MK tile saws have set the standard in the industry for their durability, precision, and build quality. Renowned for their robust engineering, MK tile saws range from compact models like the MK-170 Tile Saw to larger, more advanced units such as the MK-212 Tile Saw. Each saw is designed to cater to specific needs, whether for DIY enthusiasts or professional contractors.

Importance of Using the Right Tile Saw

Choosing the correct tile saw is crucial for achieving clean, precise cuts and ensuring safety during tile cutting projects. The use of a specialized tool like an MK tile saw ensures that whether you are working with ceramic, porcelain, or stone tiles, the outcome is consistently excellent.

Highlighted Models and Their Uses

- MK-101 Tile Saw: Ideal for cutting floor tiles and wall tiles with its high torque motor, ensuring smooth cutting of even the toughest materials.

- MK Diamond Tile Saw: A preferred choice for professionals needing a reliable saw for large-scale projects and varied tile materials.

- MK Wet Tile Saws: These saws use water to cool the diamond blade, allowing for dust-free and heat-reduced cutting, perfect for prolonged use.

Choosing the Right MK Tile Saw

When selecting an MK tile saw, consider the following factors to match the saw with your project requirements:

- Tile Type: Different tiles require specific blade types. MK diamond wet saws are excellent for dense tiles like porcelain and stone.

- Project Size: Larger projects might need saws with extensive cutting lengths and more power, like the MK-212 Tile Saw.

- Portability: For jobs requiring mobility, compact saws such as the MK-170 or the Mini Wet Tile Saw are ideal.

Products

Types of MK Tile Saws

Overview of Different Models

MK Diamond offers a wide array of tile saws, each engineered to meet specific needs in the realm of tile cutting. These saws are categorized mainly into wet saws, dry saws, and handheld saws, with each category featuring models that vary in power, size, and cutting capabilities. Let’s explore these types to help you choose the right saw for your project.

MK Wet Tile Saws

Wet tile saws are preferred for their precision and ability to cut at high speeds without overheating the blade or the tile. MK Diamond’s wet saw lineup includes:

- MK-101 Wet Tile Saw: Known for its durability and large cutting length, ideal for complex cutting tasks like mitering and beveling.

- MK-370EXP Wet Tile Saw: Offers a lightweight design with a powerful motor, suitable for projects requiring mobility and ease of use.

- MK-212 Series: These are robust saws designed for cutting large tiles and stone materials, equipped with features like plunge cut capability and tilting head.

Key Features:

- Water pump and high-capacity water pans for optimal blade cooling.

- Variable height cutting heads to accommodate different tile thicknesses.

- Sliding tables and guide systems for precise straight and miter cuts.

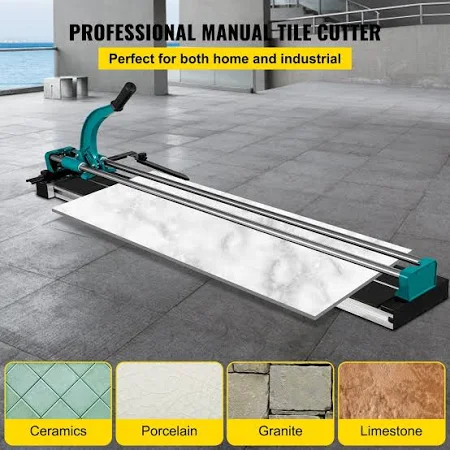

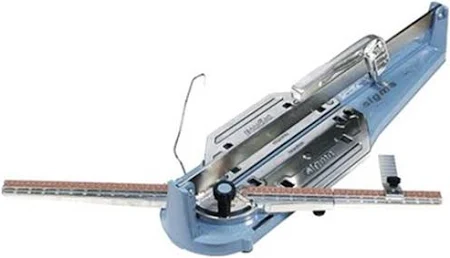

MK Dry Tile Saws

Dry tile saws are designed for jobs where water use is impractical. They rely on dust extraction systems to manage debris and are less common in the MK Diamond product range. However, they provide an effective solution for quick jobs or outdoor settings where water setup is challenging.

