A Water Tile Cutter, often referred to as a wet saw, is an essential tool for cutting tiles with precision and minimal dust. Unlike traditional dry tile cutters, water tile cutters utilize a water-cooled diamond blade which reduces heat and wear during the cutting process, allowing for cleaner and smoother cuts. Key features of high-performing models such as the Wet Saw Tile Cutters include sturdy construction, adjustable cutting guides, and a splash guard to keep the work area and operator dry.

1.2 Importance of Using a Wet Saw for Tile Cutting

Using a wet saw for tile cutting offers numerous benefits:

- Precision Cuts: Ideal for complex cuts, like angles and L-shapes.

- Reduced Dust and Debris: Water suppresses dust, making it safer and cleaner.

- Versatility: Cuts through various tile materials, including ceramic, porcelain, and stone.

Wet tile saws such as the Best Tile Cutter For Porcelain are preferred for their ability to handle delicate tiles without chipping.

1.3 Overview of Tile Cutting Tools

Tile cutting tools range from manual tile cutters to sophisticated electric tile saws. Here’s a quick breakdown of popular types:

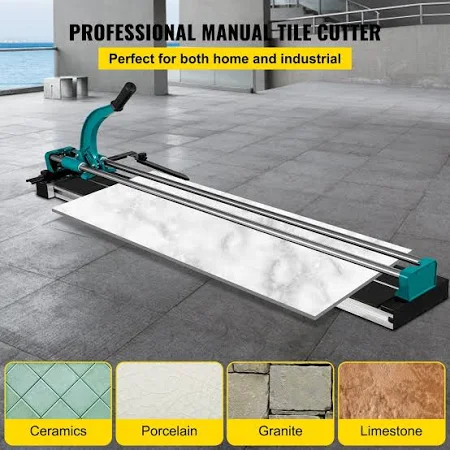

- Manual Tile Cutters: Best for small, straightforward projects. Lightweight and portable, they are ideal for soft ceramic tiles.

- Electric Tile Saws: Use a diamond-coated blade and water system to cut through tiles. Models like the Electric Tile Cutter are suitable for thicker and harder materials.

- Tabletop Wet Saws: These are perfect for jobs requiring high precision and multiple cuts. With features like a sliding table, they provide stability and accuracy.

For specific projects, tools like the Small Tile Cutter and Large Format Tile Cutter cater to different tile sizes and project scales.

2. Types of Tile Cutting Tools

2.1 Water Tile Cutter vs. Dry Tile Cutter

When it comes to selecting the right tile cutter for a project, understanding the key differences between a Water Tile Cutter and a Dry Tile Cutter is crucial. Both types have their distinct applications, advantages, and limitations, which are important for achieving optimal results in tile cutting tasks.

Water Tile Cutter (Wet Saw)

A Water Tile Cutter, commonly known as a wet saw, uses a water-cooled diamond blade to make precise cuts through various tile materials. The presence of water reduces dust and heat, prolonging the blade’s life and making it ideal for cutting dense materials like porcelain and stone.

Key Features:

- Water Cooling System: Reduces dust and cools the blade, allowing for longer cutting sessions.

- Diamond Blade: Provides clean and precise cuts through tough materials.

- Versatility: Capable of executing straight, diagonal, and curved cuts with high precision.

Popular Models:

- SKIL 3540-02 7-inch Wet Tile Saw

- DeWalt D24000R 10 in. Wet Tile Saw

- RIDGID 9-Amp 7-Inch Portable Wet Saw Tile Cutter with Stand

Dry Tile Cutter

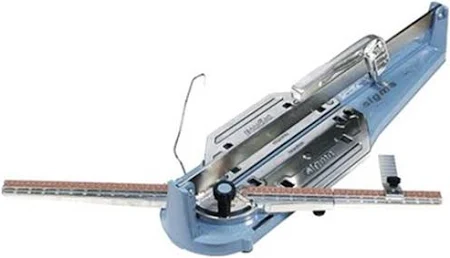

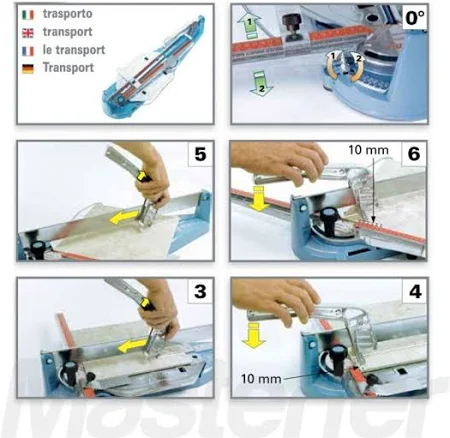

Dry Tile Cutters, on the other hand, are generally manual tools that score and snap the tile. They are simple to use, lightweight, and suitable for small, less complex jobs involving softer tile materials like ceramic.

Key Features:

- No Water Required: Provides a cleaner work environment with less setup.

- Ease of Use: Ideal for quick, straightforward cuts and smaller projects.

- Portability: Can be easily transported and used anywhere without the need for electricity.

Popular Models:

Comparison Table

| Feature | Water Tile Cutter (Wet Saw) | Dry Tile Cutter |

|---|---|---|

| Cutting Mechanism | Diamond blade cooled by water | Manual score and snap |

| Material Suitability | Porcelain, ceramic, stone, thick or large tiles | Ceramic, some porcelains, smaller jobs |

| Dust Production | Minimal due to water | Higher, no water to contain the dust |

| Precision | High precision for complex cuts | Best for straight or simple cuts |

| Portability | Bulkier and requires water setup | Highly portable, no setup required |

| Price | Generally more expensive, professional-grade equipment | More affordable, suited for DIYers |

Product Recommendations

For those looking to purchase a tile cutter, considering the project requirements will guide you to the right choice:

- For complex, large-scale projects or hard materials like stone, a water tile cutter like the DeWalt D24000R is ideal.

- For simple, small-scale projects, a dry tile cutter like the Sigma 2B3 25 inch Tile Cutter is sufficient and budget-friendly.

2.2 Wet Tile Saws: Features and Benefits

A Water Tile Cutter, specifically a wet tile saw, is an invaluable tool for both professional and DIY projects due to its specialized design and functionality. This tool stands out for its use of a water-cooled diamond blade that enables precision cutting with minimal dust and overheating, making it ideal for materials like ceramic, porcelain, and stone.

Key Features of Wet Tile Saws

- Diamond Blade: These saws utilize a high-grade diamond blade for sharp and precise cuts, which is essential for handling brittle materials like glass and dense materials like stone.

- Water Cooling System: Water is continuously applied to the blade during operation. This cooling process not only minimizes dust but also extends the blade’s lifespan and prevents overheating.

- Adjustable Cutting Guide: Most wet tile saws come with adjustable guides that help ensure straight and accurate cuts, which is crucial for detailed tiling projects.

Popular Models and Their Unique Features:

- DeWalt D24000R 10 in. Wet Tile Saw: Offers a large cutting capacity and integrated rail system for cutting large tiles and enhancing precision.

- RIDGID 9-Amp 7-Inch Portable Wet Saw Tile Cutter with Stand: This is highly portable with a stand included, making it ideal for on-site jobs.

- VEVOR Wet Tile Saw 7-inch 65Mn Steel Blade 3500 RPM Induction Motor: Features a robust motor for heavy-duty use and a steel blade for endurance and precision.

