A laminate floor cutter is a specialized tool designed for the precise cutting of laminate flooring, a popular choice among homeowners due to its durability and aesthetic resemblance to natural wood. Unlike standard saws, laminate cutters deliver clean, fast cuts with minimal dust, making them ideal for indoor use where cleanliness and speed are paramount. Notable models like the EAB Tool Exchange-a-Blade 2100005 9-Inch laminate cutter stand out in the market for their efficiency and reliability.

Importance of the Right Tools for Flooring Installation

Selecting the right tools for flooring installation is not merely a convenience but a necessity for achieving professional-quality results. Proper tools ensure:

- Accuracy: Precision cuts are crucial for the alignment and stability of the flooring.

- Efficiency: Good tools reduce the time spent on installation, translating to lower labor costs and quicker job completion.

- Safety: Using the right tools minimizes the risk of accidents and material damage.

- Cost-effectiveness: Correct tools reduce waste by minimizing material spoilage during cuts.

Overview of Vinyl, LVP, and Laminate Flooring Cutting Tools

When it comes to flooring installation, various types of cutters are used depending on the material:

Vinyl Floor Cutters: Designed for cutting vinyl flooring, these tools offer quick and clean cuts. The Roberts 10-94 Multi-Floor Cutter is a popular choice capable of handling vinyl, laminate, and even engineered wood up to 13 inches wide and 5/8 inches thick.

LVP Cutters (Luxury Vinyl Plank Cutters): These are used specifically for luxury vinyl planks. The Bullet Tools 9 inch EZ Shear Sharpshooter is a favored model for its ability to seamlessly cut through LVP, LVT, and more without the need for electricity.

Laminate Flooring Cutters: These are essential for anyone installing laminate flooring. Models like the Wolfcraft VLC 800 Cutter are praised for their sturdy design and the ability to produce clean, burr-free cuts.

| Tool Type | Best for Cutting | Popular Models |

|---|---|---|

| Vinyl Floor Cutters | Vinyl tiles and sheets | Roberts 10-94 Multi-Floor Cutter |

| LVP Cutters | Luxury Vinyl Tiles and Planks | Bullet Tools 9 inch EZ Shear Sharpshooter |

| Laminate Cutters | Laminate flooring | EAB Tool Exchange-a-Blade 2100005, Wolfcraft VLC 800 |

Using these specialized tools, installers can ensure that every piece fits perfectly, maintaining the integrity and beauty of the flooring material. Whether for a DIY project or professional installation, having the right cutter on hand is key to a successful, efficient, and safe flooring installation.

Products

Types of Flooring Cutters

Laminate Floor Cutters: Features and Benefits

Laminate flooring, due to its composition and design, requires specific cutting tools that can handle its unique material without chipping or splintering. Laminate floor cutters are engineered to offer precise, clean cuts with several benefits:

- Precision: Ensures each piece fits perfectly, essential for the floating floor setup.

- Clean Operation: Cuts without producing sawdust, keeping the workspace clean.

- Noise Reduction: Quieter than traditional saws, ideal for indoor use.

- Portability: Many models are lightweight and easy to transport.

Popular Models:

- EAB Tool Exchange-a-Blade 2100005 9-Inch Laminate Flooring Cutter: Best for its blade quality and ergonomic design.

- Wolfcraft VLC 800 Laminate Cutter: Renowned for its durability and ease of handling, making it a top choice for professionals.

Vinyl Plank Cutters: How They Work

Vinyl plank cutters are specialized tools designed to cut vinyl flooring efficiently. These cutters are crucial for achieving precise cuts that fit perfectly around corners and under door frames.

- Mechanism: Operate on a sharp blade system that slices through vinyl with minimal effort.

- Benefits: Produce clean cuts without rough edges, which prevents the flooring from tearing during installation.

Top Choices:

- Roberts 10-94 Multi-Floor Cutter: Can handle a variety of materials, including vinyl planks up to 13 inches wide.

- Bullet Tools 9 inch EZ Shear Sharpshooter Siding and Laminate Flooring Cutter: Offers a dust-free, quick, and precise cutting experience.

LVP Cutters vs. Laminate Cutters: Key Differences

While both LVP (Luxury Vinyl Plank) cutters and laminate cutters serve a similar function in flooring installation, their design and application differ significantly to cater to the specific materials they are intended for.

| Feature | LVP Cutter | Laminate Cutter |

|---|---|---|

| Material Suitability | Best for luxury vinyl tiles and planks | Optimized for the hardness of laminate materials |

| Cut Type | Slices through with a razor-sharp blade | Uses a guillotine-style blade for clean cuts |

| Result | Perfect for softer, flexible materials | Ideal for harder, brittle materials |

Example Products:

- Bullet Tools 9 inch EZ Shear Sharpshooter: A versatile tool for LVP and other soft flooring types.

- Wolfcraft VLC 800: Excellently handles the toughness of laminate without damage.

Flooring Guillotines: A Precise Cutting Option

Flooring guillotines provide a high level of precision and are particularly useful when you need to cut multiple pieces of flooring quickly and accurately.

- Operation: Operate with a sharp blade coming down in a guillotine-style to make fast, straight cuts.

- Advantages: Very efficient for both laminate and vinyl, offering quick, clean cuts with minimal waste.

Recommended Model:

- EAB Tool Exchange-a-Blade 2100005: Known for its precision and ability to handle various flooring types without adjustments.