MK Handheld Tile Saws

For ultimate flexibility and portability, MK handheld tile saws like the MK-170 and MK Diamond Saw TG are ideal. These are perfect for touch-ups, irregular cuts, or where space is limited.

- MK-170 Tile Saw: Compact and easy to transport, this model is excellent for small renovations and repairs at home.

- MK Diamond Saw TG: Offers a grip handle and lightweight design, making it suitable for cutting curved lines and reaching tight spots.

Advantages of Handheld Saws:

- Enhanced maneuverability.

- Simple setup and minimal maintenance.

- Capability to cut right in place without needing to move heavy tiles.

Choosing the Right MK Tile Saw

To select the most suitable MK tile saw, consider the tile type and size you frequently work with, the conditions of your typical work site, and your portability needs. Here’s a quick comparison to aid your decision:

| Saw Type | Best For | Features |

|---|---|---|

| MK Wet Tile Saws | Large projects, frequent use, diverse tile materials | Water-cooled, large cutting lengths, precise |

| MK Dry Tile Saws | Quick, outdoor cuts without water setup | Dust management, less preparation required |

| MK Handheld Saws | Small projects, tight spaces, speciality cuts | Portable, easy to maneuver, no setup required |

Each type of MK tile saw is designed with specific uses in mind, ensuring that no matter your project type or size, there is an MK saw that can meet your needs with precision and efficiency. Whether you choose a wet, dry, or handheld model, MK Diamond products represent quality and reliability in tile cutting technology.

Ryobi Tile Cutter

Specific Models Highlight: MK Tile Saws

MK-101 Tile Saw

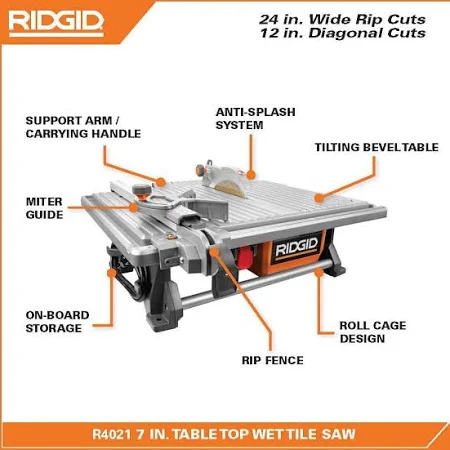

The MK-101 Tile Saw is a staple for professionals requiring reliability and precision. Designed for cutting large tiles, this model features a powerful high-torque motor and a built-in water distribution system that minimizes dust and debris.

- Power and Performance: 1.5 HP motor suitable for heavy-duty jobs.

- Cutting Capacity: Handles tiles up to 24 inches in length and 18 inches diagonally.

- Durability: Heavy-duty steel frame and corrosion-resistant materials.

MK-370EXP Tile Saw

The MK-370EXP Tile Saw offers a lightweight solution without compromising on power, perfect for jobs requiring frequent transportation of the saw.

- Motor: 1.25 HP with a 6,000 RPM blade speed for quick and clean cuts.

- Portability: Weighs only 33 pounds, making it easy to move and set up.

- Versatile Cutting: Tilting head allows for 45-degree miter cuts.

MK-212 Tile Saw

The MK-212 Tile Saw is tailored for cutting large natural stone tiles, providing precision and the ability to perform plunge cuts and mitering.

- Powerful Motor: 2 HP motor for cutting the toughest materials.

- Large Format Cutting: Designed for slabs up to 36 inches in length.

- Plunge and Miter Capabilities: Offers a variety of cuts without additional setups.

MK-170 Tile Saw

For small-scale projects or tight spaces, the MK-170 Tile Saw is the go-to. It is ideal for DIYers or professionals needing a compact yet effective tool.

- Motor and Blade: 0.5 HP motor with a 7-inch diamond blade.

- Compact Design: Small footprint and easy setup for residential use.

- Water Reservoir: Built-in water reservoir eliminates the need for a water hookup.