Benefits of Using a Wet Tile Saw

- Precision and Versatility: These saws can achieve clean, precise cuts, including bevel, diagonal, and L-shaped cuts, on a variety of tile materials.

- Efficiency in Complex Projects: Wet tile saws are essential for projects requiring numerous accurate cuts, significantly speeding up the process compared to manual methods.

- Dust Reduction: The water flow not only cools the blade but also significantly reduces airborne dust and particles, creating a safer work environment.

Practical Applications

- Home Renovations: Ideal for fitting tiles in kitchens and bathrooms where precise cuts around cabinetry and plumbing are required.

- Outdoor Tiling: Useful for cutting pavers and outdoor tile installations, ensuring durability against elements due to the clean cuts that prevent tile chipping.

Example Usage Scenario:

Imagine tiling a custom-shaped patio with porcelain tiles. A wet tile saw like the DeWalt D24000R can be used to cut large, thick tiles quickly and accurately, ensuring each piece fits perfectly without damage.

Choosing the Right Wet Tile Saw

When selecting a wet tile saw, consider the following:

- Tile Size and Thickness: Ensure the saw can handle the size and type of tiles you plan to cut.

- Power and Blade Size: Choose a saw that provides sufficient power and blade size for your project needs.

- Portability: If working across various sites, consider a lightweight and portable model.

For more specialized guidance, resources like How to Cut Tile offer detailed insights into choosing and using tile saws effectively.

2.3 Tile Table Saws for Precision Cutting

Tile table saws, or stationary wet tile saws, are essential for professionals and serious DIY enthusiasts who require precise, high-volume tile cutting. Compared to handheld models, these saws offer more stability and are ideal for creating exact cuts on a wide range of tile materials, from delicate ceramics to robust porcelain and stone.

Features of Tile Table Saws

Tile table saws are distinguished by several critical features that facilitate accurate and efficient tile cutting:

- Large Cutting Surface: Provides ample space to support bigger tiles, which is essential for projects involving large format tiles.

- Built-in Water Pumps: Continuously spray water onto the diamond blade, reducing heat and preventing dust, thus extending the blade’s life and maintaining a clean work environment.

- Adjustable Cutting Guide: Allows for precise measurements and multiple cuts at consistent sizes, which is crucial for detailed tiling layouts.

Top Models for Consideration:

- DeWalt D24000R 10 in. Wet Tile Saw: Known for its durability and precision, it’s suitable for cutting large and heavy tiles with its extendable table.

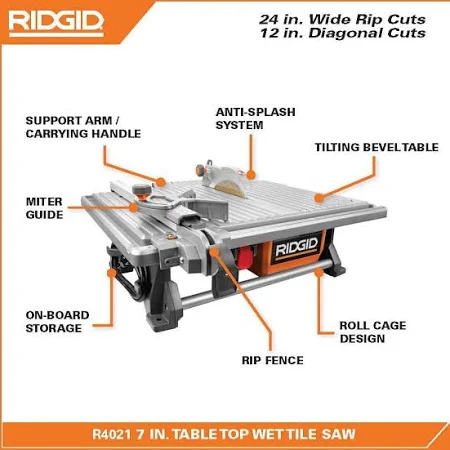

- RIDGID 6.5 Amp Corded 7 in. Table Top Wet Tile Saw: Offers a compact design without compromising on power, perfect for both home renovations and professional job sites.

Benefits of Using Tile Table Saws

Using a tile table saw comes with numerous advantages:

- Precision Cuts with Less Effort: The stability of a table saw allows for more controlled cuts that are straight, clean, and consistent.

- Efficiency: Capable of handling bulk projects quickly, reducing the time spent on cutting without sacrificing quality.

- Versatility: Adjustable settings and powerful motors enable the saw to cut through various thicknesses and materials.

Practical Applications

- Complex Installations: Ideal for projects requiring numerous precise cuts such as herringbone or chevron tile patterns.

- Commercial Projects: Their ability to speed up the process while maintaining accuracy makes tile table saws perfect for large-scale commercial tiling projects.

Example of Application:

A contractor tasked with tiling a large commercial kitchen would benefit immensely from a tile table saw like the DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand, which can manage the size and volume of tiles required for such a large area efficiently.

Choosing the Right Tile Table Saw

When selecting a tile table saw, consider the following factors:

- Power and Size of the Motor: Determines the types of tiles you can cut and the speed of the cuts.

- Size of the Blade: Larger blades allow for deeper cuts, suitable for thicker tiles.

- Overall Size and Portability: Depending on your workspace and storage, ensure the saw can be accommodated and easily moved if necessary.

Safety Tips:

- Always wear protective eyewear and gloves.

- Ensure the work area is well-ventilated, especially when cutting materials that may produce hazardous dust.

2.4 Portable Wet Tile Saws for DIY Projects

Portable wet tile saws are a go-to choice for DIY enthusiasts and professionals who need mobility and convenience without compromising on precision. These saws are designed to handle everything from quick home repairs to significant renovations, providing an effective solution for cutting tiles on the go.

Key Features of Portable Wet Tile Saws

Portable wet tile saws come equipped with features tailored to enhance mobility and ease of use:

- Lightweight Design: Easy to transport from one job site to another, which is especially beneficial for contractors or those working on multiple home projects.

- Compact Size: Smaller dimensions make it easier to store in a garage or workshop without taking up much space.

- Water Recirculation System: Keeps the blade cool and reduces dust, which is ideal for indoor or limited-space environments.

Highlighted Products:

- RYOBI 7 in. Tabletop Tile Saw: Perfect for small to medium DIY projects, offering easy setup and cleaning.

- DeWalt DWC860W Wet/Dry Hand-Held Tile Cutter: Provides versatility to cut both wet and dry tiles, suitable for quick fixes and adjustments on-site.

Advantages of Using a Portable Wet Tile Saw

Opting for a portable wet tile saw brings several benefits that can significantly improve the efficiency and outcome of tile cutting tasks:

- Flexibility: Allows users to cut tiles directly at the installation site, which is crucial for last-minute adjustments.

- Precision: Despite their compact size, they offer clean and precise cuts that are comparable to larger table saws.

- Dust Reduction: Integrated water systems help minimize dust and debris, creating a cleaner working environment.

Practical Use Cases

- Bathroom Renovations: Easily make cuts for tiles around plumbing fixtures and irregular spaces.

- Kitchen Backsplashes: Precisely cut tiles to fit complex patterns or tight spaces behind appliances.

Example Scenario:

Imagine tiling a custom-designed kitchen backsplash with intricate cuts around cabinets and appliances. The RIDGID 6.5 Amp Corded 7 in. Table Top Wet Tile Saw would be ideal for this project, offering the precision necessary for such detailed work without the hassle of a bulky setup.

Selecting the Right Portable Wet Tile Saw

When choosing a portable wet tile saw, consider the following criteria to ensure you get the best fit for your needs:

- Blade Quality: Look for a diamond blade that offers both durability and precision.

- Power Source: Decide between corded and battery-powered models based on your mobility needs and the availability of power outlets at work sites.

- User Reviews: Check online reviews to gauge the reliability and effectiveness of the saw from other DIY enthusiasts and professionals.

Safety Considerations:

- Always check the water reservoir before starting your cut to ensure it’s adequately filled to cool the blade.

- Use appropriate safety gear like goggles and gloves to protect against tile chips and blade contact.