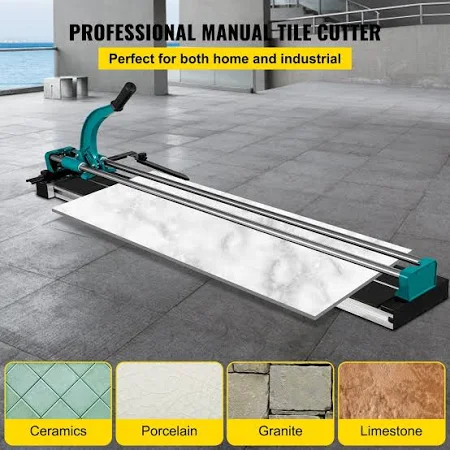

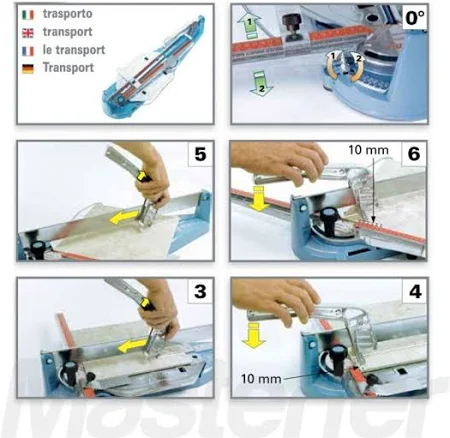

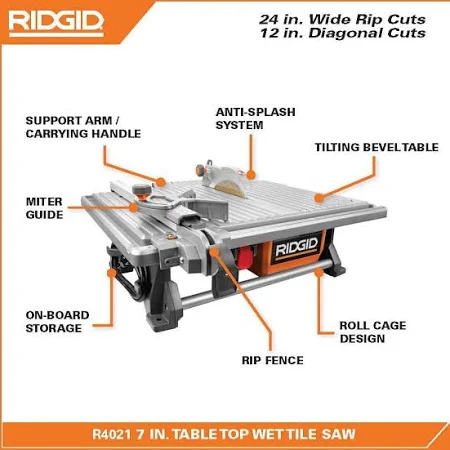

Tile Cutters for Vinyl Plank Flooring

When dealing with vinyl plank flooring, a tile cutter can be an unexpected but effective tool, especially for intricate cuts.

- Functionality: Designed to score and snap tile, but also works well for thin, resilient vinyl planks.

- Why Use Them: Offers an inexpensive and clean cutting solution for small projects.

Suggested Product:

- QEP 10630Q 24-Inch Manual Tile Cutter: Though primarily for ceramic and porcelain tiles, its precise scoring capability makes it suitable for vinyl planks too.

The above comprehensive guide to various types of flooring cutters ensures that whether you’re a DIY enthusiast or a professional installer, you have the knowledge to choose the right tool for your flooring project. Each type of cutter is tailored to specific materials, enhancing installation quality and efficiency.

Key Features to Look for in a Flooring Cutter

Blade Quality and Durability

When selecting a flooring cutter, the quality and durability of the blade are paramount. A high-quality blade ensures clean and precise cuts, reducing the risk of chipping or damaging the flooring material. Durability is crucial as it determines how often the blade will need to be replaced.

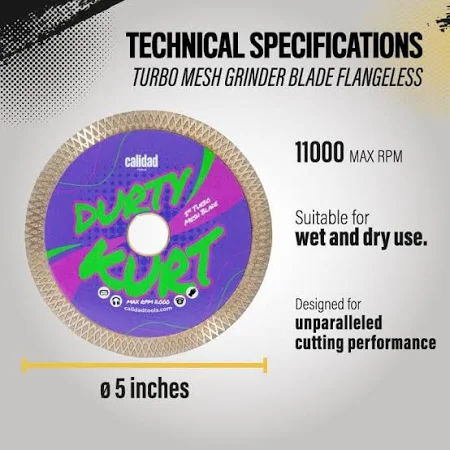

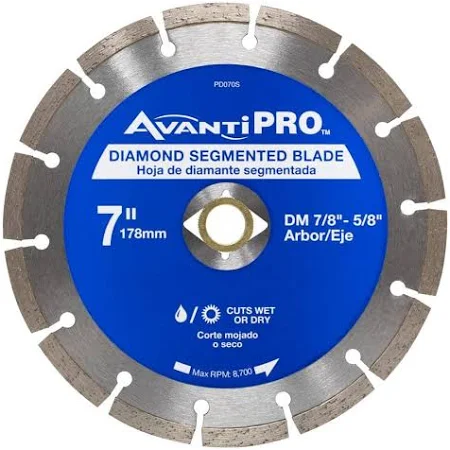

- Material: Look for blades made from tough materials like tungsten carbide or diamond-tipped edges, similar to those used in Diamond Blades for Grinders.

- Thickness and Sharpness: A thicker and sharper blade will handle dense materials like luxury vinyl tiles and high-pressure laminates more effectively.