Comparison Table of Specific MK Tile Saw Models

| Model | Motor Power | Blade Size | Cutting Capacity | Special Features |

|---|---|---|---|---|

| MK-101 Tile Saw | 1.5 HP | 10″ | 24″ length, 18″ diagonal | High-torque, built-in water system |

| MK-370EXP Tile Saw | 1.25 HP | 7″ | 18″ length | Lightweight, tilting head for miters |

| MK-212 Tile Saw | 2 HP | 10″ | 36″ length | Plunge cuts, designed for large tiles |

| MK-170 Tile Saw | 0.5 HP | 7″ | 12″ length | Compact, built-in reservoir |

Each of these models caters to different needs, from heavy-duty professional use to more casual or compact applications. The MK-101 and MK-212 stand out for professional large-scale projects, while the MK-370EXP and MK-170 are more suited for smaller projects or those requiring portability.

For more details on purchasing these models, consider visiting:

- MK Diamond 7″ 1-1/4 HP Tile Saw – Model 159943

- M.K. Diamond MK-145 Table Top Tile Saw

- Makita 4100NHX1 Masonry Saw

- Makita CC301DSMJ Tile Cutter

This detailed comparison and the links provided should assist in making an informed decision based on specific cutting requirements and project needs.

Glass Tile Cutter

Key Features of MK Tile Saws

Cutting Capacity and Versatility

MK tile saws are renowned for their exceptional cutting capacity and versatility, making them suitable for a wide range of materials and project sizes.

- Wide Range of Cuts: From straight, clean cuts to bevels and miters, MK tile saws handle everything from porcelain to marble.

- Adjustable Cutting Heights: Many models feature adjustable cutting heads to manage different tile thicknesses without compromising precision.

- Examples:

- MK-101 Tile Saw: Cuts up to 24 inches in length and 18 inches diagonally, suitable for both small and large tile projects.

- MK-370EXP Tile Saw: Offers a lightweight yet powerful option for varied cutting tasks including miter cuts up to 45 degrees.

Power and Motor Specifications

The power behind MK tile saws ensures efficient and consistent performance, critical for both professional and home use.

- Robust Motors: Ranging from 0.5 HP in smaller models to over 2 HP in professional-grade saws, ensuring smooth and quick cuts through tough materials.

- High Torque: MK Diamond’s high-torque motors provide the necessary power to prevent bogging down during heavy-duty cutting tasks.

Durability and Build Quality

Durability is a cornerstone of MK Diamond products, with each saw built to withstand rigorous use and harsh job site conditions.

- Rugged Construction: Heavy-duty metal components and corrosion-resistant materials extend the life of the saws under frequent or industrial use.

- Sealed Bearings and Commercial-Grade Components: These features ensure long-term reliability and minimal maintenance.

Safety Features

Safety is paramount when designing powerful cutting tools. MK tile saws incorporate several features to ensure user safety without compromising performance.

- Built-in Water Pumps and Pans: Reduce dust and debris, crucial for maintaining visibility and preventing respiratory issues.

- Blade Guards and Locks: Protect users from blade contact, while thermal overload protection prevents motor damage.

- Slip-Resistant Feet and Stability Features: Keep the saw steady during operation, reducing the risk of accidents.

Table: Comparison of Key Features Across Select Models

| Model | Motor Power | Cutting Capacity | Safety Features | Durability Highlights |

|---|---|---|---|---|

| MK-101 Tile Saw | 1.5 HP | 24″ length, 18″ diagonal | Blade guard, overload protection | Heavy-duty steel, corrosion-resistant design |

| MK-370EXP Tile Saw | 1.25 HP | 18″ length | Thermal overload protector, blade guard | Compact frame, durable components |

| MK-212 Tile Saw | 2 HP | 36″ length | Plunge cut capability, water pump | Sealed bearings, built to handle large tiles |

| MK-170 Tile Saw | 0.5 HP | 12″ length | Water reservoir, blade guard | High-impact composite material, lightweight |

For detailed descriptions of each model and to find the right tool for your tile cutting needs, click here for more information on MK Wet Tile Saws.