3. How to Choose the Best Tile Cutter for Your Needs

Choosing the right tile cutter is essential whether you are a DIY enthusiast or a professional tiler. It makes the difference between a neatly finished project and one with unsatisfactory results. Here’s what you need to consider to find the best tile cutter for your specific requirements.

3.1 Factors to Consider

When selecting a tile cutter, consider your budget, the types of materials you will be cutting, and the size of the tiles. Each factor plays a crucial role in determining the appropriate tile cutter for your projects.

Budget

- Cost-Effectiveness: Determine how much you are willing to spend. Tile cutters can range from inexpensive manual cutters to high-end electric models.

- Investment vs. Usage: If you are a professional, investing in a higher-end model might be more cost-effective in the long run. For occasional DIY projects, a less expensive model may suffice.

Material

- Type of Tiles: The hardness and size of the tiles you plan to cut will dictate the type of tile cutter you need. For example, cutting porcelain tiles often requires a tile saw with a diamond blade, such as the DeWalt D24000R 10 in. Wet Tile Saw.

- Tile Thickness: Thicker tiles will require a more robust cutting mechanism, often found in electric tile saws like the Rubi DC-250 Python Tile Saw.

Size

- Tile Size: Large format tiles will require a tile cutter with a larger cutting surface and extended cutting length like the Sigma 2D4 Professional Tile Cutter.

- Portability: If your projects require mobility, consider portable models like the Ryobi 7 in. 4.8 Amp Tile Saw with Stand, which offers a balance between size and portability.

Choosing the Right Tile Cutter

- Manual Tile Cutters are suitable for smaller, less complex jobs. They are quieter and usually more portable. Examples include the Sigma Series 4 NEX Push Tile Cutter for precision and ease.

- Electric Tile Saws are ideal for projects requiring extensive cutting of dense materials like porcelain or stone. They provide smooth, precise cuts and can handle larger tiles. Consider models like the VEVOR Wet Tile Saw 7-inch for their power and durability.

Additional Considerations

- Water Source: Wet tile saws require a water source to cool the blade and reduce dust. Ensure you have access to water if you choose a wet saw.

- Safety Features: Look for features such as blade guards and non-slip mats to enhance safety during use.

- Warranty and Support: Consider the warranty and customer support offered by the manufacturer, which can be crucial for professional tools.

Practical Tips

- Always check the compatibility of the blade with the type of tile you are cutting.

- Invest in a good quality diamond blade for cleaner cuts and longer blade life.

- Regularly maintain your tile cutter to ensure it remains in good working condition.

Selecting the right tile cutter involves understanding the specific requirements of your projects and matching them with the features of the tile cutter. Whether you opt for a manual tile cutter for small jobs or a robust electric tile saw for large-scale projects, the right tool will ensure precision and efficiency in your tiling work. By considering the outlined factors and utilizing the recommended products, you can achieve professional-quality results in your tiling projects.

3.2 Wet Saw vs. Electric Tile Cutter

Selecting the right tool for tile cutting is crucial for achieving clean cuts and efficient work. Understanding the differences between a wet saw and an electric tile cutter will help you make the best choice based on your project needs.

Wet Saws

Overview: Wet saws are the go-to choice for professionals and DIYers who need to cut various types of tiles, especially dense or delicate materials like porcelain, stone, or glass.

Advantages:

- Precision Cuts: Offers clean and precise cuts, minimizing tile breakage.

- Water Cooling System: Uses water to cool the blade, reducing dust and extending the blade’s lifespan.

- Versatility: Capable of making straight cuts, bevel cuts, and intricate cuts like L-cuts and U-cuts.

Popular Models:

- DeWalt D24000R 10 in. Wet Tile Saw: Known for its powerful motor and large cutting capacity.

- Rubi DC-250 Python Tile Saw: Excellent for heavy-duty jobs with precision.

- RIDGID 9-Amp 7-Inch Portable Wet Saw Tile Cutter with Stand: Ideal for jobs requiring mobility.

Usage Tips:

- Ensure the water pump is always functioning to keep the blade cool.

- Regularly replace the water in the reservoir to prevent sludge buildup.

Electric Tile Cutters

Overview: Electric tile cutters, often referred to as tile saws without a water cooling system, are suitable for smaller projects or tiles that require less intensive cutting.

Advantages:

- Dry Cutting: No need for a water source, which makes them more suitable for quick jobs or environments where water use is restricted.

- Portability and Ease of Use: Generally lighter and easier to set up than wet saws.

- Cost-Effective: Usually less expensive than wet saws and require less maintenance.

Popular Models:

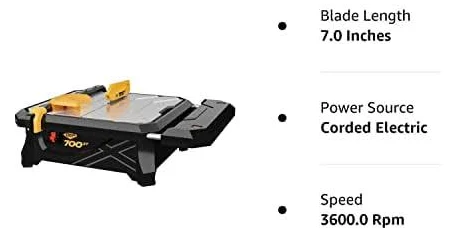

- QEP 700XT Wet Tile Saw: Offers wet cutting features with easy portability.

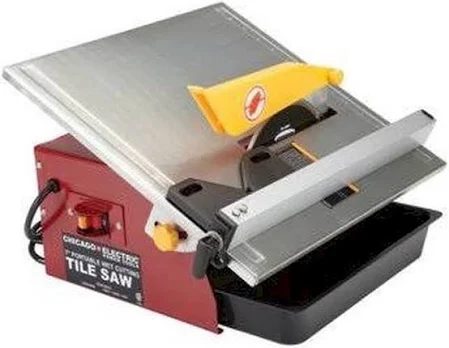

- Chicago Electric 7 in. Portable Wet Cut Tile Saw 69231: A budget-friendly option for casual users.

- Makita CC301DSMJ Tile cutter: A compact electric cutter perfect for small ceramic tiles.

Usage Tips:

- Use a diamond blade for the best cutting results.

- Ensure the blade is compatible with the tile material to avoid damage.

Choosing Between Wet Saw and Electric Tile Cutter

Factors to Consider:

- Material: Harder materials like porcelain and stone nearly always require a wet saw for the best results.

- Project Size: Large projects or frequent use demands the durability and versatility of a wet saw.

- Convenience: Electric tile cutters offer convenience and portability for small or less complex jobs.

Recommendations:

- For versatility and professional-grade cuts, consider the DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand.

- For less frequent usage or smaller projects, the Ryobi 4 in. Tile Saw provides an excellent balance of performance and price.

3.3 Features to Look for in a Tile Saw with Stand

When it comes to heavy-duty tile cutting, having a reliable tile saw with a sturdy stand is essential for efficiency and safety. Tile saws equipped with stands offer enhanced stability and support, which is crucial for precise cuts, especially with larger or heavier tiles. Here’s what you should consider when selecting a wet tile saw with a stand.

Key Features to Consider

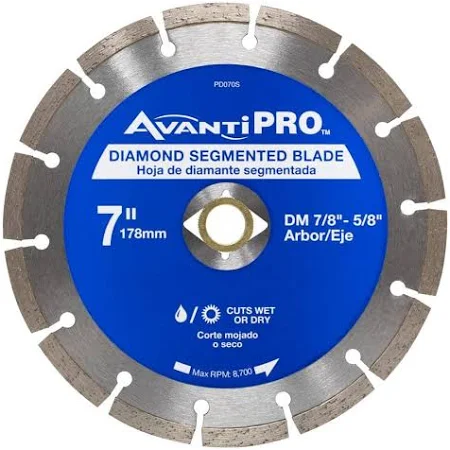

1. Blade Quality and Size:

- Blade Size: Look for a blade that can handle the size of the tiles you are working with. Most professional tile saws feature blades ranging from 7 inches to 10 inches, which can accommodate various tile sizes.