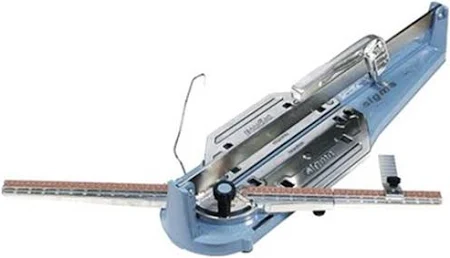

Cutter Precision for Laminate and Vinyl

Precision in cutting is vital for both aesthetic and functional fits, especially when working with laminate and vinyl flooring where edges are often exposed.

- Cutting Mechanism: A guillotine-style cutter, like the Sigma Tile Cutter 24 Inch, offers clean, straight cuts that are perfect for delicate materials.

- Adjustability: Features that allow for precise adjustments can help achieve the exact dimensions needed for installation, much like the precision needed when using a Large Format Tile Cutter.

Portability and Ease of Use

For professionals who work on various sites or DIY enthusiasts with limited space, the portability and ease of use of a flooring cutter are essential considerations.

- Weight and Size: Opt for lightweight and compact models such as the Hand Held Tile Cutter, which are easy to transport and store.

- Ergonomics: Ensure the cutter has a comfortable handle and a stable base for ease of operation, akin to the user-friendly design of the Ryobi Tile Cutter.

Versatility Across Flooring Types

A versatile flooring cutter can handle multiple types of materials, reducing the need for multiple tools and accommodating various project needs.

- Multi-Material Use: Some cutters are designed to handle various materials, from laminate to vinyl and even some types of tile. The VCT Tile Cutter is a good example, capable of cutting vinyl composite and luxury vinyl tiles.

- Blade Interchangeability: Tools like the MK Tile Saw allow for blade changes to cut different materials, making them ideal for projects that include both tile and laminate.

By focusing on these key features, buyers can ensure they choose a flooring cutter that will provide the performance and results needed for successful flooring installations. Whether using a specialized tool like the Brutus Tile Cutter for specific tile types or a more generalized cutter for various flooring materials, understanding these attributes helps in making an informed purchasing decision.

Top Flooring Cutters in 2024

Best Laminate Floor Cutters

Selecting the best laminate floor cutter requires understanding the specific needs of laminate flooring installations, such as precise cutting without chipping or splintering the material. In 2024, several models stand out for their efficiency, durability, and precision, catering to both professional installers and DIY enthusiasts.

Top Laminate Floor Cutters

EAB Tool Exchange-a-Blade 2100005 9-Inch Laminate Flooring Cutter

- Features: This cutter is designed for quick, precise cuts with a sturdy metal frame and extended handle to leverage cuts effortlessly.

- Advantages: It produces less dust compared to traditional saws, making it ideal for indoor use without requiring extensive cleanup.

- Ideal for: Homeowners looking for an easy-to-use tool for small to medium-sized projects.

Bullet Tools 13 in. EZ Shear Laminate Flooring Cutter for pergo, wood and more

- Features: Offers a longer blade life with a 13-inch cut width capability, perfect for various laminate plank sizes.

- Advantages: It does not produce any noise or require electricity, making it eco-friendly and suitable for use in any setting.

- Ideal for: Professionals needing a reliable tool that can handle multiple jobs without the need for blade replacements.

Roberts 10-64 Pro Flooring Cutter, 13-inch

- Features: This model is equipped with a sharp tungsten carbide blade ensuring clean, precise cuts. It also features a movable cutting guide for repeat cuts.

- Advantages: The cutter’s build includes an aluminum base for stability and rubber feet to prevent slippage.

- Ideal for: Larger projects that require frequent cuts, providing speed and consistency.

SKIL 3601-02 Flooring Saw with 36T Contractor Blade

- Features: Integrates both cutting and sawing capabilities, allowing users to rip, cross-cut, and miter laminate flooring.

- Advantages: It’s versatile and portable, combining the functions of a table saw and a laminate cutter.

- Ideal for: DIY enthusiasts and professionals looking for a versatile tool that eliminates the need for multiple tools on the job site.

Comparison Table for Laminate Floor Cutters

| Product Name | Cut Width | Dust Production | Power Requirement | Ideal Use |

|---|---|---|---|---|

| EAB Tool Exchange-a-Blade 2100005 | Up to 9 inches | Low | None | Small projects |

| Bullet Tools 13 in. EZ Shear | Up to 13 inches | None | None | Frequent use |

| Roberts 10-64 Pro Flooring Cutter | Up to 13 inches | Low | None | Large projects |

| SKIL 3601-02 Flooring Saw | Adjustable | Moderate | Electric | Versatile applications |

When considering a laminate floor cutter, it’s crucial to assess the specific needs of your project. Factors like the size of the area, the frequency of use, and the types of laminate being installed should influence your decision. Additionally, investing in a tool that aligns with your project’s complexity and budget can significantly affect the installation’s efficiency and outcome.

For detailed guidance on cutting specific types of tiles or enhancing your tool kit, explore resources such as How to Cut Tile for precision cutting tips, or Best Tile Cutter for Porcelain for tougher materials, ensuring your toolkit is as versatile and effective as possible for all your flooring projects.

Top Vinyl Plank Flooring Cutters

Selecting the right tool for cutting vinyl plank flooring is critical to ensuring smooth installation and optimal results. Here, we explore the best vinyl plank flooring cutters available in 2024, focusing on their functionality, efficiency, and ease of use.

Best Cutters for Vinyl Plank Flooring

1. Roberts 10-94 Multi-Floor Cutter

- Features: Capable of cutting vinyl planks, laminate, and engineered wood up to 13 inches wide and 5/8 inches thick.