Cortag Tile Cutter

Choosing the Right MK Tile Saw

Selecting the appropriate MK tile saw involves several considerations to ensure you match the tool’s capabilities with your project’s specific requirements.

Factors to Consider

Type of Tile Material

Different materials require different types of saws and blades to ensure clean cuts without damaging the tile.

- Porcelain and Ceramic: Harder materials like porcelain often require a more robust tile saw with a diamond blade, such as the MK Diamond Tile Saw.

- Stone: Materials like marble or granite will benefit from a powerful wet saw like the MK-212 Tile Saw, which can handle larger, thicker slabs.

Size of Tile Project

The size and scope of your project will determine the size and type of tile saw needed.

- Small Projects: For smaller projects or DIY tasks, a smaller, more portable saw like the MK-170 Tile Saw or the MK-145 Table Top Tile Saw might be sufficient.

- Large Projects: For large scale projects involving heavy or large format tiles, consider larger models like the MK-212 Tile Saw or the MK-101 Tile Saw, which have extended cutting lengths and more powerful motors.

Frequency of Use

How often you use the tile saw can influence the type of saw you should purchase, particularly concerning durability and ease of maintenance.

- Occasional Use: For those using a tile saw occasionally, a more compact and less expensive model like the MK-170 may be appropriate.

- Regular to Heavy Use: For professionals or frequent users, investing in a higher-end model with enhanced durability and features, such as the MK-101 or MK-370EXP, is advisable to withstand the rigors of frequent use.

Recommended MK Tile Saws for Various Needs

- Best for Versatility: The MK-370EXP Tile Saw offers a good balance of portability, power, and cutting capacity, suitable for many different tile types and project sizes.

- Best for Large Projects: The MK-212 Series Tile Saw stands out for its ability to manage large format tiles and stone, making it ideal for substantial commercial projects.

- Best for Frequent Use: The MK-101 Tile Saw, known for its durability and high-capacity cutting capabilities, is perfect for professionals who need a reliable saw for daily use.

For more details on purchasing and additional product specifications, consider visiting the linked Wet Saw Tile Cutters.

VCT Tile Cutter

Comparison of Top Models: MK-101 vs. MK-370EXP and Wet vs. Dry Saws

MK-101 vs. MK-370EXP

The MK-101 and MK-370EXP are two of MK Diamond’s most popular tile saw models, each serving different user needs based on project scale and frequency of use.

MK-101 Tile Saw

- Motor Power: 1.5 HP, offering robust performance for heavy-duty tasks.

- Blade Capacity: Accommodates a 10-inch blade, allowing deeper cuts and handling of thicker tiles.

- Cutting Length: Up to 24 inches, ideal for large tiles and pavers.

- Features: Includes a built-in water pump and cutting table, which is perfect for prolonged and frequent use in professional settings.

MK-370EXP Tile Saw

- Motor Power: 1.25 HP, slightly less powerful but still capable for most tiles.

- Blade Capacity: Uses a 7-inch blade, suitable for standard tile sizes.

- Cutting Length: Up to 18 inches, suitable for smaller or medium-sized projects.

- Features: Lightweight and portable with a hinged blade guard for easy blade changes and maintenance.

Comparison Table

| Feature | MK-101 Tile Saw | MK-370EXP Tile Saw |

|---|---|---|

| Motor Power | 1.5 HP | 1.25 HP |

| Blade Size | 10 inches | 7 inches |

| Cutting Capacity | Up to 24 inches length | Up to 18 inches length |

| Ideal Use | Large scale, frequent use in professional jobs | Smaller projects, excellent for DIYers |

| Portability | Less portable, heavier | Highly portable, lighter design |

| Additional Features | Large water reservoir, versatile cutting table | Easy blade change, tilt feature for bevels |

For professional large-scale projects, the MK-101 Tile Saw is preferable, while the MK-370EXP is better suited for home renovations or smaller tasks. Learn more about the MK-101 at Wet Saw Tile Cutters.

