Ceiling tile cutters are specialized tools designed to precisely cut ceiling tiles, an essential task in both residential and commercial construction. These tools vary widely in terms of design, capability, and price, making it vital to select the right ceiling tile cutter for your specific project needs. Whether you’re replacing old ceiling tiles or installing a new ceiling, having the right cutter can make the job easier, faster, and more efficient.

Types of Ceiling Tile Cutters

There are several types of ceiling tile cutters available on the market, each suited for different types of tiles and cutting requirements:

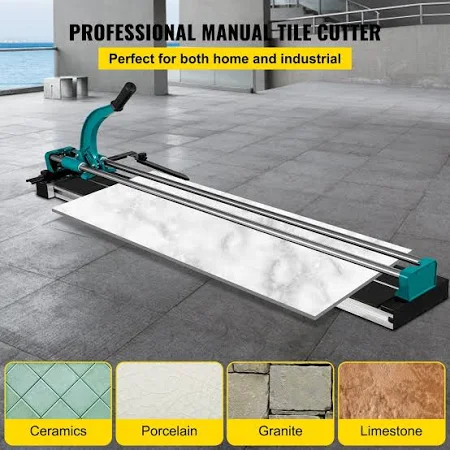

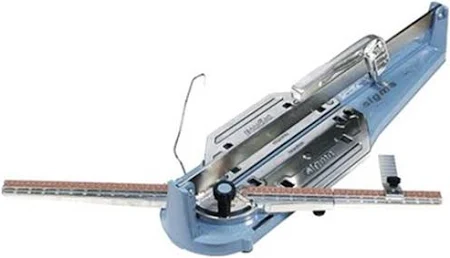

- Manual Tile Cutters: Ideal for quick, straightforward cuts on standard 2 by 4 ceiling tiles. Brands like Sigma 2B3 25 inch Tile Cutter and Muzata Tile Cutter 48 inch offer robust solutions for manual cutting.

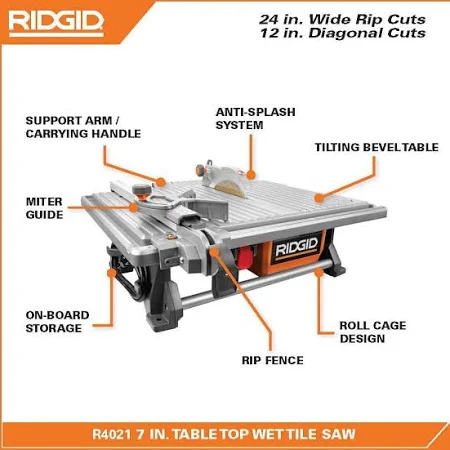

- Electric Tile Cutters: These provide precision and power, suitable for intensive use or thicker, tougher materials. VEVOR Wet Tile Saw 7-inch and DeWalt DWC860W Wet/Dry Tile Saw are popular choices for those needing electric options.

- Specialty Cutters: Tools like the Sigma Series 4 NEX Push Tile Cutter and Rubi Hit N 48″ Professional Tile Cutter are designed for specific tasks such as making reveal cuts or cutting oversized tiles.

Choosing the Right Ceiling Tile Cutter

When selecting a ceiling tile cutter, consider the following features to find the best match for your needs:

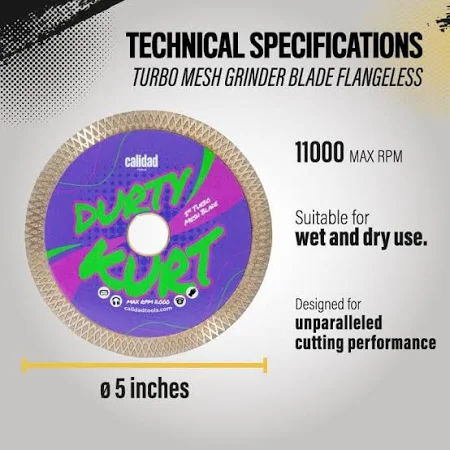

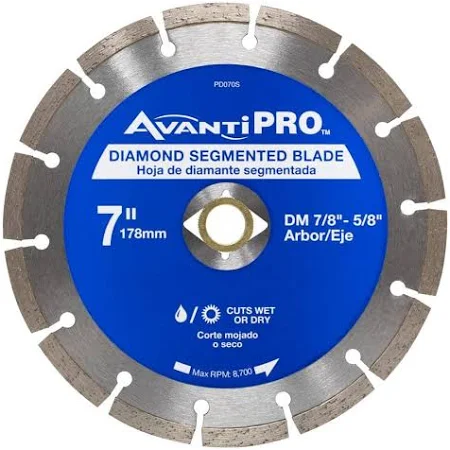

- Blade Quality: Look for cutters with durable blades, capable of making clean cuts without damaging the tiles. Calidad Turbo Diamond Saw Blades and Diablo DMADS1000 10″ Diamond Discs for Masonry are excellent for their longevity and precision.

- Cutting Capacity: Ensure the cutter can handle the size of the tiles you plan to cut. The VEVOR Manual Tile Cutter Cutting Machine with Infrared is known for its ability to cut large format tiles with precision.

- Ergonomics and Safety: Choose cutters that are easy to handle and safe to operate. Features like non-slip handles and built-in safety locks can be found in models like Quinn Heavy Duty Tile Cutter.

Popular Ceiling Tile Cutter Reviews

- Sigma 2B3 25 inch Tile Cutter – Ideal for precise manual cutting.

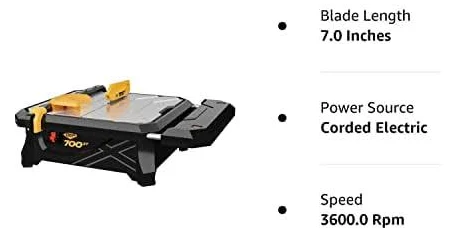

- VEVOR Wet Tile Saw 7-inch – Perfect for electric cutting with high power output.

- Rubi Hit N 48″ Professional Tile Cutter – Best for professional, large-scale projects.

- Whizmax Manual Tile Cutter – A reliable choice for general use.

- DeWalt DWC860W Wet/Dry Tile Saw – Versatile for both wet and dry cutting environments.

Dimension Table

Here is a dimension table for some of the popular ceiling tile cutters mentioned:

| Tile Cutter Model | Cutting Length (inches) | Max Tile Thickness (mm) | Weight (lbs) |

|---|---|---|---|

| Sigma 2B3 25 inch Tile Cutter | 25 | 15 | 22 |

| VEVOR Wet Tile Saw 7-inch | 18 | 30 | 26 |

| Rubi Hit N 48″ Professional Cutter | 48 | 20 | 47 |

| Whizmax Manual Tile Cutter | 48 | 12 | 19 |

| DeWalt DWC860W Wet/Dry Tile Saw | 20 | 30 | 29 |

Further Reading and Resources

- How to Cut Tile – Detailed guide on various cutting techniques.

- Electric Tile Cutter – Explore different electric tile cutters.

- Top 10 Best Tile Cutters – List of the best tile cutters available on the market.

