porcelain tiles?

- Yes. Porcelain tiles typically require a tile cutter with a diamond cutting wheel, like the Cortag Mega 125, which is specifically designed to handle tougher materials.

Why do my porcelain tiles keep cracking when I cut them?

- Blade Quality: Ensure you are using a high-quality diamond blade.

- Scoring Depth: Incorrect scoring depth can lead to cracks. Adjust the blade to score appropriately deep without over-penetrating.

Should you wet tiles before cutting?

- No, for manual tile cutters. Wetting is primarily for wet saws to reduce dust and cool the blade.

How to stop porcelain tiles from chipping when cutting?

- Proper Tool: Use a sharp diamond blade.

- Correct Technique: Ensure the tile is fully supported and use a gentle, consistent pressure when scoring.

What tile will never go out of style?

- Ceramic and Subway Tiles: Both are timeless choices that remain popular due to their versatility and aesthetic appeal.

Do you cut porcelain tile upside down?

- No, always cut with the finished side up to ensure the most visible part of the tile has the cleanest edge.

What is the best tool to cut porcelain tile?

- Wet Saw with a diamond blade is generally considered the best tool for cutting tough porcelain tiles.

Do you use tile cutter in front or back?

- Front: Align the tile face up in the cutter to check the score line accurately.

What is an alternative to a tile saw?

- Tile Nipper: Useful for small, awkward cuts where a tile saw isn’t practical. Ideal for cutting odd shapes but not straight lines.

Do you put water in a tile cutter?

- No, not in manual tile cutters like the Cortag models. Water is used in wet saws for cooling and dust reduction.

Is there a trick to cutting porcelain tile?

- Multiple Light Scores: Instead of one deep score, multiple light scores can help prevent chipping and make the break cleaner.

Does Rubi tile cutter cut porcelain?

- Yes, Rubi tile cutters are equipped with high-quality blades suitable for cutting porcelain when the appropriate blade is used.

What does a tile nipper do?

- Nibbles Away Tile Edges: Useful for making circular cuts or small notches in tiles, but not suitable for long, straight cuts.

Why do my porcelain tiles break when cutting?

- Inadequate Support: Ensure the entire tile is well-supported and flat on the cutter base.

- Scoring Force: Too much force can fracture the tile. Use a consistent, moderate pressure.

What to look for when buying a tile cutter?

- Cutting Capacity: Match the cutter size with the largest tile you plan to cut.

- Blade Quality: Look for cutters with high-grade blades, such as diamond-tipped ones for porcelain.

Can I score and snap porcelain tile?

- Yes, but it requires a high-quality manual cutter with a suitable scoring wheel, like the Cortag tile cutters designed for porcelain.

How do you hide a hairline crack in porcelain tile?

- Color-Matched Caulk: Apply caulk that matches the tile color to effectively conceal small cracks.

Can you cut porcelain tiles with a normal tile cutter?

- Depends on the Tile Cutter: Standard tile cutters might work for thinner porcelain tiles, but a cutter designed for porcelain is recommended for the best results.

Can you polish porcelain tile edges?

- Yes, with the right tools such as a hand-held stone polisher or diamond polishing pads to smooth and finish the edges after cutting.

Each of these answers highlights the importance of using the correct tools and techniques, such as those offered by Cortag tile cutters, to ensure clean, precise cuts and extend the lifespan of both your tools and tiles.