- Advantages: Delivers quick, clean cuts with a durable blade and requires no electricity, which enhances portability.

- Ideal for: DIY projects and professional installations where multiple flooring types are used.

2. Bullet Tools EZ Shear Sharpshooter 9-Inch Flooring and Siding Cutter

- Features: Lightweight and easy to operate, designed to cut vinyl, laminate, and other siding materials.

- Advantages: Dust-free cutting ensures a cleaner work environment, and the device’s portability makes it suitable for both on-site and at-home use.

- Ideal for: Users looking for a hassle-free, efficient tool that supports various materials beyond vinyl planks.

3. Crain 673 13-Inch Vinyl Cutter

- Features: Engineered specifically for vinyl with a wide base for stability and a clear V-support to keep planks level while cutting.

- Advantages: Precision design minimizes waste and maximizes efficiency during the cutting process.

- Ideal for: Installers who need a reliable, precise cutter for large-scale vinyl plank installations.

Comparison Table for Vinyl Plank Flooring Cutters

| Cutter Model | Max Cut Width | Special Features | Ideal Usage |

|---|---|---|---|

| Roberts 10-94 Multi-Floor Cutter | Up to 13 inches | Multi-material capability, quick setup | Multi-floor installations |

| Bullet Tools EZ Shear Sharpshooter | Up to 9 inches | Lightweight, easy transport, no dust | Small to medium projects, various materials |

| Crain 673 13-Inch Vinyl Cutter | Up to 13 inches | Precision cutting, built specifically for vinyl | Professional vinyl installations |

Expert Recommendations

When choosing a cutter for vinyl plank flooring, consider the following tips to enhance your selection process:

- Check Compatibility: Ensure the cutter is suitable not just for vinyl planks but also for any other materials you plan to use.

- Assess Portability Needs: If the project involves multiple locations or constrained spaces, opt for a lightweight, easy-to-move cutter.

- Durability Matters: Choose cutters with robust construction and good warranties to ensure long-term use, especially in commercial settings.

Further Resources

For additional insights on cutting techniques and tool selections, refer to resources such as:

- How to Cut Tile for precision tips applicable to vinyl and laminate,

- Electric Tile Cutter for options that might be adapted for cutting thinner vinyl materials,

- Top 10 Best Tile Cutters for a broader perspective on available cutting tools that might suit various DIY needs.

By incorporating these guidelines and recommendations, you can choose the best vinyl plank flooring cutter that suits your project’s specific requirements, ensuring efficient, clean cuts and a professional finish. Whether for home renovations or larger commercial projects, the right cutter is an indispensable part of your toolkit.

Best Flooring Guillotines for Professionals

Flooring guillotines are essential tools for professionals seeking precise, clean cuts in various materials, including laminate and vinyl. These tools provide efficiency and accuracy, crucial for high-quality flooring installations. Here, we explore top flooring guillotines that stand out in 2024 due to their performance, reliability, and user-friendly features.

Top Flooring Guillotines on the Market

1. Bullet Tools 26 in. MAGNUM Flooring Shear

- Features: This cutter is designed to quickly and cleanly cut through laminate, engineered wood, and vinyl up to 26 inches wide.

- Advantages: Provides a quiet, dust-free operation with a movable fence for 45-degree (and up) cuts, enhancing versatility.

- Ideal for: Large commercial projects where speed and precision are paramount.

2. EAB Tool Exchange-a-Blade 2100005 9-Inch Laminate Flooring Cutter

- Features: Compact and highly efficient, this model is built with a durable steel and aluminum frame.

- Advantages: It offers a quick setup and a multi-purpose blade that can handle laminate and vinyl, providing clean cuts with minimal effort.

- Ideal for: Professionals and DIY enthusiasts who need a reliable tool for smaller, detailed projects.

3. Roberts 13″ Pro Flooring Cutter, Model 10-94

- Features: Known for its rugged build and sharp, precise cutting capabilities, this guillotine can handle materials up to 13 inches wide and 5/8 inch thick.

- Advantages: Features an extendable handle to reduce fatigue and a built-in ruler for quick measurements.

- Ideal for: Installers who require a durable, long-lasting tool that ensures accurate cuts every time.

Comparison Table for Flooring Guillotines

| Product Name | Max Cut Width | Material Compatibility | Key Features |

|---|---|---|---|

| Bullet Tools 26 in. MAGNUM Shear | 26 inches | Laminate, Vinyl, Engineered Wood | Movable fence for angled cuts, quick setup |

| EAB Tool 9-Inch Cutter | 9 inches | Laminate, Vinyl | Compact, easy to transport, multi-purpose |

| Roberts 13″ Pro Flooring Cutter | 13 inches | Laminate, Vinyl, Engineered Wood | Extendable handle, built-in ruler |

Expert Tips for Choosing a Flooring Guillotine

When selecting a flooring guillotine, consider the following tips to ensure you get the most suitable tool for your needs:

- Assess the Material Type: Choose a guillotine based on the types of materials you frequently work with. Models like the Bullet Tools MAGNUM Shear are perfect for thicker, wider materials.

- Consider Portability: If you frequently move between job sites, consider lightweight and compact models like the EAB Tool 9-Inch Cutter.

- Durability: Opt for guillotines with sturdy construction and reliable blades to withstand frequent use, especially in commercial settings.