Importance of Choosing the Right Tool for Cutting Ceiling Tiles

Selecting the appropriate ceiling tile cutter is crucial for achieving optimal results in both installation and aesthetic appeal. The right tool not only ensures a precise and clean cut but also enhances the efficiency and safety of the cutting process. Here’s why choosing the correct ceiling tile cutter is vital:

Precision and Cleanliness

- Accurate Cuts: Using the correct cutter, like the Sigma Series 4 NEX Push Tile Cutter, ensures that each tile fits perfectly within the ceiling grid, reducing waste and rework.

- Clean Edges: Cutters like the VEVOR Manual Tile Cutter with Infrared offer precision that prevents chipping and cracking, maintaining the integrity and appearance of the tile.

Efficiency and Speed

- Time-Saving: Tools designed for specific tile sizes, such as the 48 Inch VEVOR Tile Cutter, allow for quick setup and execution, significantly speeding up the installation process.

- Ease of Use: Ergonomically designed models, like the Quinn Heavy Duty Tile Cutter, reduce user fatigue, making it easier to handle large projects.

Versatility and Adaptability

- Multiple Tile Types: A versatile cutter, such as the Rubi Hit N 48″ Professional Tile Cutter, can handle various tile materials and thicknesses, from acoustic ceiling tiles to fiberglass tiles.

- Adjustable Settings: Cutters with adjustable blades or cutting guides, like the TILER 48 Inch Manual Tile Cutter, adapt to different tile depths and sizes, providing flexibility across projects.

Safety

- Reduced Risk of Injury: Proper tools minimize the risk of accidents. Cutters with built-in safety features, like blade guards found in the DeWalt DWC860W Wet/Dry Tile Saw, ensure safer operation.

- Enhanced Control: Sturdy, well-designed cutters offer better control over the cutting process, preventing slips and mis-cuts.

Economic Considerations

- Cost-Effective: Choosing the right tool reduces the need for replacements due to improper cuts. Tools like the Sigma 2B3 25 inch Tile Cutter are known for their durability and long-term performance.

- Less Material Waste: Accurate cuts mean less material is wasted, which is crucial in projects using expensive materials like beveled tegular ceiling tiles.

Product Recommendations and Links

Here are some recommended products that align with the needs highlighted in this section:

- Sigma Series 4 NEX Push Tile Cutter: Ideal for precision and clean cuts.

- VEVOR Manual Tile Cutter with Infrared: Enhances cutting accuracy for delicate tiles.

- Rubi Hit N 48″ Professional Tile Cutter: Versatile for multiple tile types.

- Quinn Heavy Duty Tile Cutter: Ergonomic design for large scale projects.

- DeWalt DWC860W Wet/Dry Tile Saw: Safe and sturdy for various cutting environments.

Dimension Table for Recommended Ceiling Tile Cutters

| Model | Max Cut Length (inches) | Max Tile Thickness (mm) | Weight (lbs) |

|---|---|---|---|

| Sigma Series 4 NEX Push Tile Cutter | 34 | 19 | 24 |

| VEVOR Manual Tile Cutter with Infrared | 48 | 16 | 21 |

| Rubi Hit N 48″ Professional Tile Cutter | 48 | 20 | 30 |

| Quinn Heavy Duty Tile Cutter | 20 | 12 | 18 |

| DeWalt DWC860W Wet/Dry Tile Saw | 24 | 30 | 27 |

Types of Ceiling Tile Cutters

Choosing the right ceiling tile cutter is essential for achieving precise cuts and maintaining the integrity of the materials. Different types of cutters are suited to specific materials and cutting requirements. Below, we explore the various types of ceiling tile cutters available, each with unique features and applications.

Manual Tile Cutters

Manual tile cutters are preferred for their simplicity and ease of use, making them ideal for smaller projects or less frequent use.

- Advantages:

- No electricity required, making them portable and convenient.

- Generally less expensive than their electric counterparts.

- Easier to control for precision cuts on standard tiles.

- Popular Products:

- Sigma 2B3 25 inch Tile Cutter: Known for its precision and durability, suitable for cutting ceramic and porcelain tiles up to 25 inches.

- QEP 48 in. Manual Tile Cutter: Offers a broader cutting length, ideal for larger tiles used in commercial settings.

- Ideal For: DIY enthusiasts and professionals needing a reliable tool for occasional use without the requirement for power.

Electric Tile Cutters

Electric tile cutters are equipped with diamond blades and are used for intensive, regular cutting. They are perfect for projects requiring multiple or complex cuts, such as tiles with irregular shapes.

- Advantages:

- High power and speed, reducing the time and effort needed for cutting.

- Can handle tougher materials like thick porcelain or stone tiles.

- Usually come with features like water cooling systems to minimize dust and prolong blade life.

- Popular Products:

- DeWalt DWC860W Wet/Dry Tile Saw: Versatile for both wet and dry environments, offering a robust design for continuous use.

- VEVOR Wet Tile Saw 7-inch: Features a powerful induction motor and a steel blade, making it suitable for heavy-duty cutting tasks.

Specialty Tile Cutters

Specialty tile cutters are designed for specific applications, such as cutting mosaic tiles, large format tiles, or making specialty cuts like beveled edges or holes.

- Advantages:

- Designed to perform unique cuts that standard cutters cannot achieve, such as curves or engravings.

- Often includes additional accessories for specific cuts, like hole cutters or jig systems.

- Popular Products:

- Sigma Kera-Cut Extendable 8AE2: Excellent for large format tiles, offering an extendable design for precise cutting.

- Rubi Hit N 48″ Professional Tile Cutter: A top choice for professionals, capable of handling very large tiles with precision.

Dimension Table for Featured Ceiling Tile Cutters

Here is a comparative table showing key specifications of some featured products to help users make an informed decision:

| Tile Cutter Model | Cutting Length (inches) | Max Tile Thickness (mm) | Weight (lbs) |

|---|---|---|---|

| Sigma 2B3 25 inch Tile Cutter | 25 | 15 | 22 |

| QEP 48 in. Manual Tile Cutter | 48 | 12 | 25 |

| DeWalt DWC860W Wet/Dry Tile Saw | 24 | 30 | 27 |

| VEVOR Wet Tile Saw 7-inch | 18 | 30 | 26 |

| Sigma Kera-Cut Extendable 8AE2 | Up to 332 | 19 | 33 |

| Rubi Hit N 48″ Professional Tile Cutter | 48 | 20 | 30 |

Understanding the various types of ceiling tile cutters available and their specific applications can greatly impact the efficiency and quality of your work. Whether you choose a manual, electric, or specialty cutter, the right tool can make all the difference in your tiling projects. For more detailed information and purchasing options, consider visiting pages like How to Cut Tile for further guidance on cutting techniques and tool selection.

Pros and Cons of Different Types of Ceiling Tile Cutters

Choosing the right ceiling tile cutter involves understanding the advantages and disadvantages of each type. This section provides a detailed comparison to help you select the best tool for your specific project needs.

Manual Tile Cutters

Pros:

- Portability: These cutters do not require electricity, making them easily portable and usable in various settings without power access.

- Simplicity: Manual cutters, such as the Sigma 2B3 25 inch Tile Cutter, are straightforward to use, making them suitable for DIY enthusiasts and professionals alike.

- Cost-Effectiveness: Generally less expensive than electric cutters, such as the VEVOR Manual Tile Cutter Single Rail, they offer a budget-friendly option for those with simpler or less frequent cutting needs.

Cons:

- Physical Effort: Requires more physical effort compared to electric cutters, which can be a drawback for large-scale projects.