- Blade Quality: Diamond blades are preferred for their ability to cut through tough materials like porcelain and stone without chipping.

2. Motor Power:

- Horsepower: Ensure the motor is powerful enough to deliver smooth cuts without bogging down. A motor with 1-2.5 horsepower is suitable for most cutting tasks.

- RPM (Revolutions Per Minute): Higher RPMs translate to faster cutting speeds, but ensure it’s compatible with the blade size to avoid excessive wear.

3. Stand Stability and Material:

- Material: Look for stands made from durable materials like steel or aluminum that can support the weight of the tile saw and the tiles being cut.

- Design: A stand with adjustable legs is beneficial for leveling the saw on uneven surfaces, which is critical for achieving accurate cuts.

4. Cutting Versatility:

- Beveling Capability: Some tile saws offer beveling capabilities, allowing you to make cuts at various angles, which is essential for jobs that require a more complex layout or design.

- Plunge Cut Feature: This allows for easier cutting of outlets and openings in the middle of the tile, adding to the tool’s versatility.

5. Water Management System:

- Pump Power and Capacity: Efficient water management is crucial to keep the blade cool and minimize dust. Ensure the pump can provide consistent water flow over the blade during extended use.

- Water Recirculation System: Some saws have a system that recirculates water from the pan, reducing the need for frequent refills.

6. Portability and Storage:

- Weight and Size: Consider how easy it is to move and store the saw. Some stands are designed to fold with the saw attached for easy transport and storage.

- Wheels on Stand: Wheels enhance mobility, making it easier to move the setup across different job sites.

Recommended Products

- RIDGID 9-Amp 7-Inch Portable Wet Saw Tile Cutter with Stand: Known for its durability and easy setup, this model is ideal for both professionals and DIY enthusiasts.

- DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand: Offers large capacity cutting along with a robust design for handling various tile sizes and materials.

- Kobalt 7-in 5-Amp Wet Tabletop Tile Saw KWS-B7-20: A more budget-friendly option with essential features for occasional tiling tasks.

4. Top Brands and Models of Tile Cutters

4.1 Home Depot Wet Saws: Pros and Cons

When it comes to choosing a wet tile saw, many professionals and DIY enthusiasts turn to Home Depot for a variety of options. Home Depot’s range includes models from budget-friendly to professional-grade, catering to different needs and project scales. Here, we explore the pros and cons of Home Depot’s wet saw offerings.

Pros of Home Depot Wet Saws

Variety of Choices:

- Home Depot stocks an extensive range of wet saws, including popular brands like RIDGID, Ryobi, and DeWalt. This variety ensures options for all levels of expertise and budget.

- Featured models: RIDGID 9-Amp 7-Inch Portable Wet Saw Tile Cutter with Stand, DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand.

Accessibility and Convenience:

- With numerous locations nationwide, it’s easy to find a Home Depot near you. Additionally, many models are available for online purchase and in-store pickup.

- Rental options: Home Depot offers rental services for higher-end models like the DeWalt Wet Tile Saw with Stand D24000S, which is ideal for those needing a high-quality saw for a one-time project.

Competitive Pricing and Promotions:

- Regular sales and promotions make it possible to purchase a high-quality wet saw at a reduced price.

- Price matching guarantees ensure customers get the best deals available.

Support and Warranty:

- Most wet saws purchased at Home Depot come with a manufacturer’s warranty, plus additional support through Home Depot’s customer service.

- Easy access to spare parts and accessories due to the wide network of suppliers and Home Depot’s comprehensive inventory.

Cons of Home Depot Wet Saws

Variability in Stock:

- Depending on the location, some models might not be readily available in-store, leading to reliance on online orders which can delay project timelines.

Quality Range:

- While Home Depot offers professional-grade tools, some of the lower-priced models may not meet the durability and performance needs of more demanding jobs.

- Reviews on some entry-level models suggest a compromise in build quality and longevity compared to more specialized brands.

Expertise of Staff:

- The level of expertise among Home Depot staff can vary significantly, which might affect the purchasing advice for professional contractors or serious DIYers.

4. Top Brands and Models of Tile Cutters

4.2 DeWalt Tile Saws: A Comprehensive Review

DeWalt is a well-known brand in the tool industry, recognized for its robust construction and precision in performance. Their range of tile saws is no exception, designed to cater to both professional and DIY markets with exceptional features.

Key Models and Features:

DeWalt D24000R 10 in. Wet Tile Saw: This model is renowned for its portability and power, featuring a 10-inch blade that can handle large format tiles with ease. The integrated stainless steel rail system ensures accurate cuts.

- Power: 1.5 HP motor that delivers 4200 RPM.

- Capacity: Rip cut capacity of 24 inches and diagonal cuts on 18-inch tiles.

- DeWalt D24000R 10 in. Wet Tile Saw

DeWalt D36000S High Capacity Wet Tile Saw: Perfect for professionals needing to handle very large tiles. It offers a rip cut capacity up to 37 inches and an integrated stand for stability.

- Innovative features: LED light for better visibility and a plunge feature to make quick plunge cuts for electrical outlets and A/C registers.

- DeWalt D36000S High Capacity Wet Tile Saw

Pros:

- High Precision: With robust rail systems and clear cutting guides, DeWalt saws provide precision that professionals can rely on.

- Durability: Built with high-quality materials that stand up to the rigors of a construction site.

- Versatility: Models designed for various tile sizes, with features like plunge cutting and removable water pans for easy cleanup.

Cons:

- Price: DeWalt’s tile saws are at a higher price point, which might be a significant investment for hobbyists.

- Weight: Some models are heavier, which might affect portability without additional help.

4.3 Ridgid, Florcraft, and Other Popular Tile Saws

Exploring other prominent brands in the tile saw market, Ridgid and Florcraft offer options that appeal to a wide range of users, from occasional DIYers to seasoned professionals.

Ridgid Tile Saws

- RIDGID 6.5 Amp Corded 7 in. Table Top Wet Tile Saw: A compact yet powerful saw that is great for small to medium-sized tile projects.

- Easy to use: Equipped with a clear splash hood for visibility and a diamond blade for precision.

- Mobility: Light enough to transport easily between jobsites.

- RIDGID 6.5 Amp Corded 7 in. Table Top Wet Tile Saw

Florcraft Tile Saws

- Florcraft 7″ Wet Tile Saw: Designed for the cost-conscious user who does not want to compromise on the quality of their cut.

- Budget-friendly: Offers solid performance without the high cost.

- Specifications: Suitable for smaller tiles and less frequent usage.