Further Resources for Flooring Professionals

For those looking to expand their expertise or explore additional tools, consider visiting:

- How to Cut Tile for precision cutting tips,

- Electric Tile Cutter for tools that offer clean, precise cuts in ceramic and porcelain,

- Ryobi Tile Cutter for a versatile option suitable for various tile types.

By leveraging the right flooring guillotine, professionals can enhance their operational efficiency, ensuring precise cuts and high-quality installations. Whether working on residential or commercial projects, the appropriate tools are pivotal in achieving optimal results and client satisfaction.

Affordable Options for DIY Enthusiasts

DIY enthusiasts often seek tools that provide the best balance between cost and functionality. Here, we explore some affordable options for cutting tools that are perfect for do-it-yourself projects involving laminate, vinyl, and even wood flooring. These selections cater to those who need reliable performance without breaking the bank.

Top Budget-Friendly Flooring Cutters

1. SKIL 3601-02 Flooring Saw with 36T Contractor Blade

- Features: Combines the capabilities of both a standard miter and a table saw, enabling cross, miter, and rip cuts in materials like laminate and engineered wood.

- Advantages: Compact and easy to set up with a price point that appeals to DIYers.

- Price Range: Under $200

- Ideal for: Those looking for a versatile, space-saving tool capable of making a variety of cuts.

2. Wolfcraft VLC 800 Vinyl and Laminate Cutter

- Features: Specifically designed for cutting laminate up to 11 mm thick and vinyl up to 6 mm thick.

- Advantages: Provides precise, clean cuts with minimal effort and no electricity required.

- Price Range: Under $100

- Ideal for: DIYers needing a straightforward, easy-to-use tool for laminate and vinyl.

3. Norge 10-35 Laminate Cutter

- Features: A simple, manually operated cutter that handles laminate up to 8 inches wide.

- Advantages: Extremely budget-friendly and portable, with a lightweight design.

- Price Range: Under $50

- Ideal for: Beginners and those with occasional small home projects.

Comparison Table for Budget-Friendly Flooring Cutters

| Cutter Model | Max Cut Width | Material Compatibility | Price Range | Ideal Usage |

|---|---|---|---|---|

| SKIL 3601-02 Flooring Saw | Varies | Laminate, Engineered Wood | Under $200 | Versatile cutting |

| Wolfcraft VLC 800 Cutter | Up to 11 mm thick | Laminate, Vinyl | Under $100 | Simple, precise cuts |

| Norge 10-35 Laminate Cutter | Up to 8 inches | Laminate | Under $50 | Small projects, beginners |

Why Choose Affordable Tools?

For DIY enthusiasts, investing in affordable tools means:

- Cost Efficiency: Saving money on tools allows for allocation of funds to higher quality flooring materials or other aspects of a project.

- Learning Curve: Affordable tools often come with user-friendly features ideal for beginners.

- Flexibility: Lower investment risk makes it easier to explore different types of flooring projects without commitment to expensive equipment.

Additional Resources

For those looking to expand their DIY skills or learn more about specific types of cutting projects, consider the following resources:

- How to Cut Tile provides essential tips for handling ceramic or porcelain with precision.

- Electric Tile Cutter for those projects that require smooth, continuous cuts in tile.

- Top 10 Best Tile Cutters to compare a variety of tools that could enhance your toolkit’s versatility.

These affordable options ensure that DIY enthusiasts can undertake various home flooring projects with confidence and success, equipped with the right tools that offer both quality and value.

Comparisons and Reviews: Laminate vs. Vinyl Flooring Cutters

When embarking on a flooring project, choosing the right tool for the job is paramount. For DIY enthusiasts and professionals alike, the decision often comes down to selecting between laminate and vinyl flooring cutters. Each type of cutter has its own set of features that cater to specific materials and needs. This comparison will help clarify which cutter might be better suited for your flooring projects.

Laminate Flooring Cutters

Laminate flooring cutters are designed to handle the dense and rigid structure of laminate materials. Here’s why they might be the right choice:

- Precision Cutting: Provides clean, precise cuts with minimal chipping, crucial for the aesthetics of laminate flooring.

- Dust-Free Operation: Unlike saws, these cutters do not produce a significant amount of dust, making them ideal for indoor use.

- Ease of Use: Generally, these cutters are manually operated and require less technical skill, which is great for DIY projects.

Top Products:

- EAB Tool Exchange-a-Blade 2100005: Known for its precision and durability.

- Wolfcraft VLC 800: Offers an easy-to-use lever mechanism and can handle various thicknesses of laminate.

Vinyl Flooring Cutters

Vinyl cutters are tailored for cutting vinyl plank, tile, and sometimes even luxury vinyl tile (LVT), which are softer than laminate.

- Versatility: Many vinyl cutters can handle different types of flooring materials, including LVT and some thin carpets.

- Speed: These cutters can slice through vinyl quickly, which is advantageous when working on large areas.

- Portable and Compact: Typically lighter than laminate cutters, making them easy to move and store.

Top Products:

- Roberts 10-94 Multi-Floor Cutter: Capable of cutting a wide range of materials up to 13 inches wide.

- Bullet Tools 9 inch EZ Shear Sharpshooter: A versatile, dust-free cutter perfect for vinyl and other soft materials.