- Limitation on Materials: Not ideal for very thick or hard materials like porcelain or stone, which may require an electric cutter for efficient cutting.

Electric Tile Cutters

Pros:

- Power and Efficiency: Electric cutters, including models like the DeWalt DWC860W Wet/Dry Tile Saw, provide powerful cutting capabilities and can handle tough materials and thick tiles.

- Precision: These cutters often come with advanced features such as water cooling systems and precision cutting guides, as seen in the VEVOR Wet Tile Saw 7-inch, enhancing the accuracy of cuts.

Cons:

- Cost: Generally more expensive than manual tile cutters, with additional costs for maintenance and blade replacement.

- Portability: Requires a power source, which can limit their use in locations without electrical access.

Specialty Tile Cutters

Pros:

- Specialized Cuts: Designed for specific tasks, specialty cutters like the Sigma Kera-Cut Extendable 8AE2 can make cuts that other cutters cannot, such as large format tiles or intricate shapes.

- Versatility: They often include attachments and features that cater to unique cutting needs, making them invaluable for complex projects.

Cons:

- Cost: These are usually the most expensive types of tile cutters due to their specialized capabilities.

- Complexity: May require more skill to operate, which can be a challenge for non-professionals.

Comparative Table: Manual vs. Electric vs. Specialty Tile Cutters

Here’s a table summarizing the key attributes of these types:

| Type | Pros | Cons | Ideal For |

|---|---|---|---|

| Manual | Cost-effective, portable, easy to use | Limited cutting power, more physical effort needed | Small projects, light materials, DIY |

| Electric | High power, precise, less effort needed | Higher cost, needs power source | Professional use, tough materials, frequent usage |

| Specialty | Can perform unique cuts, high versatility | Expensive, may be complex to use | Specialized projects needing specific cuts |

Recommended Products

Here are some specific product recommendations for each type of cutter:

- Manual: Sigma 2B3 25 inch Tile Cutter for its ease of use and precision.

- Electric: DeWalt DWC860W Wet/Dry Tile Saw for its robust design and versatility in both wet and dry conditions.

- Specialty: Sigma Kera-Cut Extendable 8AE2 for cutting large format tiles with extreme precision.

Recommended Uses for Each Type of Ceiling Tile Cutter

Selecting the right ceiling tile cutter for specific tasks can enhance the efficiency and quality of your work. This section will provide insights into the best uses for manual, electric, and specialty tile cutters, helping you choose the appropriate tool for various applications.

Manual Tile Cutters

Ideal Uses:

- DIY Projects: Perfect for homeowners who need to make occasional cuts on standard ceiling tiles.

- Small Renovations: Suitable for small-scale, quick repair jobs where simplicity and speed are necessary.

- Light Materials: Best used with materials like vinyl, cork, and lightweight acoustic tiles.

Product Highlight:

- Sigma 2B3 25 inch Tile Cutter: Ideal for precision cutting of ceramic and porcelain tiles, making it a great choice for bathroom and kitchen renovations.

- Link to explore: Sigma 2B3 25 inch Tile Cutter

Electric Tile Cutters

Ideal Uses:

- Professional Installation: Recommended for contractors and professionals handling frequent tile installations or large projects.

- Thick and Hard Materials: Capable of cutting through tough materials like porcelain, stone, and thick decorative tiles.

- Precision Cuts: Necessary for jobs requiring high accuracy and clean cuts, especially when working with expensive materials.

Product Highlight:

- DeWalt DWC860W Wet/Dry Tile Saw: Offers robust performance for both wet and dry cutting, suitable for cutting stone and thick tiles.

- Link to explore: DeWalt DWC860W Wet/Dry Tile Saw

Specialty Tile Cutters

Ideal Uses:

- Custom Tile Shapes: When tiles need to be cut into complex shapes or sizes that standard cutters cannot achieve.

- Large Format Tiles: Essential for handling and cutting large format tiles, which are increasingly popular in modern architecture.

- Special Materials: Useful for cutting special materials like glass tiles, which require precise and gentle handling to prevent breakage.

Product Highlight:

- Sigma Kera-Cut Extendable 8AE2: Excellently designed for precision cutting of large format tiles, providing clean cuts with its extendable guide.

- Link to explore: Sigma Kera-Cut Extendable 8AE2

Comparative Usage Table

This table provides a quick reference to match the cutter type with its recommended uses, highlighting the suitability of each product for various tasks:

| Cutter Type | Ideal For | Recommended Product | Product Link |

|---|---|---|---|

| Manual | DIY projects, small renovations, light materials | Sigma 2B3 25 inch Tile Cutter | View Product |

| Electric | Professional installation, thick/hard materials | DeWalt DWC860W Wet/Dry Tile Saw | View Product |

| Specialty | Custom tile shapes, large format tiles, special materials | Sigma Kera-Cut Extendable 8AE2 | View Product |

Key Features to Consider: Blade Quality and Material

When selecting a ceiling tile cutter, the quality and material of the blade are critical factors to consider. These elements directly influence the cutter’s effectiveness, durability, and suitability for specific materials. Understanding these features can help you choose the right tool for your tiling projects.

Blade Quality

Importance of Blade Quality:

- Precision Cutting: A high-quality blade ensures clean and precise cuts, reducing material wastage and potential damage to the tiles.

- Durability: Premium blades remain sharp longer and require less frequent replacements, offering better long-term value.

Recommended Products:

- DeWalt DWC860W Wet/Dry Tile Saw: Known for its robust diamond blade, suitable for both wet and dry cutting environments. This tool provides durability and precision for cutting tough materials like porcelain and stone.

- Rubi Hit N 48″ Professional Tile Cutter: Equipped with a high-quality scoring wheel that offers excellent performance on ceramic and porcelain tiles.

Blade Material

Types of Blade Materials:

- Diamond Blades: The hardest and most durable option, ideal for cutting very hard materials such as stone and thick tiles.

- Tungsten Carbide Blades: Common in manual tile cutters, these blades offer a good balance of durability and cost, suitable for ceramic and softer tile materials.

Recommended Products:

- Sigma Kera-Cut Extendable 8AE2: Uses a tungsten carbide scoring wheel that is perfect for precision cuts on large format tiles.

- VEVOR Wet Tile Saw 7-inch: Features a diamond blade that excels in fast and clean cuts through tougher materials.

Selecting the Right Blade for Your Needs

To choose the most appropriate blade for your ceiling tile cutter, consider the following tips:

- Assess Material Hardness: Determine the hardness of the materials you will be cutting most frequently. Harder materials will require a diamond blade for effective cutting.

- Consider Tile Thickness: Ensure the blade can handle the thickness of your tiles without chipping or breaking them.

- Look for Compatibility: Some cutters allow for blade replacements. Make sure the blades are compatible with your cutter model for easy swaps.

Blade Recommendations and Links

- Diamond Blades:

- Calidad Turbo Diamond Saw Blades – Best for users needing to cut very hard or dense tiles.

- VEVOR Wet Tile Saw 7-inch 65Mn Steel Blade 3500 RPM Induction Motor – Ideal for frequent use in demanding conditions.

- Tungsten Carbide Blades:

- Sigma 2B3 25 inch Tile Cutter – Excellent for precision cutting of ceramic tiles in smaller projects.