Comparative Overview

| Brand/Model | Price | Features | Best for |

|---|---|---|---|

| DeWalt D24000R | High | Large capacity, powerful motor, accurate | Professional use |

| RIDGID 6.5 Amp | Moderate | Portable, good for small-medium projects | Home DIY projects |

| Florcraft 7″ | Low | Budget-friendly, easy to use | Occasional use |

5. How to Use a Wet Tile Saw Safely and Effectively

5.1 Setting Up Your Tile Saw

When undertaking any tiling project, a water tile cutter or wet saw is essential for making clean, precise cuts on tiles. Whether you’re cutting ceramic, porcelain, or natural stone tiles, setting up your tile saw correctly is crucial to achieving the best results and ensuring your safety. Here’s a step-by-step guide to setting up a typical wet tile saw, such as the DeWalt D24000R 10 in. Wet Tile Saw or the RIDGID 6.5 Amp Corded 7 in. Table Top Wet Tile Saw.

Preparation:

Choose the Right Location:

- Ensure the area is flat and stable.

- Access to water and electricity is a must.

- Good lighting and ventilation are essential for safety and precision.

Assemble the Saw:

- Follow the manufacturer’s instructions to assemble the saw.

- Attach the water reservoir, ensuring it’s secure and free from leaks.

- Fit the diamond blade correctly, ensuring it’s tight and aligned.

Safety Gear:

- Wear appropriate personal protective equipment:

- Safety goggles or a face shield to protect from flying particles.

- Ear protection if the saw is particularly loud.

- Gloves to maintain a good grip and protect your hands, though they should not be too bulky to compromise safety.

- Wear appropriate personal protective equipment:

Water Setup:

- Connect the Water Supply: Wet tile saws require a continuous flow of water to cool the blade and reduce dust.

- Use the built-in pump to circulate water from the reservoir over the blade, or

- Connect to a direct water supply for continuous fresh water flow.

Test Run:

- Check the Blade and Water Flow:

- Before cutting actual tiles, do a test run to ensure the blade runs smoothly and water adequately covers the blade.

- Adjust the water flow if necessary to prevent over-spraying.

Cutting Guide Adjustment:

- Set the Guide for Precision Cuts:

- Use the cutting guide or fence to align your tiles for accurate cuts.

- Measure and adjust the guide according to the size and type of tile you are cutting.

Safety Check:

- Inspect the Setup:

- Ensure all components are secure before starting your project.

- Double-check the blade for any signs of damage or wear.

- Confirm the saw is stable on its stand and won’t tip over during operation.

Setting up your wet tile saw properly is the first step toward successful and safe tile cutting. Always refer to the specific instructions provided with your saw model, as some features and setups may vary. For example, the Ryobi 7 in. Tabletop Tile Saw might have different alignment features compared to a larger Rubi DC-250 Python Tile Saw. Taking these steps will ensure that you not only protect yourself but also achieve the best possible outcome for your tiling project.

5.2 Step-by-Step Guide to Cutting Tiles with a Wet Saw

Cutting tiles accurately is essential for achieving a professional finish in any tiling project. Using a water tile cutter, commonly referred to as a wet saw, allows you to make precise cuts while minimizing dust and reducing the risk of breaking the tiles. Here’s a detailed guide to cutting tiles using a wet saw like the DeWalt D36000S 10″ High Capacity Wet Tile Saw or the Rubi DC-250 Python Tile Saw.

Before You Start:

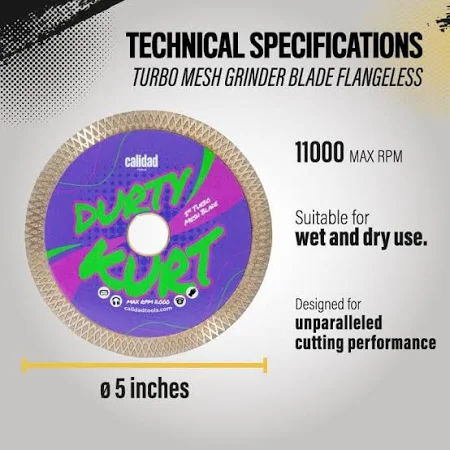

- Select the Appropriate Blade: Depending on the material of your tile—ceramic, porcelain, or stone—choose a diamond blade suited for the material to ensure clean cuts, such as the Calidad Turbo Diamond Saw Blades.

- Measure and Mark Your Tile: Use a pencil or a tile marker to draw your cut lines directly on the tile surface.

Setting Up Your Saw:

Install the Blade:

- Ensure the wet saw is unplugged during setup.

- Install the diamond blade, making sure it is securely attached.

Prepare Water System:

- Fill the reservoir or set up the pump system to ensure adequate water flow over the blade, crucial for reducing dust and cooling the blade.

Adjust the Guide:

- Align the fence or guide of the saw to ensure your tile will be cut straight along the marked line.

Cutting the Tile:

Safety First:

- Wear safety goggles, ear protection, and gloves.

- Keep your hands away from the moving blade.

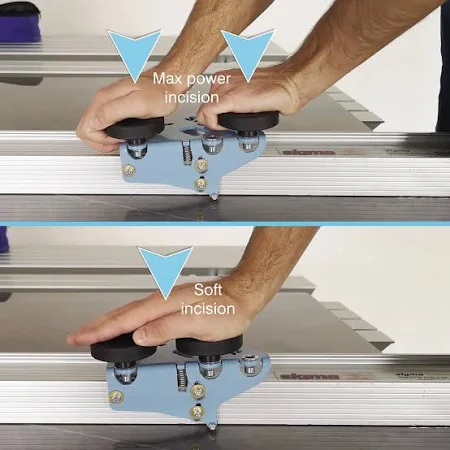

Performing the Cut:

- Turn on the saw and let the blade reach full speed.

- Gently push the tile towards the blade, following the guide. Do not force the tile; let the blade do the work.

- Keep the tile flush against the guide to ensure a straight cut.

Completing the Cut:

- As you near the end of the cut, push the tile through slowly to prevent chipping at the end.

- Turn off the saw and wait for the blade to stop before removing the cut pieces.

Post-Cut Handling:

- Inspect the cut edge. If any smoothing is necessary, gently rub the edge with a rubbing stone or sanding block.

Tips for Complex Cuts:

L-Cuts for Outlets or Switches:

- Mark the area to be removed.

- Make a straight cut from the edge of the tile to the corner of your marked-out section and repeat for all sides that require it.

U-Cuts for Pipes:

- Drill a hole at each corner of the U-cut area with a Glass and Tile Drill Bit to make starting the cuts easier.

- Cut from hole to hole, following the marked lines.

Cleaning Up:

Clean the Saw:

- After your cutting project, clean the saw, blade, and water reservoir to remove any tile debris and slurry to maintain the equipment.

Maintenance Checks:

- Regularly check and replace the blade when you notice signs of wear or if it becomes less effective.

Using a wet saw can significantly enhance your ability to execute various cuts with precision. Models like the DeWalt D36000S and Rubi DC-250 Python Tile Saw are excellent for larger tiles, providing the stability and power needed for frequent use or complex projects. Ensure to follow these steps closely for a safe and successful tile cutting experience.

5.3 Tips for Avoiding Common Mistakes

When using a Water Tile Cutter or any type of wet saw, even the most experienced users can run into issues if they aren’t careful. Understanding the pitfalls can save time, reduce waste, and ensure a clean, precise cut. Here are essential tips to help avoid the most common mistakes made during the tile cutting process.

Mistake #1: Incorrect Blade Choice

- Selecting the Right Blade: Different materials require different blades. For instance, porcelain tiles typically need a harder diamond blade compared to ceramic tiles. Using the Diablo 4-1/2 in. Diamond Turbo Masonry Cut Off ensures precise cuts for tougher materials.