Wet vs. Dry Saws

Choosing between wet and dry tile saws depends largely on the specific requirements of your tiling project, including location, material, and desired finish.

Wet Saws

- Use Case: Ideal for cutting dense materials like porcelain, granite, and other natural stones. Water cools the blade and reduces dust for cleaner cuts.

- Advantages: Provides better control over cutting, reducing the likelihood of chipping or breaking delicate tiles. Essential for large projects or continuous work.

- Example: The MK-101 is a top choice for those needing a reliable wet saw for complex, professional jobs.

Dry Saws

- Use Case: Best for quick, smaller jobs or where water use is impractical. Often used for trimming or dry installations.

- Advantages: More portable and quicker to set up than wet saws, without the need for water and extensive cleanup.

- Safety Consideration: Produces more dust, so adequate ventilation and dust masks are necessary.

Comparison Table

| Feature | Wet Saws | Dry Saws |

|---|---|---|

| Material Suitability | Porcelain, granite, large format tiles | Ceramic, thin tiles, quick trims |

| Cutting Environment | Controlled, needs water setup, minimal dust | Any environment, more dust |

| Result Quality | Smooth, precise cuts, less tile damage | Faster, less precise, potential for more chips |

| Setup and Cleanup | Requires preparation and cleanup, less portable | Quick setup, highly portable |

For detailed guidance on choosing the best tool for your tile cutting needs, consider visiting: Best Tile Cutter For Porcelain and How To Cut Tile.

Hand Held Tile Cutter

Accessories and Replacement Parts for MK Tile Saws

Ensuring your MK tile saw operates at its best requires the right accessories and timely replacement of parts. Here’s a detailed overview of essential accessories and components to keep your saw in top condition.

Blades

Choosing the right blade is crucial for achieving clean and precise cuts, minimizing material waste, and extending the life of your saw.

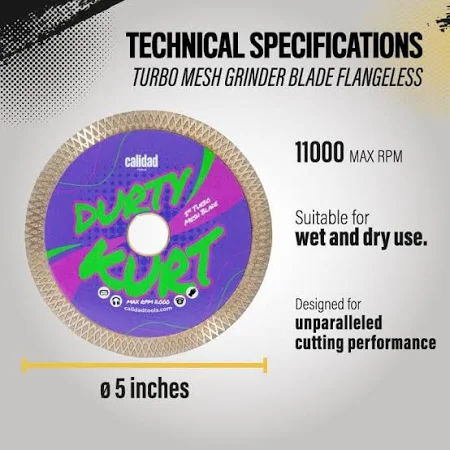

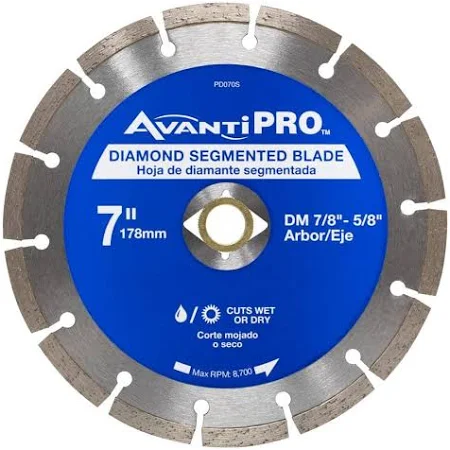

Diamond Blades

- Purpose: Designed for cutting through tough materials like ceramic, porcelain, and natural stone.

- Features: High diamond concentration for increased cutting speed and longevity.

- Product Highlight: MK Diamond’s diamond blades offer precision cutting with minimal chipping.

Wet Cutting Blades

- Purpose: Specifically used with wet tile saws to provide clean cuts while keeping the blade cool.

- Features: Continuous rim design to ensure smooth cuts and to prevent overheating.

- Product Highlight: Ideal for projects that require extensive cutting, such as tiling showers or large flooring areas.

Other Accessories

Maintaining and enhancing the functionality of your MK tile saw can be achieved with several additional accessories.