- TILER 48 Inch Manual Tile Cutter – Provides adjustable laser guide for accurate cuts on larger tiles.

Key Features to Consider: Handle Design and Ergonomics

Handle design and ergonomics play a vital role in the usability, efficiency, and safety of ceiling tile cutters. A well-designed handle reduces user fatigue, provides better control, and ensures smoother operation, especially during prolonged use.

Importance of Handle Design in Ceiling Tile Cutters

Key Considerations:

- Comfort: Handles with soft grips or rubberized coatings provide a more comfortable experience, reducing strain on the hands.

- Control: A sturdy and well-positioned handle offers precise control over the cutting tool, essential for clean, accurate cuts.

- Safety: Ergonomically designed handles minimize the risk of slipping, ensuring safer operation.

Ergonomic Features in Popular Ceiling Tile Cutters

Here are examples of ceiling tile cutters with excellent ergonomic handles:

- Rubi Hit N 48″ Professional Tile Cutter: This model features a dual grip handle designed for stability and precision, making it ideal for large-scale projects.

- Quinn Heavy Duty Tile Cutter: Includes a cushioned handle to reduce hand fatigue during extended use, suitable for professionals working on demanding projects.

- Sigma TC2B3 26″ Pull Tile Cutter: Equipped with a smooth pull handle that allows effortless operation while maintaining cutting accuracy.

Types of Handles and Their Applications

| Handle Type | Advantages | Recommended Models |

|---|---|---|

| Soft-Grip Handles | Enhanced comfort and reduced fatigue | Quinn Heavy Duty Tile Cutter |

| Dual Grip Handles | Provides additional stability and control | Rubi Hit N 48″ Professional Tile Cutter |

| Pull Handles | Easy operation with precision in cutting | Sigma TC2B3 26″ Pull Tile Cutter |

Tips for Selecting Ergonomic Handles

- Weight Balance: Choose a tile cutter where the handle design complements the overall weight distribution for better maneuverability.

- Material Durability: Opt for handles made from high-quality materials like rubber or aluminum for longevity and reliability.

- Test for Fit: Ensure the handle design fits comfortably in your hand, especially if you’ll use it for extended periods.

Recommended Uses for Ergonomic Handles

- For Large Projects: Handles with dual grips, like the one in the Rubi Hit N 48″ Professional Tile Cutter, provide better stability and are ideal for cutting large or heavy tiles such as 2 by 4 ceiling tiles.

- For DIY Tasks: Cutters like the Quinn Heavy Duty Tile Cutter are suitable for home improvement enthusiasts due to their ease of use and comfort-focused handle design.

Additional Resources

To further understand how ergonomics impact tile cutting, explore the following resources:

- How to Cut Tile – Comprehensive guide to mastering tile cutting techniques.

- Electric Tile Cutter – For insights into advanced cutters with ergonomic designs.

Selecting a ceiling tile cutter with a well-designed handle can significantly enhance your efficiency and precision, ensuring a smoother and safer tile-cutting experience.

Key Features to Consider: Safety Features

Ensuring safety while using ceiling tile cutters is crucial, particularly when handling sharp blades and potentially hazardous materials. Various safety features are designed to protect users from injuries and to make tile cutting a more secure task.

Essential Safety Features in Ceiling Tile Cutters

Blade Guards:

- Purpose: Prevents direct contact with the blade during operation, significantly reducing the risk of cuts.

- Example: The DeWalt DWC860W Wet/Dry Tile Saw is equipped with a robust blade guard that provides superior protection while allowing for precise cuts.

Non-Slip Handles:

- Purpose: Ensures a firm grip even with wet or slippery hands, enhancing control and stability.

- Example: Sigma 2B3 25 inch Tile Cutter features an ergonomically designed handle with a non-slip rubber grip for increased safety and comfort.

Locking Mechanisms:

- Purpose: Secures the blade in a fixed position when not in use, preventing accidental deployment.

- Example: Rubi Hit N 48″ Professional Tile Cutter includes a locking mechanism that stabilizes the blade during transport and storage.

Advanced Safety Technologies

Automatic Shut-Off:

- Purpose: Electric tile cutters often include an automatic shut-off feature that stops the blade if the machine overheats or if an unsafe operational condition is detected.

- Example: VEVOR Wet Tile Saw 7-inch integrates an automatic shut-off for overheating, ensuring both the safety of the user and the longevity of the machine.

Finger Protection:

- Purpose: Some cutters come with finger guards to keep hands at a safe distance from the cutting blade during operation.

- Example: Quinn Heavy Duty Tile Cutter incorporates a clear finger guard that allows users to see the cutting line without exposing fingers to the blade.

Safety Guidelines for Ceiling Tile Cutters

- Regular Maintenance: Keep the cutter in good condition; regularly check and replace worn-out blades and parts.

- Proper Use of Equipment: Always use the tile cutter for its intended purpose and follow the manufacturer’s instructions.

- Wear Protective Gear: Always wear appropriate safety gear, including gloves, goggles, and ear protection, especially when using electric tile cutters.

Recommended Safety-Featured Products

- DeWalt DWC860W Wet/Dry Tile Saw: Ideal for heavy-duty cutting with enhanced blade guard and automatic shut-off features.

- Sigma 2B3 25 inch Tile Cutter: Best for manual tile cutting with ergonomic and non-slip handle design for safety.

Step-by-Step Guide: How to Cut Ceiling Tiles

Cutting ceiling tiles accurately and safely requires careful preparation and attention to detail. Below, we provide a comprehensive guide tailored to cutting standard 2 by 4 ceiling tiles, ensuring you achieve professional results whether you’re renovating an office space or updating a home.

Preparation and Safety Tips

Before beginning any tile cutting project, it is crucial to prepare your workspace and ensure all safety measures are in place.

Preparation:

- Measure and Mark: Accurately measure the area where the tiles will be installed and mark the tiles for cutting using a pencil or chalk line for visibility.

- Secure Workspace: Ensure your cutting surface is stable and robust, preferably a workbench or a cutting table.

- Select the Right Tool: Depending on the material of your ceiling tiles (e.g., acoustic, fiberglass, or mineral fiber), choose a suitable tile cutter. For most 2 by 4 ceiling tiles, a manual tile cutter or an electric tile saw like the DeWalt DWC860W Wet/Dry Tile Saw is appropriate.

Safety Tips:

- Wear Protective Gear: Always wear safety goggles, gloves, and a dust mask to protect against flying particles and dust.

- Check Equipment: Before use, ensure all equipment is in good working order, especially the safety features like blade guards and non-slip handles.

- Keep a Clean Area: Maintain a clean workspace to avoid accidents caused by slipping on debris or tripping over equipment.

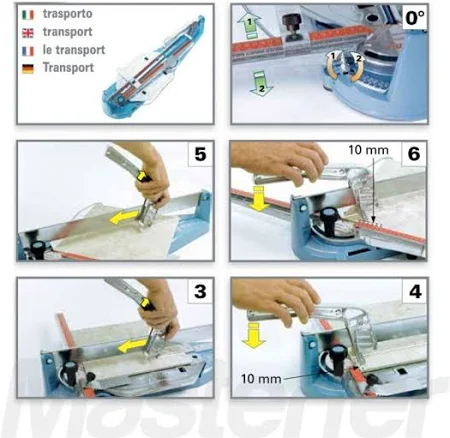

Detailed Steps for Cutting Standard 2 by 4 Ceiling Tiles

Follow these steps to cut your ceiling tiles accurately and efficiently:

Set Up Your Cutter:

- For manual cutters like the Sigma 2B3 25 inch Tile Cutter, ensure the blade is sharp and the cutting wheel is in good condition.