- Blade Installation: Always check that the blade is properly installed. An incorrectly mounted blade can lead to uneven cutting and potential breakage.

Mistake #2: Inadequate Water Use

- Water Flow: Ensure your wet saw’s water pump is functioning correctly to keep the blade cool and minimize dust. A lack of water can cause overheating and reduce the blade’s lifespan.

- Check Reservoirs: Regularly check water levels in stationary wet saws like the RIDGID Tile Saw with Stand. Low water levels can lead to poor blade performance and messy cuts.

Mistake #3: Forcing the Tile Through the Saw

- Feed Rate: Pushing a tile too quickly through the saw can lead to chipping and breakage. The key is to allow the saw to do the cutting at a steady, manageable pace.

- Support During Cutting: For long or large tiles, support the tile properly to prevent snapping. Tools like the Sigma Kera-Cut Extendable 8AE2 can offer extra stability.

Mistake #4: Poor Measurement and Alignment

- Accurate Measurements: Always double-check your measurements before cutting. Use a reliable measuring tape and markers specifically designed for tile work.

- Alignment: Ensure the tile is square against the fence of the tile saw. An angled tile can result in a waste of material and time. For precision, consider using a laser guide featured in tools like the Muzata Tile Cutter 48 inch.

Mistake #5: Not Wearing Proper Safety Gear

- Safety Equipment: Always wear protective eyewear, gloves, and ear protection when operating a wet saw. Tiny shards can cause injury or irritation.

Mistake #6: Improper Cleaning and Maintenance

- Cleaning Post-Use: Clean your saw after each use. This includes clearing the blade of any debris and emptying and cleaning the water tray.

- Regular Maintenance: Regularly inspect your wet saw for any signs of wear or damage, especially the blade. Replace the blade with high-quality options like those from Calidad Turbo Diamond Saw Blades when needed.

Additional Tips:

- Test Cut: Always perform a test cut on a waste piece of tile to ensure the settings and blade are correctly adjusted.

- Sharp Blade: Keep your blades sharp; a dull blade can lead to poor performance and more frequent tile breakage.

- Handling: Handle all tiles with care, especially after cutting, as the edges can be very sharp.

By following these guidelines and using appropriate tools and accessories, you can significantly reduce the likelihood of mistakes and ensure a successful tile installation or project. Whether you are using a high-capacity saw like the DeWalt D36000S 10″ High Capacity Wet Tile Saw or a manual cutter for smaller projects, precision and proper technique are key.

6. Maintenance and Care for Wet Tile Cutters

6.1 Cleaning and Storing Your Tile Saw

Proper maintenance of a Water Tile Cutter or any tile saw is crucial for ensuring longevity and optimal performance. Here’s a detailed guide on how to clean and store your tile saw effectively, using industry-recommended products and techniques.

Cleaning Your Tile Saw

Regular cleaning is essential to prevent buildup that can affect the saw’s performance and potentially damage the tool.

After Use Cleaning:

- Disconnect the Power: Safety first—ensure the tile saw is turned off and unplugged.

- Remove Residual Water: Drain any water from the tray and wipe down the area to prevent rust and sediment build-up.

- Clean the Blade: Using a soft brush, gently clean the Diablo DMADS1000 10″ Diamond Discs for Masonry to remove any debris that might be stuck to the blade.

- Wipe Down Surfaces: With a damp cloth, wipe down all surfaces to remove slurry and tile fragments. Be thorough to ensure no tile grit is left.

Deep Cleaning:

- Blade Inspection and Cleaning: Remove the blade from the saw to clean it thoroughly with a dedicated cleaner such as the ones found in the Project Source Tile Cutter Kit. Inspect the blade for wear and replace it if necessary.

- Check the Water Pump: Ensure the water pump is clear of any tile debris. A clogged pump can affect the cooling efficiency during cuts.

Storing Your Tile Saw

Proper storage of your tile saw is just as important as cleaning it to protect it from environmental factors and ensure it’s ready for next use.

- Dry Completely: Before storing, make sure the tile saw is completely dry to prevent rust. This is particularly important for parts like the Kobalt 7-in 5-Amp Wet Tabletop Tile Saw KWS-B7-20 that are prone to moisture accumulation.

- Safe Storage Area: Store the tile saw in a cool, dry place. If possible, cover it with a waterproof cover to keep dust and moisture out.

- Organize Accessories: Keep all accessories, like blades and cutting guides, together. Use storage solutions such as the Sigma 2B3 25 inch Tile Cutter case for organization and easy access.

Routine Maintenance Checks

- Monthly Inspections: Check for any loose components, especially the blade assembly and water system. Tighten any loose screws and ensure the blade is mounted correctly.

- Lubricate Moving Parts: Use a suitable lubricant on moving parts to ensure smooth operation. Components that benefit from lubrication include the sliding table and blade shaft.

- Blade Replacement: Regularly assess the condition of your blade. A worn-out blade, like those from Calidad Turbo Diamond Saw Blades, should be replaced promptly to maintain cutting efficiency and safety.

Recommended Products for Maintenance

For the best results, use professional-grade maintenance products:

- Cleaning Agents: Opt for non-corrosive cleaning agents that are safe for use on metal and rubber components.

- Lubricants: Choose high-quality lubricants designed for high-performance power tools to ensure longevity and rust protection.

- Storage Covers: Use heavy-duty, moisture-resistant covers to protect your saw from dust and rust.

By adhering to these detailed cleaning and storage guidelines, and using recommended products like the Ryobi 7 in. 4.8 Amp Tile Saw with Stand, you can extend the life of your water tile cutter and ensure it remains a reliable tool for your tiling projects. Regular maintenance not only contributes to the tool’s longevity but also ensures the safety and efficiency of your work.

6. Maintenance and Care for Wet Tile Cutters

6.2 Replacing the Blade on a Tile Cutting Saw

Proper maintenance of a Water Tile Cutter includes timely replacement of the cutting blade to ensure precision and safety during tile cutting. This section provides a detailed guide on replacing the blade of your tile saw, featuring specific products and practical tips for an efficient changeover.

Understanding When to Replace the Blade

A blade should be replaced when you notice:

- Decreased Performance: Cutting becomes more difficult, requiring more force.

- Poor Cut Quality: The cuts are not as clean or precise as they should be.

- Visible Wear: Physical damage or visible wear on the blade edges.

For example, blades like the Diablo DMADS1000 10″ Diamond Discs for Masonry provide visual indicators of wear that help determine the need for replacement.

Steps for Replacing the Blade

Safety First:

- Disconnect the Power: Ensure the tile saw is unplugged or disconnected from any power source.

- Wear Protective Gear: Use gloves and safety goggles to protect your hands and eyes.

Accessing the Blade:

- Remove Blade Guard: Unscrew or unclip the blade guard to expose the blade. Models like the RIDGID Tile Saw with Stand have easily accessible blade guards that facilitate quick changes.

Removing the Old Blade:

- Lock the Blade: Most saws, such as the DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand, feature a blade locking mechanism to prevent the blade from turning while you remove the retaining nut.

- Unscrew the Nut: Use a wrench to turn the nut or bolt counter-clockwise. Keep these components in a safe place as they will be reused.

Installing the New Blade:

- Select the Correct Blade: Choose a blade suitable for the type of tile you are cutting, like the Calidad Turbo Diamond Saw Blades, which are perfect for porcelain or ceramic tiles.