Stands

- Utility: Provides a stable and ergonomic working height, improving comfort and efficiency during long cutting sessions.

- Available Options: Universal stands that fit various MK tile saw models, including collapsible designs for easy transport and storage.

Water Pumps

- Purpose: Essential for wet saws, these pumps circulate water to the blade, crucial for dust reduction and blade longevity.

- Compatibility: Ensure the pump matches the flow rate and power requirements of your saw model.

Guides and Tables

- Functionality: Improve cutting accuracy with straight and angle cuts.

- Variety: From simple straight cut guides to complex miter cutting tables, these accessories help in achieving precise measurements and cuts.

Table: Recommended Accessories for MK Tile Saws

| Accessory Type | Description | Benefits | Recommended for Model(s) |

|---|---|---|---|

| Diamond Blades | High diamond concentration for tough materials | Precise cuts, long lifespan | All MK wet and dry tile saws |

| Wet Cutting Blades | Continuous rim for smooth cuts in wet conditions | Clean cuts, prevents overheating | MK-101, MK-370EXP, other wet saws |

| Stands | Sturdy, often portable support for the saw | Ergonomic operation, enhances stability | Compatible with various models |

| Water Pumps | Circulates water to the blade | Reduces dust, cools blade | Required for all MK wet saw models |

| Guides and Tables | Accessories for precise measurements and cuts | Increases cutting accuracy, versatile setups | Especially useful for MK-212, MK-101 |

For more information on where to purchase these accessories, or to find specific parts like the Diamond Blade for Grinder, visit Diamond Blade For Grinder.

Ensuring Peak Performance

Regular maintenance and the use of genuine MK accessories ensure your tile saw functions effectively for each project. Whether you’re cutting tiles for a small bathroom update or handling a large commercial installation, equipping your MK tile saw with the right accessories and replacement parts is key to achieving professional-grade results consistently.

48 Inch Tile Cutter

Maintenance Tips for MK Tile Saws

Proper maintenance is crucial for ensuring your MK tile saw operates efficiently and lasts through many projects. Here’s how to keep your MK tile saw in top condition through routine cleaning, blade replacement, and troubleshooting common issues.

Routine Cleaning and Upkeep

Keeping your MK tile saw clean is essential for performance and longevity. Here’s how to maintain it:

- Daily Cleaning: After each use, clean the machine of any tile debris and sludge. A simple wipe-down with a damp cloth can prevent buildup that affects performance.

- Water System Maintenance: Regularly check and clean the water pump and reservoir to ensure efficient cooling and lubrication of the blade. This prevents overheating and minimizes wear.

- Check Moving Parts: Lubricate all moving parts periodically to ensure smooth operation. Focus on the sliding table, cutting head, and blade shaft.

Blade Replacement

Blades must be replaced periodically to ensure clean and precise cuts. Here’s how to handle blade replacements on your MK tile saw:

- Inspect Blades Regularly: Look for signs of wear or damage such as chips or uneven segments. A worn blade can result in poor cut quality and increased strain on the saw.

- Choose the Right Blade: Use MK Diamond blades or compatible high-quality diamond blades designed for the specific materials you are cutting.

- Replacing the Blade:

- Disconnect the saw from power.

- Remove the blade guard.

- Loosen the nut holding the blade using the wrench provided with your saw.

- Replace the blade and securely tighten the nut.

Troubleshooting Common Issues

Here are solutions to some common issues you might encounter with your MK tile saw:

- Reduced Cutting Efficiency: If your saw is not cutting as efficiently, check if the blade is dull or damaged. Replace the blade if necessary. Also, ensure the water pump is functioning correctly to provide adequate water flow.

- Unusual Noise or Vibration: This could be due to a loose blade or component. Check and tighten any loose parts. Also, ensure the saw is on a stable and level surface.

- Overheating: Make sure the water system is working correctly. An inadequate water supply can cause the blade and motor to overheat. Clean the water pump and check hoses for blockages.