- For electric cutters, verify that the saw is stable and securely mounted, and the blade is suitable for the tile material.

Measure and Mark the Tile:

- Use a straightedge and a pencil to mark where you will cut the tile. Double-check measurements to ensure accuracy.

Position the Tile:

- Place the tile securely against the fence of the tile cutter. For tiles that need to be cut to fit around obstacles (like light fixtures), measure and mark the cutout areas clearly.

Begin Cutting:

- For manual cutters: Press down on the handle and push the cutting wheel across the tile surface, applying even pressure to score the tile before snapping it along the scored line.

- For electric saws: Turn on the saw and gently push the tile through the blade, keeping your hands away from the cutting path. Feed the tile slowly and steadily.

Check the Fit:

- After cutting, place the tile in its designated space to ensure it fits properly. If adjustments are needed, mark the areas and repeat the cutting process.

Final Touches:

- Sand or trim any rough edges using a tile file or sandpaper to ensure a smooth finish that will sit flush against the grid.

Step-by-Step Guide: How to Handle Special Tiles Like Beveled Tegular Ceiling Tiles

Beveled tegular ceiling tiles add a visually appealing dimension to any room, thanks to their unique edges that drop below the grid system. These tiles can be challenging to cut due to their design, requiring specific handling and cutting techniques to ensure a professional finish without damaging the tile.

Preparation and Tools Required

Before you start cutting beveled tegular ceiling tiles, proper preparation is key to ensure accuracy and safety.

Tools and Materials Needed:

- Tile Cutter: For beveled tegular tiles, a precise tile cutter capable of handling delicate edges is recommended, such as the Sigma 2B3 25 inch Tile Cutter.

- Measuring Tape and Pencil: For accurate measurements and marking where cuts will be made.

- Safety Equipment: Safety goggles, gloves, and a dust mask to protect against tile dust and debris.

Step-by-Step Cutting Process

1. Measure and Mark the Tile:

- Accuracy is Key: Measure the space where the tile will be installed. Transfer these measurements onto the tile using a pencil. Ensure all lines are straight and clear.

2. Setting Up the Tile Cutter:

- Proper Alignment: Place the tile in the tile cutter. Align the blade with the marked line on the tile. For tegular tiles, ensure the beveled edge is facing the correct direction to avoid chipping.

3. Cutting the Tile:

- Gentle and Steady: Press down on the handle of the tile cutter and push the blade across the tile. Apply steady pressure to score the tile first, then press down to break the tile along the scored line. For beveled edges, use a slower, more controlled approach to maintain the integrity of the bevel.

4. Finishing Touches:

- Smoothing Edges: Use a tile file or fine-grit sandpaper to smooth any rough edges after cutting, particularly along the beveled edge to ensure it fits neatly and safely into the grid.

5. Dry Fitting:

- Ensure Perfect Fit: Before securing the tile into place, perform a dry fit to ensure it fits perfectly within the grid without forcing. Adjust if necessary.

Tips for Handling Beveled Tegular Tiles

- Double-Check Measurements: Due to the unique shape of beveled tegular tiles, it’s crucial to double-check measurements before cutting.

- Avoid Excessive Force: When snapping the tile along the scored line, apply gentle pressure to avoid damaging the bevel.

- Cut from the Back: If using a wet saw, cut from the back of the tile to prevent chipping the decorative face.

Recommended Products for Beveled Tegular Ceiling Tiles

- Sigma 2B3 25 inch Tile Cutter: Ideal for precision manual cutting.

- DeWalt DWC860W Wet/Dry Tile Saw: For more complex cuts or thicker materials, this wet/dry saw offers precision and power.

Using Specialty Cutters: How to Use a Reveal Cut Tool

Reveal cut tools are specialized tools designed to make precise cuts along the edges of ceiling tiles, creating a “reveal” or a small lip that tucks away into the ceiling grid system. This guide will detail the steps to effectively use a reveal cut tool, such as the Sigma Series 4 NEX Push Tile Cutter, to handle custom modifications needed for installing tiles around fixtures or at the edge of the wall.

Preparation and Setup

Necessary Tools and Equipment:

- Reveal Cut Tool: For example, the Sigma Series 4 NEX Push Tile Cutter is ideal for making precise reveal cuts.

- Measuring Tape and Pencil: Essential for accurate measurement and marking where cuts are needed.

- Safety Gear: Safety goggles, dust mask, and gloves to protect against tile dust and sharp edges.

Setting Up Your Workspace:

- Ensure your work surface is stable and clear of any unnecessary tools or debris.

- Position your reveal cut tool securely on the workspace.

Step-by-Step Guide to Using a Reveal Cut Tool

1. Measure and Mark the Tile:

- Accurately measure the required dimensions on the ceiling tile where the reveal needs to be created.

- Use a pencil to mark the line where the cut will be made.

2. Adjust the Reveal Cut Tool:

- Set the cutting depth on the tool to match the thickness of your ceiling tile. This ensures that the blade cuts through the tile but does not excessively penetrate, which could damage the tool or the tile.

- Align the tile in the tool so that the marked line matches the path of the blade.

3. Make the Cut:

- Operate the reveal cut tool by pushing the blade along the marked line. For tools like the Sigma Series 4 NEX, which is manually operated, ensure a steady, controlled push to maintain a straight cut.

- If your tool is electric, such as the VEVOR Wet Tile Saw, turn it on and guide the tile smoothly through the blade.

4. Check and Finish:

- After cutting, remove the tile and inspect the edge to ensure the cut is clean and the reveal is as desired.

- Use a fine-grit sandpaper to smooth out any rough edges along the cut to prevent any fitting issues or visible imperfections.

5. Install the Tile:

- Fit the cut tile into its designated spot within the ceiling grid. The reveal should snugly tuck into the grid, providing a clean, professional appearance.

Safety and Maintenance Tips

- Regular Maintenance: Keep your reveal cut tool in good condition by regularly cleaning and replacing the blade when it becomes dull.

- Safety First: Always use safety equipment and follow the manufacturer’s guidelines to prevent accidents.

Techniques for Using a Tile Hole Cutter

Tile hole cutters are essential tools for creating precise holes in ceiling tiles for fixtures, vents, or intricate decorative designs. This guide will detail the steps and techniques to effectively use a tile hole cutter, focusing on specialty tools like the VEVOR Wet Tile Saw and manual hole cutters for precise cuts in various tile materials.

Preparation and Setup

Tools and Materials Needed:

- Tile Hole Cutter: Choose a cutter suitable for the tile material. For manual cutting, a simple hole saw or an adjustable hole cutter might suffice. For tougher materials, consider a wet tile saw with a hole-cutting setup.

- Measuring Tape and Pencil: For accurate placement and sizing of the hole.

- Drill (if using a hole saw attachment): To start the hole, especially in harder tile materials.

- Safety Equipment: Safety goggles, gloves, and a dust mask to protect against sharp edges and tile dust.

Setting Up Your Workspace:

- Secure a stable and clean work surface, free from clutter that could interfere with the cutting process.