Feature Comparison Table

| Feature | Laminate Cutter | Vinyl Cutter |

|---|---|---|

| Best For | Dense, rigid materials | Softer, flexible materials |

| Cutting Action | Guillotine-type blade | Sharp blade or shear action |

| Dust Production | Minimal | Minimal to none |

| Typical Use | DIY home projects, professional installations | Quick jobs, multi-floor installations |

| Portability | Moderate | High |

| Price Range | Generally higher due to robust construction | More affordable, varies by capacity and features |

Which is Better?

The choice between a laminate and a vinyl flooring cutter depends largely on the material you plan to cut most frequently.

- For Laminate: If precision and clean edges are crucial, and you are primarily working with laminate, a dedicated laminate flooring cutter like the EAB Tool Exchange-a-Blade 2100005 is advisable.

- For Vinyl and Multi-Materials: If you need a cutter that offers flexibility to handle various types of flooring materials, including vinyl, LVT, and even some carpets, then a multi-material cutter like the Roberts 10-94 might be the better option.

Before purchasing, consider the scale of your projects, the types of materials you’ll be working with most often, and your budget. For more specialized tasks, such as cutting tiles or handling porcelain, exploring tools designed for those materials, like a Sigma Tile Cutter 24 Inch or a Wet Saw Tile Cutters, might also be necessary. By aligning the cutter’s capabilities with the specific needs of your flooring projects, you ensure efficient work and beautiful results.

Comparisons and Reviews: Prowler vs. Mantistol Flooring Cutters

When it comes to professional flooring installation, choosing the right tools can make a significant difference in the quality and efficiency of your work. Two popular models in the market are the Prowler and Mantistol flooring cutters. Both are renowned for their robust performance, but they cater to slightly different needs and preferences. Here’s a detailed comparison to help determine which might be better suited for your specific project requirements.

Prowler Flooring Cutters

Key Features and Benefits:

- Design and Build: Prowler cutters are generally robust and designed for heavy-duty use. They often feature a sturdy construction that can handle various types of flooring materials.

- Cutting Capacity: Ideal for cutting thicker and wider materials, making them suitable for large-scale commercial projects.

- Precision: Known for precise cuts that are essential for seamless installation, especially in complex patterns and layouts.

Popular Models:

- Prowler 12in. Laminate and Vinyl Floor Cutter: Specifically designed to offer precise cuts in both laminate and vinyl plank materials.

Pros:

- High durability suitable for continuous, heavy use.

- Enhanced precision for complex cuts.

- Wide cutting width capacity.

Cons:

- Generally more expensive due to high build quality.

- Heavier, which may affect portability.

Mantistol Flooring Cutters

Key Features and Benefits:

- Versatility: Mantistol cutters are versatile, capable of handling a variety of flooring materials, including laminate, vinyl, and sometimes even soft wood.

- User-Friendliness: These cutters are designed with the user in mind, featuring easy-to-handle mechanisms and lighter builds for better portability.

- Cost-Effectiveness: They offer a great balance between performance and price, making them ideal for both professionals and DIY enthusiasts.

Popular Models:

- Mantistol LVT-330 13-inch Heavy Duty Floor Cutter: Best for LVT, PVC, LVP, WPC, Rigid Core Vinyl Plank, and more, providing clean cuts with minimal effort.

Pros:

- Great versatility to handle different materials.

- More affordable, offering good value for money.

- Lighter and more portable for various job site needs.

Cons:

- May not handle very thick or hard materials as effectively as heavier-duty models.

- Durability may be less compared to more robust cutters like the Prowler.

Comparison Table: Prowler vs. Mantistol

| Feature | Prowler Flooring Cutter | Mantistol Flooring Cutter |

|---|---|---|

| Ideal for | Commercial projects, heavy-duty use | Versatile home use, light commercial projects |

| Material Capability | Laminate, vinyl, some engineered woods | Laminate, LVT, vinyl, PVC, some soft woods |

| Weight | Heavier, less portable | Lighter, more portable |

| Price Point | Higher, due to durable construction | More affordable, great for budget-conscious users |

| Ease of Use | Optimal for experienced users | User-friendly for all skill levels |

Which is Better?

The choice between Prowler and Mantistol flooring cutters depends largely on your specific needs:

- Choose Prowler if you require a durable tool for heavy-duty, frequent use, especially in commercial settings where precision and the ability to handle tough materials are paramount.

- Opt for Mantistol if you seek a more versatile, cost-effective tool for a range of projects, including DIY and light commercial work where ease of transport and varied material cutting are necessary.

Both brands offer distinct advantages, and the best choice will align with the demands of your specific flooring projects. For further insights and detailed product reviews, exploring specialized resources and user testimonials can provide additional guidance to ensure you invest in the right tool for your flooring installation needs.

Luxury Vinyl Plank (LVP) Cutters: Top Brands Reviewed

Luxury Vinyl Plank (LVP) flooring has surged in popularity due to its durability and aesthetic appeal, resembling hardwood without the extensive maintenance. Cutting LVP requires precision tools that ensure clean, swift cuts without damaging the material. Here, we review some of the top brands in LVP cutters, focusing on their performance, ease of use, and suitability for various project sizes.

Top LVP Cutter Brands

1. Bullet Tools EZ Shear Sharpshooter

- Key Features: Designed to cut LVP, laminate, and other flooring types up to 9 inches wide and ⅝ inches thick without producing dust.