Maintenance Table for Quick Reference

| Maintenance Task | Frequency | Instructions |

|---|---|---|

| Cleaning | After each use | Clean debris and damp wipe. Check water system. |

| Blade Inspection | Monthly/As needed | Check for wear or damage. Replace if necessary. |

| Lubrication of Moving Parts | Every 6 months | Apply lubricant to moving components. |

| Water Pump Maintenance | Every 6 months | Clean and ensure it is free of blockages. |

| Check for Loose Components | Every 3 months | Tighten any loose nuts, bolts, and other components. |

Proper maintenance not only extends the life of your MK tile saw but also ensures it operates safely and effectively. Whether you’re a professional contractor or a DIY enthusiast, following these guidelines will help maintain your saw’s performance and reliability. For more specific maintenance information or to purchase replacement parts, visit MK Diamond’s official website or contact their support team.

Diamond Blade For Grinder

FAQs

Company and Product Information

Is MK Diamond still in business in the USA?

Yes, MK Diamond Products, Inc. remains active and continues to serve as a prominent manufacturer of professional tools for cutting, coring, and polishing in the United States. Their products are widely recognized in the construction and renovation industries for their quality and reliability.

Where are MK tile saws made?

MK Diamond products are primarily manufactured in the United States, adhering to high standards of quality and engineering, ensuring reliability and durability in their tile saws and other products.

Who is the owner of MK Diamond?

MK Diamond is a family-owned business, but specific ownership details are typically kept private. The company prides itself on maintaining its longstanding reputation for quality and customer service in the industry.

What happened to MK Diamond products?

MK Diamond continues to thrive, consistently updating and expanding their product line to include the latest advancements in cutting technology and meeting the ever-evolving needs of both professionals and DIY enthusiasts.

Product Specifications and Usage

What size blade is a MK370?

The MK-370EXP Tile Saw uses a 7-inch diamond blade, suitable for handling various cutting tasks with precision and efficiency.

Do you cut ceramic tile face up or down?

Ceramic tile should generally be cut face up to minimize chipping and to ensure the finished side is as clean and precise as possible.

What is the hardest tile to cut?

Porcelain tile is considered one of the hardest materials to cut due to its density and the need for a diamond blade to achieve a clean cut without causing damage.

How do you keep ceramic tiles from chipping when cutting?

To prevent chipping when cutting ceramic tiles:

- Ensure the blade is sharp and appropriate for the type of tile.

- Use a wet saw to keep the blade cool and reduce friction.

- Apply a slow and steady feed rate to minimize pressure on the tile edges.

Can a tile saw be used to cut rocks?

While not recommended for large or very hard rocks, a tile saw can cut softer or smaller rocks when equipped with the appropriate blade, such as a diamond blade designed for stone cutting.

Where are MK blades made?

MK blades are manufactured in the United States, ensuring they meet rigorous standards for quality and performance.

Miscellaneous

Are silky saws made in Japan?

Yes, Silky saws are made in Japan. They are well-regarded for their precision and durability, often used in gardening and outdoor activities.

What blade size is legal?

Blade size legality typically refers to knives rather than saw blades, and it varies by jurisdiction. For tools like tile saws, there are no legal restrictions on blade size, but safety guidelines should always be followed.

What is a 40t blade used for?

A 40-tooth (40t) blade is commonly used on circular saws for making smoother cuts in wood. It strikes a balance between cutting speed and finish quality.

How long is a LT70 blade?

The LT70 refers to a sawmill from Wood-Mizer, and the blade length can vary based on the model configuration. Typically, these blades range around 158 inches long, but it is best to consult specific model documentation for accuracy.

Business Information Queries

Who is the owner of 7 Diamonds, MK Group, and the CEO of Diamond company?

- 7 Diamonds: Typically a privately held company; ownership details might not be public.

- MK Group: Ownership would depend on the specific MK Group being referred to, as many companies might use this name globally.

- CEO of Diamond Company: This could refer to numerous businesses in the gemstone industry; specifics would depend on the actual company in question.