- Position your tile securely on the workspace, ensuring it will not shift during cutting.

Step-by-Step Guide to Using a Tile Hole Cutter

1. Measure and Mark the Tile:

- Determine the exact location where the hole needs to be made. Measure carefully to center the hole or place it precisely where needed for fixtures.

- Mark the center point of the hole on the tile using a pencil.

2. Select the Appropriate Hole Cutter:

- For small to medium holes, a standard hole saw attached to a power drill is suitable. Ensure the hole saw is the correct size for your needs.

- For larger holes or more precise cuts, use a specialized tile hole cutter like the VEVOR Manual Tile Cutter that can adjust to various sizes.

3. Drill a Pilot Hole (if necessary):

- For manual hole cutters or when using a hole saw, drill a pilot hole at the mark. This will guide the larger cutter and prevent it from slipping.

4. Cut the Hole:

- Using a Hole Saw: Attach the hole saw to your drill, align it with the pilot hole, and begin drilling at a steady speed. Apply gentle pressure and keep the drill straight to avoid cracking the tile.

- Using a Manual Tile Hole Cutter: Align the cutter over the marked point, adjust it to the correct size, and apply pressure evenly while rotating the cutter to score and then cut through the tile.

5. Finish the Edges:

- Smooth the edges of the hole using a tile file or fine-grit sandpaper. This prevents chipping and ensures the fixture or element the hole is made for will fit properly.

Tips for Success

- Lubricate the Cutter: If using a wet tile saw or a hole saw, periodically spray water or a lubricant to keep the cutting surface cool and reduce dust.

- Go Slow: Especially with harder tile materials, take your time to prevent cracking or chipping the tile.

- Support the Tile: Make sure the tile is fully supported around the cut area to prevent breakage.

Maintenance and Care: Cleaning and Storing Your Ceiling Tile Cutter

Proper maintenance and care of your ceiling tile cutter are crucial for ensuring longevity and optimal performance. This guide covers essential practices for cleaning and storing your ceiling tile cutter, using examples like the Sigma 2B3 25 inch Tile Cutter and other related tools to demonstrate best practices.

Cleaning Your Tile Cutter

Routine Cleaning Steps:

- Remove Debris: After each use, brush off any tile residue and dust from the cutter. A soft brush or cloth is effective for this initial cleaning.

- Wipe Down Surfaces: Using a damp cloth, wipe down all surfaces of the tile cutter. Avoid using harsh chemicals or solvents that could damage the metal or coatings. For the Sigma 2B3 25 inch Tile Cutter, a mild detergent mixed with water is sufficient for cleaning the metal parts without causing corrosion.

- Lubricate Moving Parts: Apply a light machine oil to any moving parts, such as the scoring wheel and sliding mechanisms, to ensure smooth operation. Tools like the VEVOR Manual Tile Cutter benefit significantly from regular lubrication due to their manual sliding components.

Deep Cleaning:

- Disassemble (if necessary): For a thorough cleaning, disassemble parts of the tile cutter that are easily removable. This might include the cutting wheel, handle, and guide rails.

- Clean Each Part: Use a mild cleaning solution to clean each part thoroughly. For tough stains or buildups, a soft-bristled brush can help remove debris without scratching the surfaces.

- Dry Thoroughly: Before reassembling the tile cutter, ensure all parts are dry to prevent rusting or corrosion, especially important for tools stored in damp locations.

Storing Your Tile Cutter

Proper Storage Solutions:

- Dry Environment: Store your tile cutter in a dry environment to prevent rust and corrosion. Tools like the DeWalt DWC860W Wet/Dry Tile Saw are particularly susceptible to damage if left in moist conditions.

- Protective Covering: Use a protective cover or store the cutter in a case to protect it from dust and other environmental factors. The Sigma Series 4 NEX Push Tile Cutter comes with its carrying case, which provides excellent protection when not in use.

- Avoid Ground Storage: Store the cutter off the ground to prevent it from being knocked over or subjected to potential flooding or spills.

Regular Inspections:

- Check for Rust: Regularly inspect your tile cutter for signs of rust or wear. Tools like the Sigma TC2B3 26″ Pull Tile Cutter should be checked frequently due to their extensive metal components.

- Test Functionality: Before use, test the tile cutter to ensure all parts are working correctly. This ensures that any maintenance issues are addressed promptly, preventing further damage or poor performance during use.

Recommended Products for Maintenance

- Lubricants: Use a high-quality lubricant like WD-40 or a silicone-based lubricant to maintain smooth operation and protect metal surfaces.

- Cleaning Cloths: Microfiber cloths are ideal for cleaning delicate surfaces without scratching.

- Brush Set: A set of soft brushes can help reach tight spaces and remove stubborn debris without damaging your tile cutter.

Maintenance and Care: When to Replace Blades and Parts

Maintaining your ceiling tile cutter in top condition involves regular inspections and timely replacement of blades and parts. Knowing when to replace these components ensures that your cutter operates efficiently and maintains safety standards. Below, we outline the indicators and guidelines for replacing blades and parts of your ceiling tile cutter.

Indicators for Replacement

Blade Wear and Tear:

- Dullness: If the blade no longer cuts cleanly and requires more force to cut through tiles, it’s a sign of dullness.

- Chipping or Damage: Visible chips or cracks on the blade edge can compromise the quality of the cut and potentially harm the user.

Part Wear and Tear:

- Movement Parts: Any wobbling or instability in parts such as the cutting head or handle indicates wear that could affect the cutter’s precision.

- Visible Damage: Cracks, severe rust, or breakage in components like the cutting wheel, rails, or support structures necessitate immediate replacement to ensure safety and functionality.

Routine Check and Replacement Guidelines

Blades:

- Regular Inspection: Check the sharpness and condition of the blade after every project or upon visible signs of wear. Tools like the Sigma 2B3 25 inch Tile Cutter benefit from a routine check to maintain optimal performance.

- Replacement Frequency: Replace the blade every 6 to 12 months, depending on usage frequency and tile material types. Harder materials like porcelain will require more frequent changes.

Parts:

- Annual Inspection: Conduct a thorough inspection of all moving parts and fixtures annually. Pay particular attention to parts that endure significant wear, such as scoring wheels and sliding mechanisms.

- Replacement on Malfunction: Immediately replace any part that does not operate as intended or shows signs of damage.

Recommended Products and Tools

Blades:

- For cutting standard tiles: Standard carbide or titanium-coated blades are usually sufficient.

- For tougher materials: Diamond-tipped blades, such as those found in Vevor Tile Cutters, offer enhanced durability and performance.

Parts:

- Scoring Wheels: Options like the Sigma 7F Standard 14′′ Pull Handle Tile Cutter feature easily replaceable scoring wheels.

- Guide Rails and Supports: Ensure these are compatible with your model. Check specifications or consult with the manufacturer for replacements.

Maintenance Best Practices

- Lubricate Moving Parts: Regularly lubricate all moving parts to reduce wear and prevent rust. Use a light machine oil or a silicone-based lubricant.

- Clean After Use: Remove tile debris and dust after each use to prevent build-up, which can prematurely wear out parts.

- Store Properly: Keep your tile cutter in a dry, dust-free environment to avoid rust and corrosion, which can necessitate premature part replacement.