- Align the Blade: Place the new blade on the spindle, ensuring it is facing the correct direction as indicated by the arrow on the blade.

- Secure the Blade: Replace and tighten the nut or bolt clockwise to secure the blade firmly.

Reassembling the Saw:

- Replace the Blade Guard: Reattach the blade guard and ensure it is securely fastened.

- Check the Alignment: Make sure the blade is correctly aligned with the cutting table or guide.

Testing:

- Perform a Test Cut: After the blade is replaced, perform a test cut on a scrap piece of tile to ensure the installation is successful and the saw is functioning properly.

Recommended Products for Blade Replacement

For optimal performance, consider using specialized tools and accessories such as:

- Sigma Kera-Cut Extendable 8AE2 for precise adjustments and settings.

- VEVOR Manual Tile Cutter Single Rail for scoring and snapping tiles cleanly after cutting with a worn blade.

- Rubi DC-250 Python Tile Saw for a robust alternative to your regular tile saw setup, compatible with high-grade diamond blades.

By following these detailed steps and choosing the right products, you can effectively replace the blade on your tile saw, ensuring it remains a reliable tool for your tile cutting needs. This maintenance task not only prolongs the life of your saw but also enhances safety and efficiency in your tile installation projects.

6.3 Troubleshooting Common Issues

Proper maintenance and handling of a Water Tile Cutter can significantly reduce the frequency of operational issues. However, even with meticulous care, occasional problems may arise. This section aims to guide you through some common issues, their likely causes, and how to resolve them efficiently.

Common Problems and Solutions

1. The Blade is Not Cutting Effectively

- Possible Causes:

- Dull blade

- Incorrect blade type for the tile material

- Blade installed backwards

- Solutions:

- Replace the blade with a new one, such as the Diablo DMADS1000 10″ Diamond Discs for Masonry, specifically designed for hard materials.

- Ensure the blade is suitable for the tile material. For porcelain tiles, a blade like the Calidad Turbo Diamond Saw Blades is ideal.

- Check the blade’s direction and reinstall correctly if necessary.

2. The Saw is Overheating

- Possible Causes:

- Inadequate water flow to the blade

- Continuous operation over long periods

- Solutions:

- Check and clean the water pump and nozzle to ensure adequate water flow. The Ryobi 7 in. Tabletop Tile Saw features an easily accessible water reservoir for quick maintenance.

- Allow the saw to cool down periodically during extended use.

3. Chipping of Tile Edges

- Possible Causes:

- Blade too coarse for the tile material

- Excessive feed rate

- Solutions:

- Switch to a finer blade, such as the VEVOR Manual Tile Cutter Single Rail, which offers precision cutting with minimal chipping.

- Adjust the feed rate to allow the blade to cut without pressure.

4. Unusual Noise or Vibration

- Possible Causes:

- Worn bearing or blade shaft

- Loose components

- Solutions:

- Inspect and replace worn parts. The RIDGID Tile Saw with Stand is known for its durability and ease of access for repairs.

- Tighten any loose bolts or fittings to ensure the machine’s stability.

5. Inconsistent Cutting Depth

- Possible Causes:

- Misalignment of the blade or cutting guide

- Worn out blade height adjustment mechanism

- Solutions:

- Realign the blade and adjust the cutting guide. For precision alignment, consider tools like the Sigma Kera-Cut Extendable 8AE2.

- Service or replace the height adjustment components if worn out.

Preventative Measures and Maintenance Tips

- Regular Inspection: Routinely check and maintain critical components like the blade, belt, and motor.

- Proper Cleaning: After each use, clean the tile saw to prevent buildup of tile residue and slurry, which can affect performance.

- Blade Care: Regularly inspect and replace blades with high-quality options like those from Calidad Turbo Diamond Saw Blades to ensure clean cuts and prolonged equipment life.

By understanding these common issues and knowing how to address them effectively, you can extend the lifespan of your Water Tile Cutter and ensure it performs optimally for all your tiling projects.

7. DIY Projects and Applications

7.1 Using a Wet Saw for Ceramic and Porcelain Tiles

When using a Water Tile Cutter or wet saw, like the DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand, the precision in cutting ceramic and porcelain tiles can significantly enhance the quality of your DIY projects. Here’s how to achieve the best results:

- Setup: Ensure the saw is on a stable surface and fill the reservoir with clean water.

- Select the Correct Blade: Use a diamond blade designed for ceramic or porcelain tiles, such as the Diablo DMADS1000 10″ Diamond Discs for Masonry, to ensure a smooth cut.

- Measure and Mark: Accurately measure and mark your tile where the cut is needed. Use a straight edge for straight cuts.

- Feed Tile Slowly: Gently feed the tile into the blade; pushing too fast can cause chipping.

Tips for Success

- Wear Safety Gear: Always wear eye protection and gloves.

- Keep Blade Wet: Ensure the blade is wet during operation to minimize dust and prolong blade life.

- Check Alignment: Regularly check the blade and fence alignment to ensure precision.

7.2 Cutting Large Format Tiles with a Sliding Wet Tile Saw

Large format tiles require a robust setup, such as the Rubi DC-250 Python Tile Saw, which is specifically designed for large tiles.

- Prepare Your Saw: Use a sliding wet tile saw with a large cutting table.

- Proper Blade Selection: Equip it with a blade capable of handling larger tiles, such as the VEVOR Manual Tile Cutter Cutting Machine with Infrared for Porcelain Ceramic.

- Support the Tile: Ensure the entire tile is supported and stable to prevent snapping.

Cutting Process

- Align the Tile: Adjust the tile so the blade aligns with your mark.

- Smooth Operation: Push the table smoothly for an even and precise cut.

7.3 Specialty Uses: Wet Saw for Stone and Pavers

For more rugged materials like stone and pavers, a powerful wet saw such as the Flex CS 40 Wet Tile Saw is recommended.

- Heavy-Duty Blade Required: Use a blade designed for stone and pavers, like the Calidad Turbo Diamond Saw Blades.

- Incremental Feeding: Due to the hardness of the material, feed the stone or paver slowly into the saw to avoid cracking.

Key Considerations

- Regular Water Flow: Ensure there is consistent water flow to keep the dust down and cool the blade.

- Thorough Measurement: Double-check measurements and markings as cutting stone is more final due to the material cost and difficulty.

Each of these applications showcases the versatility of wet tile saws in DIY projects, from delicate ceramic tile installations to robust outdoor paving. With the right techniques and tools, even the most challenging cuts can be made with precision and safety, leading to professional-quality results in your home improvement projects.

Wet Saw vs. Dry Saw: Which is Better?

When choosing between a wet saw and a dry saw for tile cutting projects, it’s crucial to consider the type of tile you’re working with and the desired finish. Both types of saws have their place in construction and DIY projects, but understanding their differences can help determine the best fit for specific needs.

Wet Saws

Advantages:

- Water Cooling System: Wet saws, such as the DeWalt D36000S High Capacity Wet Tile Saw, use water to cool the diamond blade, reducing dust and preventing overheating. This extends the blade’s life and provides clean, smooth cuts.

- Precision: Ideal for intricate cuts, such as angles and L-cuts, without chipping the tile. This is especially important for delicate materials like porcelain and glass.

- Versatility: Capable of cutting through dense materials and large tiles with ease.

Disadvantages:

- Setup Time: Requires setup for water and a suitable workspace to handle water spray and slurry.