- Benefits:

- Dust-Free Cuts: Ideal for indoor settings where cleanliness is a priority.

- Portable: Lightweight design makes it easy to transport between job sites.

- Best For: DIY enthusiasts and professionals needing a versatile, clean-cutting tool for smaller projects.

2. Roberts 10-94 Multi-Floor Cutter

- Key Features: Can handle materials up to 13 inches wide, including LVP, laminate, and engineered wood.

- Benefits:

- Multi-Material Use: Versatile enough for various flooring types.

- Extended Handle: Reduces effort, enhancing user comfort during prolonged use.

- Best For: Professionals working on large-scale residential or commercial projects.

3. Crain 673 13-Inch Vinyl Cutter

- Key Features: Specifically tailored for vinyl flooring, this cutter provides precise cuts up to 13 inches wide.

- Benefits:

- Built-in Measuring Gauge: Ensures accurate cuts.

- Rigid Design: Offers stability and durability.

- Best For: High-volume cutting environments where precision is critical.

Comparison Overview

| Brand | Cut Width | Material Suitability | Unique Feature |

|---|---|---|---|

| Bullet Tools | Up to 9 inches | LVP, Laminate | Dust-free operation |

| Roberts | Up to 13 inches | LVP, Laminate, Engineered Wood | Multi-floor capabilities |

| Crain | Up to 13 inches | Vinyl Only | Precision with measuring gauge |

Choosing the Right LVP Cutter

Selecting the right LVP cutter depends on several factors:

- Project Size: Larger projects might benefit from a cutter like the Roberts 10-94 for its wide cut and versatility, whereas smaller, DIY projects might be better suited to the compact and clean-cutting Bullet Tools Sharpshooter.

- Material Types: If working exclusively with vinyl, the Crain 673 offers specialized cutting precision. For varied materials, a more versatile cutter like the Roberts would be advantageous.

- Budget Constraints: Bullet Tools cutters tend to be more affordable and are a great entry point for less frequent use without sacrificing quality.

For those looking to deepen their understanding of flooring installation or explore further into specialized cutting tools, additional resources can be immensely helpful:

- How to Cut Tile provides general cutting tips that can be adapted for precision tasks.

- Electric Tile Cutter explores tools that might be overkill for LVP but useful for harder materials.

- Top 10 Best Tile Cutters offers a broader look at cutting tools that might be applicable for more complex or diverse flooring projects.

Choosing the right LVP cutter will not only affect the ease of your installation but also the finished look and durability of the flooring. With the right tool, even the most challenging cuts can be made efficiently, ensuring a professional finish every time.

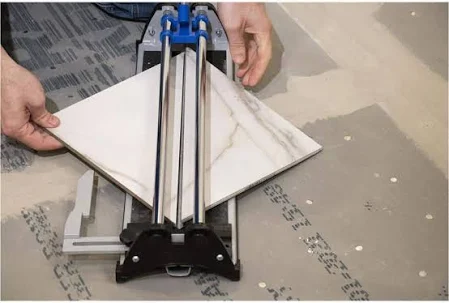

How to Use a Laminate Floor Cutter Safely

Using a laminate floor cutter is an essential skill for anyone involved in flooring installation, especially when working with laminate materials. Laminate floor cutters are designed to offer a clean, efficient, and precise cut, reducing waste and ensuring that the panels fit perfectly. Here’s a detailed guide on how to use a laminate floor cutter safely and effectively.

Preparation and Setup

Choose the Right Cutter: Ensure the laminate floor cutter is suitable for the type of laminate you are cutting. Models like the EAB Tool Exchange-a-Blade 2100005 9-Inch Laminate Flooring Cutter are highly recommended for their precision and durability.

Set Up Your Work Area:

- Stable Surface: Place the cutter on a stable, flat surface. Avoid uneven grounds to prevent inaccurate cuts or potential accidents.

- Space Clearance: Ensure there is ample space around the cutter for easy movement and handling of laminate planks.

Safety Gear:

- Eye Protection: Always wear safety goggles to protect your eyes from small particles.

- Gloves: Use gloves to protect your hands from sharp edges and to enhance grip.

Measuring and Marking

- Measure Twice, Cut Once: Before making any cuts, measure the laminate plank accurately and mark the cutting line with a pencil or chalk. Use a T-square or a ruler to ensure the line is straight.

Cutting Process

Positioning the Plank:

- Place the laminate plank firmly against the cutter’s backrest to ensure it is perfectly aligned with the blade.

- Hold the plank securely to prevent any movement during the cutting process.

Engaging the Cutter:

- Lower the cutting handle smoothly and apply steady pressure until the blade slices through the laminate. Do not rush this step; a controlled motion ensures a cleaner cut.

Completing the Cut:

- Once the cut is complete, lift the handle back to its starting position and carefully remove the cut piece from the cutter.

Repeat as Needed: Continue measuring, marking, and cutting the remaining planks according to your project’s layout.

Maintenance and Care

- Blade Sharpness: Regularly check the sharpness of the blade. A dull blade can result in jagged cuts and may damage the laminate material.

- Cleaning: Keep the cutter clean from dust and debris. Wipe the blade with a dry cloth after each use to maintain its effectiveness and longevity.

Safety Tips

- Never Force the Cutter: If you feel resistance while cutting, do not force the handle. Check if the blade is dull or if the plank is not positioned correctly.