Maintenance and Care: Cleaning and Storing Your Ceiling Tile Cutter

Proper cleaning and storage of your ceiling tile cutter are vital for maintaining its longevity and performance. Below, we delve into the best practices for cleaning and storing various types of ceiling tile cutters, ensuring they remain in optimal condition for your next project.

Cleaning Your Ceiling Tile Cutter

Post-Use Cleaning:

- Remove Debris: After each use, clear any tile fragments or dust from the cutter. This can be done using a brush or compressed air to ensure that the cutting wheel and guide rails are free from obstructions.

- Wipe Down Surfaces: Use a damp cloth to wipe down the body of the cutter to remove dust and tile residue. For metal parts, consider using a mild cleaner to avoid corrosion or staining.

Deep Cleaning:

- Lubrication: Regularly apply a light machine oil to the scoring wheel and any moving parts to keep them operating smoothly. This is especially important for cutters like the Sigma 2B3 25 inch Tile Cutter, which rely on smooth mechanisms for precise cuts.

- Check for Rust: Inspect for signs of rust or corrosion, particularly if you’re using a tile cutter in damp environments. Use rust remover and a protective coating to treat and prevent rust.

Storing Your Ceiling Tile Cutter

Optimal Storage Conditions:

- Dry Environment: Store your tile cutter in a dry area to prevent rust and deterioration of metal components. If you’re using a cutter like the VEVOR Manual Tile Cutter, ensure it’s stored in a moisture-free environment.

- Protective Covering: Use a fabric cover or store in a carrying case to keep dust and moisture out. This is particularly important for precision tools like the Rubi Hit N 48″ Professional Tile Cutter.

Positioning:

- Flat Surface: Always store the tile cutter on a flat surface to avoid warping or bending of the guide rails. Avoid hanging the cutter by the handle, which can lead to misalignment.

- Away from Heavy Equipment: Store your tile cutter away from areas where it could be knocked over or buried under heavier items, which could damage the cutting arm or wheel.

Regular Maintenance Checks

- Monthly Inspections: Regularly check your tile cutter for loose components, particularly the cutting wheel and handle. Tools like the Sigma Kera-Cut Extendable 8AE2 require frequent checks to ensure that all extensions and adjustments are tight and secure.

- Replacement Parts: Keep an eye on wear and tear, especially on consumables like the cutting wheel. Refer to the manufacturer’s guidelines on how often these should be replaced to maintain optimal performance.

Top 5 Ceiling Tile Cutters Reviewed

Selecting the right ceiling tile cutter is crucial for achieving precise cuts and efficient installations. Here, we review five popular models, highlighting their features, advantages, and potential drawbacks.

1. Sigma 2B3 25 inch Tile Cutter

- Key Features: This manual tile cutter is renowned for its durable design and precision. It features a pull handle and a tungsten carbide scoring wheel, making it ideal for cutting ceiling tiles up to 25 inches.

- Pros:

- High precision cutting ability

- Sturdy all-metal construction

- Easy to operate with a smooth pulling action

- Cons:

- Higher price point compared to other manual cutters

- Somewhat heavy, which might affect portability

- Best For: Professional installers who need a reliable tool for frequent use in commercial projects.

2. QEP 48 in. Manual Tile Cutter

- Key Features: This model is equipped with a wide aluminum alloy base and a straight edge adjustable measurement guide. It’s capable of handling tiles up to 48 inches in length.

- Pros:

- Can handle larger tile sizes

- Comes with a long-lasting titanium-coated tungsten carbide cutting wheel

- Adjustable guide for repetitive cuts

- Cons:

- Requires more storage space due to its size

- Not as easy to transport as smaller models

- Best For: Cutting large ceiling tiles or for projects requiring extended straight cuts.

3. VEVOR Manual Tile Cutter 48 inch

- Key Features: Designed for both precision and strength, this tile cutter features a laser guide for accurate cutting and an anti-skid rubber handle for better grip and comfort.

- Pros:

- Laser guide enhances cutting accuracy

- Robust design suitable for heavy-duty use

- Supports up to 48-inch tiles

- Cons:

- The initial setup may be more complex due to additional features

- Heavier than many other manual cutters

- Best For: Professionals needing precise cuts in large format tiles with a reliable guidance system.

4. Rubi Hit N 48″ Professional Tile Cutter

- Key Features: This cutter stands out with its unique mobile breaking system and ability to execute both straight and diagonal cuts with high precision.

- Pros:

- Exceptional durability and build quality

- Mobile breaker for greater versatility in cutting various tile types

- Ergonomic design reduces fatigue

- Cons:

- Premium pricing

- May be overkill for smaller, less complex projects

- Best For: High-volume professional use where versatility and cutting speed are critical.

5. Whizmax Manual Tile Cutter

- Key Features: An affordable option, the Whizmax offers a straightforward setup with decent cutting capabilities for tiles up to 24 inches wide.

- Pros:

- Cost-effective, making it accessible for DIY enthusiasts

- Lightweight and easy to maneuver

- Simple to use for basic projects

- Cons:

- Not suitable for very thick or heavy-duty ceiling tiles

- Less durable construction compared to higher-end models

- Best For: Casual or DIY projects that don’t require the cutting of dense or oversized tiles.

Each of these tile cutters serves specific needs, from heavy-duty professional applications to more casual DIY projects. When choosing a tile cutter, consider the tile size, frequency of use, and the specific features that will best suit your project requirements. This selection offers a range of options that can meet the needs of varying projects and budgets, ensuring precision and ease in your tile cutting tasks.

Tips for Buying a Ceiling Tile Cutter Online

When shopping for a ceiling tile cutter online, it’s essential to carefully consider several factors to ensure you get the right tool for your needs. Here’s a detailed guide to help you make an informed purchase:

1. Determine Your Needs

- Type of Tiles: Understand the type of ceiling tiles you’ll be working with (e.g., acoustic, tegular, beveled) as different cutters work best with different materials and tile profiles.

- Frequency of Use: Consider how often you’ll use the cutter. Frequent use in a professional setting demands a more robust and durable tool compared to occasional DIY projects.

2. Research the Features

- Cutting Capacity: Look for cutters that can handle the size of your tiles. A 48-inch manual tile cutter, like the Vevor 48 inch Manual Tile Cutter, is suitable for large tiles.

- Precision: Tools with guide marks or laser guides, such as the VEVOR Manual Tile Cutter Cutting Machine with Infrared, ensure more accurate cuts.

- Blade Quality: Opt for cutters with durable blades like tungsten carbide or diamond-tipped blades. These materials maintain sharpness longer and provide cleaner cuts.

3. Check User Reviews and Ratings

- Customer Feedback: Read reviews to gauge the product’s reliability and performance in real-world settings. High ratings often indicate a satisfactory user experience.

- Common Issues: Reviews can also highlight any recurring problems with the cutter, such as blade misalignment or difficulty with thicker tiles.

4. Consider Ergonomics and Safety Features

- Handle Design: Ensure the cutter has an ergonomic handle to reduce fatigue, especially important for projects requiring many cuts.

- Safety Features: Features like protective shields or locks enhance safety, preventing accidents during operation.

5. Look at the Brand and Warranty

- Reputable Brands: Choose well-known brands such as Sigma, Rubi, or DEWALT that are known for quality and reliability.

- Warranty: A good warranty can safeguard your investment, providing coverage for any defects or issues.