- Cost: Generally more expensive than dry saws, making them a significant investment.

Dry Saws

Advantages:

- Portability: Dry saws, like the Makita CC02R1 12V Max CXT Tile/Glass Saw Kit, are more portable and easier to set up since they do not require a water source.

- Convenience: Better suited for quick jobs or where water use is impractical.

- Cost-Effective: Typically less expensive than wet saws.

Disadvantages:

- Dust Production: Creates a significant amount of dust, which can be a health hazard without proper dust extraction.

- Limited Materials: Not recommended for very hard or thick materials, as the lack of cooling can lead to overheating and blade damage.

Comparison Table: Wet Saw vs. Dry Saw

| Feature | Wet Saw | Dry Saw |

|---|---|---|

| Cooling Mechanism | Water cools the blade, reducing dust. | No cooling, higher dust production. |

| Cut Quality | Smooth, precise cuts with minimal chipping. | Can produce rough edges, especially on harder materials. |

| Material Suitability | Ideal for dense, hard, or fragile materials. | Best for softer or thinner materials. |

| Cost | More expensive, requires more maintenance. | Less expensive, fewer operational costs. |

| Setup | Requires preparation and cleanup due to water use. | Quick setup, highly portable. |

Practical Applications

- Wet Saws: Essential for professional installations where precision and quality of cut are paramount, such as in bathroom tiling or kitchen backsplashes. Recommended for materials like porcelain, marble, granite, and glass.

- Dry Saws: Suitable for smaller projects or outdoor jobs where simplicity and speed are required. Good for cutting ceramic tiles or doing basic renovations.

Product Links and Recommendations

For those who prioritize high-quality, clean cuts and are working with challenging materials, a wet saw like the Rubi DC-250 Python Tile Saw is recommended. If you need a more straightforward, less messy solution for quicker or less frequent jobs, consider a dry saw like the Chicago Electric Power Tools Handheld Dry-Cut Tile Saw.

Ultimately, the choice between a wet saw and a dry saw depends on the specific requirements of the project, the types of tiles used, and the working conditions. Both tools have their place in the toolbox of a DIY enthusiast or professional installer, each offering unique benefits tailored to different cutting scenarios.

Top 5 Wet Tile Saws for Sale in 2024

When selecting a wet tile saw, the options can be overwhelming, especially with the advancements in technology and new models hitting the market each year. For 2024, the focus is on efficiency, precision, and user-friendly features. Here, we break down the top 5 wet tile saws, providing detailed insights to help you make an informed decision for your tiling projects.

1. DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand

- Precision: High-capacity cutting for large tile formats up to 37 inches in length and 24 inches diagonally.

- Power: 1.5 HP motor that handles ceramic, porcelain, and stone tiles.

- Features: Integrated stand, robust rail system for smooth and accurate cuts.

- Ideal For: Professionals needing reliability for large-scale projects.

- Purchase Here

2. Rubi DC-250 Python Tile Saw

- Versatility: Cuts both ceramic and porcelain tiles with a powerful 1.5 HP motor.

- Design: Features a mobile head for plunge cuts and a maximum cut length of 48.4 inches.

- Extras: Includes a foldable head for miter cuts at 22.5 and 45 degrees.

- Ideal For: Versatile cutting tasks in both residential and commercial projects.

- Purchase Here

3. VEVOR Wet Tile Saw Tile Cutter 7-inch 65Mn Steel Blade 3500 RPM Induction Motor

- Compact Design: Portable and lightweight, suitable for both floor and tabletop use.

- Speed: Fast cutting with a 3500 RPM blade speed, ideal for quick job completions.

- Cost-Effective: A budget-friendly option without compromising on quality cuts.

- Ideal For: DIY enthusiasts and professionals who need a mobile solution.

- Purchase Here

4. Kobalt 7-in 5-Amp Wet Tabletop Tile Saw KWS-B7-20

- Efficiency: 5-amp motor for handling ceramic, porcelain, and marble up to 1.25 inches thick.

- User-Friendly: Adjustable rip fence with miter gauge for accurate straight and miter cuts.

- Portability: Compact design for easy transport and setup.

- Ideal For: Home renovations and smaller professional jobs.

- Purchase Here

5. Sigma Kera-Cut Extendable 8AE2

- Specialty Tool: Designed for large format tiles, extendable up to 332 cm.

- Precision: Non-slip system with high-performance push scrib handle for smooth scoring.

- Lightweight: Extremely light and comes with a transport bag.

- Ideal For: Specialist contractors working with oversized tiles and requiring precise handling.

- Purchase Here

Each of these wet tile saws has been selected based on their performance, customer reviews, and suitability for different types of tiling projects. Whether you are a DIY enthusiast or a professional, choosing the right wet tile saw can significantly affect the quality of your work and the efficiency with which you complete your projects.

FAQs: Cutting Tiles and Choosing the Right Tools

Should you use water when cutting tiles?

Using water when cutting tiles, especially hard materials like ceramic, porcelain, and stone, is highly recommended due to several benefits:

- Cooling: Water helps cool the cutting blade and tile surface, preventing overheating.

- Dust Reduction: It significantly reduces dust and debris, which can be hazardous to health.

- Better Cuts: Water lubricates the blade, allowing smoother, more precise cuts without chipping.

Is it better to cut tile wet or dry?

- Wet Cutting: Ideal for most tile types, wet cutting ensures clean, precise cuts with minimal dust. Tools like the DeWalt D36000S or the Rubi DC-250 Python Tile Saw are perfect for handling larger or more delicate tiles.

- Dry Cutting: Suitable for quick, small jobs or when working in conditions where water use is impractical. Dry cutting generates more dust and typically wears out blades faster.

What is a good wet tile saw?

A good wet tile saw combines power, precision, and ease of use. For professional use, consider models like:

- DeWalt D36000S 10″ High Capacity Wet Tile Saw with Stand: Offers a robust design suitable for large tiles and heavy-duty projects.

- VEVOR Wet Tile Saw 7-inch: A versatile choice for both DIY enthusiasts and professionals needing portability.

Why is water used to cut tile?

Water serves multiple functions during the tile cutting process:

- Coolant Factor: It prevents the saw blade from overheating, which can compromise its integrity and the quality of the cut.

- Dust Control: Minimizes airborne particles, creating a safer working environment.

- Cut Quality: Reduces friction and heat, providing cleaner cuts with less risk of breaking the tile.

What happens if you cut tile without water?

Cutting tile dry, although feasible in some scenarios, can lead to several issues:

- Increased Wear and Tear: Dry cutting can dull blades faster due to intense friction and heat.

- Health Risks: Produces a significant amount of silica dust, which is harmful when inhaled.

- Poor Cut Quality: Higher risk of chipping or cracking the tile due to excess heat.

Why is wet cutting an effective strategy?

Wet cutting is considered effective due to:

- Enhanced Blade Longevity: Water cools and lubricates the blade, extending its life.

- Health and Safety: Reduces the risk of inhaling silica dust, protecting respiratory health.

- Superior Finish: Ensures smooth cuts, reducing waste due to material breakage.

These insights underscore the importance of choosing the right cutting method and equipment based on the specific requirements of your tile installation project. Whether opting for a robust wet saw like the DeWalt D36000S for extensive tiling needs or a smaller, more portable model, the goal is to achieve precision and safety in every cut.