6. Compare Prices and Check for Deals

- Price Comparison: Shop around to find the best deals. Sometimes, professional tools might be available at a discount during sales events.

- Shipping Costs and Return Policies: Consider these additional factors which can influence the overall cost and convenience of your purchase.

By following these tips, you can confidently select a ceiling tile cutter that meets your specific needs, ensuring a reliable tool that will assist you in achieving professional-quality results in your ceiling projects. Always cross-reference the tool specifications with your job requirements to avoid purchasing a tool that falls short of what’s needed for your specific types of ceiling tiles.

DIY Projects and Creative Uses of Ceiling Tile Cutters

Innovative Ways to Use Ceiling Tile Cutters for Home Improvement

Ceiling tile cutters are not just for cutting ceiling tiles; they can be repurposed for various creative and practical projects around the home. Here’s how you can leverage this versatile tool:

1. Custom Wall Art

- Materials: Use leftover ceiling tiles to create decorative wall pieces.

- Technique: Cut the tiles into intricate designs or shapes with a ceiling tile cutter and paint or finish them to match your home décor.

2. Decorative Ceiling Borders

- Application: Enhance the aesthetic of a room by adding custom cut, patterned borders around the perimeter of the ceiling using beveled ceiling tiles.

- Tool Recommendation: The precision of a Sigma 2B3 25 inch Tile Cutter can help achieve clean and consistent cuts.

3. Refurbished Tile Coasters and Trivets

- Project Idea: Convert old or unused ceiling tiles into coasters or trivets for your dining table.

- Method: Cut the tiles into smaller squares or circles and finish with a heat-resistant sealant.

4. Enhanced Acoustic Panels

- Usage: Improve room acoustics by cutting acoustic ceiling tiles into custom sizes to fit various areas of your room.

- Tool Utilization: Use a handheld tile cutter for more manageable, precise cuts.

5. Creative Backsplashes

- Design: Utilize a tile cutter to shape ceiling tiles into a unique kitchen backsplash.

- Recommendation: A wet saw tile cutter is perfect for intricate cuts and harder tile materials, ensuring a professional finish.

Gallery of Completed Projects for Inspiration

To visualize these ideas, here’s a look at some successfully completed projects:

- Wall Art Installation: Custom-painted ceiling tile pieces arranged in a dynamic composition.

- Decorative Borders: A series of elegantly cut tiles lining the edges of a room, enhancing its architectural beauty.

- Tile Coasters and Trivets: A set of beautifully finished and sealed tile coasters, each with unique patterns.

- Acoustic Wall Paneling: Strategically placed acoustic tiles cut to various shapes across a home theater or studio for sound optimization.

- Kitchen Backsplash: A full backsplash installation featuring cut tiles with customized motifs.

Safety Guidelines for Using Ceiling Tile Cutters

Essential Safety Tips for Cutting Ceiling Tiles

When handling ceiling tiles, especially during cutting, it’s crucial to follow specific safety guidelines to prevent injuries and ensure a smooth operation. Here are some essential safety tips tailored for using ceiling tile cutters:

1. Preparation

- Workspace Setup: Ensure your cutting area is well-lit and free of clutter. A clean workspace reduces the risk of accidents.

- Tool Inspection: Before each use, inspect your tile cutter for any signs of damage or wear. Check blades for sharpness and integrity.

2. During Cutting

- Secure Materials: Always secure the tile with clamps on a stable cutting surface to prevent movement.

- Cutting Technique: Use a steady, controlled motion when scoring and snapping tiles. Avoid rushed or jerky movements which can lead to uneven cuts or breakage.

3. Post-Cutting

- Blade Disposal: Safely dispose of old or worn blades in a puncture-proof container to prevent injury.

- Clean Up: Sweep or vacuum tile debris to prevent slips and maintain a clean work area.

Recommended Protective Gear

Using the correct safety gear is paramount when cutting ceiling tiles to protect against dust, debris, and potential sharp edges. Here’s the essential protective gear:

- Safety Glasses: Protect your eyes from flying particles and dust with safety glasses.

- Dust Mask or Respirator: Ceiling tiles can produce harmful dust. A dust mask or respirator is crucial to prevent inhalation of fine particles.

- Cut-Resistant Gloves: Protect your hands with cut-resistant gloves, especially when handling sharp tools or broken tile pieces.

- Hearing Protection: If using electric tile cutters like the VEVOR Wet Tile Saw, hearing protection is advisable due to the noise levels.

Detailed Guide to Cutting Ceiling Tiles and Related Questions

1. What is the best tool to cut ceiling tiles?

The best tool to cut ceiling tiles depends on the type of tile material. For standard fiber or mineral fiber ceiling tiles, a dedicated ceiling tile cutter or a sharp utility knife works well for straight cuts. For more intricate cuts or if you’re working with metal ceiling tiles, an electric tile cutter like the VEVOR Wet Tile Saw provides precision and can handle tougher materials.

2. How do I cut ceiling tiles?

To cut ceiling tiles, first measure and mark the cut line on the tile using a pencil and a straight edge. If you’re using a manual scorer or a utility knife, score along the line several times before carefully snapping the tile along the scored line. For more complex shapes or multiple cuts, consider using a wet tile cutter.

3. Can 2×4 ceiling tiles be cut to 2×2?

Yes, 2×4 ceiling tiles can be cut down to 2×2. Measure and mark the halfway points on the 2×4 tile, then use a straight edge and a utility knife to score the surface deeply. Snap the tile along the scored line to create two 2×2 tiles.

4. Can you make ceiling tiles look better?

Absolutely, ceiling tiles can be refreshed or customized to better suit your space. Consider painting them with ceiling-specific paint, adding decorative strips to cover seams, or applying vinyl decals for a modern look. For a more substantial update, replacing old tiles with new, stylish options like beveled tegular ceiling tiles can also make a significant visual impact.

5. Can you cut tile with a utility knife?

Yes, you can cut certain types of ceiling tiles with a utility knife, particularly those made of softer materials like mineral fiber or fiberglass. Score the tile several times along the desired cut line, then bend the tile gently to snap it cleanly along the score.

6. How to cut a circle in drop ceiling tile?

To cut a circle in a drop ceiling tile, start by marking the center point of your circle. Use a compass or a circular object as a guide to draw your circle on the tile. Then, use a keyhole saw or a small jab saw to carefully cut along the outline. For cleaner edges, sand lightly after cutting.

7. What do you cut roof tiles with?

Roof tiles made from materials like clay, concrete, or slate require a heavy-duty tool for cutting. An electric wet saw equipped with a diamond blade, like the VEVOR Manual Tile Cutter, is ideal for making straight and angled cuts without cracking the tile.

8. Is it hard to remove ceiling tiles?

Removing ceiling tiles is generally straightforward, especially if they are drop ceiling tiles. Carefully lift the tiles from the grid system and tilt them at an angle to remove them. For glued or stapled tiles, you might need a pry bar to gently lift and remove the tiles without causing damage to the substrate.

9. How to cut a shadow line in a ceiling tile?

To cut a shadow line in a ceiling tile, use a shadowline cutter, which is specifically designed to create a small bevel along the edge of the tile. This bevel allows the tile to sit flush against the T-bar in a drop ceiling, creating a shadow effect. Adjust the blade to ensure only a small portion of the tile is removed, maintaining the structural integrity of the tile.