- Be Mindful of Hands and Fingers: Always keep your hands and fingers away from the cutting area to avoid injuries.

- Secure the Cutter: Ensure the cutter is securely placed on a non-slip surface to prevent any movement during operation.

Troubleshooting Common Issues

- Chipping: If chipping occurs, it might be due to a dull blade or excessive force. Ensure the blade is sharp and that you are applying steady, controlled pressure.

- Misalignment: Double-check the alignment of the plank before cutting. Misaligned planks can lead to inaccurate cuts.

By following these detailed steps, you can maximize the efficiency of your laminate floor cutter and ensure that your flooring installation proceeds smoothly and safely. For additional resources or specific product recommendations, such as the EAB Tool Exchange-a-Blade 2100005, always refer to trusted sources or professional guides.

Cutting Vinyl Plank Flooring Lengthwise: Step-by-Step Guide

Cutting vinyl plank flooring (LVP) lengthwise requires precision to ensure the planks fit perfectly without wasting material. This guide outlines the steps and considerations for effectively slicing vinyl plank flooring using the right tools and techniques.

Choosing the Right Tool

- Select an Appropriate Cutter:

- Vinyl Plank Cutters: For clean and precise cuts, specialized vinyl plank cutters like the Roberts 10-94 Multi-Floor Cutter are recommended.

- Utility Knife: For a more manual approach or finer cuts, a sharp utility knife can be effective, especially for trimming to fit around corners or edges.

Preparation

- Measure Accurately: Before making any cuts, measure the area where the plank will be placed. Use a tape measure to determine the length needed and mark this measurement on the plank using a pencil.

- Secure the Workspace: Ensure your work surface is stable and that the vinyl plank is securely clamped down, preventing any movement during cutting.

Cutting Process

Marking the Plank:

- Draw a straight line along the length of the plank where the cut is needed using a straight edge or a carpenter’s square to ensure accuracy.

Using a Vinyl Plank Cutter:

- Place the vinyl plank in the cutter aligning the blade with the marked line.

- Press down on the cutter handle firmly and evenly until the plank is sliced through. This method is quick and yields very clean cuts.

Using a Utility Knife:

- If using a utility knife, place a straight edge along the marked line for guidance.

- Score the surface of the vinyl gently with the knife, then increase pressure on subsequent passes to deepen the cut until the plank can be snapped along the scored line.

Finishing the Cut:

- For rough edges or small imperfections, use a file or sandpaper to smooth out the cut edge, ensuring it will fit snugly and not cause issues during installation.

Safety Tips

- Wear Protective Gear: Always wear safety glasses to protect your eyes from flying particles. Using gloves can also protect your hands during the cutting process.

- Handle Blades Carefully: Change blades regularly to maintain sharpness and ensure clean cuts, handling them with care to avoid injury.

Maintenance of Tools

- Keep Cutting Tools Sharp: Regularly check and replace the blades in your cutters or knives to make the cutting process easier and safer.

- Clean Your Tools After Use: Remove any adhesive or remnants from blades and cutting surfaces to keep them in good condition.

Troubleshooting Common Issues

- Chipped or Frayed Edges: If edges chip or fray, it may indicate a dull blade. Replace your blade or try a different cutting method.

- Measurement Mistakes: Double-check measurements before cutting, as incorrect measurements can lead to wasted material and additional costs.

Using the proper tools and techniques is crucial when cutting vinyl plank flooring lengthwise. Whether using a specialized vinyl plank cutter for larger projects or a utility knife for smaller, precision cuts, the key is to work with care and precision. Remember, thorough preparation and accurate measuring go a long way in ensuring that your flooring cuts are perfect for your installation needs.

Tips for Cutting Luxury Vinyl Tile (LVT)

Cutting Luxury Vinyl Tile (LVT) requires precision and the right tools to ensure clean, straight cuts that fit perfectly in your designated space. LVT is a popular flooring option due to its durability and the variety of designs available. Here are some essential tips and techniques to help you cut LVT effectively:

Choosing the Right Tools

Types of Cutters:

- LVT Cutters: Specialized tools like the Roberts 12-960 LVT Cutter are designed to handle the specific thickness and material properties of LVT.

- Utility Knives: For smaller or more intricate cuts, a sharp utility knife can be very effective.

- Vinyl Tile Cutters: These provide fast and straightforward cuts with models like the Crain 001 Model “A” Vinyl Tile Cutter offering precise performance.

Measuring Equipment:

- Ensure you have a reliable tape measure and a straight edge or T-square for accurate measurement and alignment.

Preparation Steps

- Measure and Mark: Carefully measure the area where the tile will be placed. Use a pencil or a non-permanent marker to lightly mark where the cuts should be made on the LVT surface.

- Secure the Tile: Secure the LVT on a cutting surface to prevent it from moving. Use clamps if necessary, especially for larger pieces.

Cutting Techniques

Straight Cuts:

- Position your straight edge along the line where the cut is to be made.

- Run the utility knife or floor cutter along the straight edge, applying consistent pressure to score the tile. Depending on the thickness, several passes may be required.

- Bend the tile gently along the score line to snap it neatly.

Complex Cuts:

- For cuts around obstacles or irregular shapes, create a template out of cardboard to trace the shape onto the tile.

- Carefully cut along the traced lines using a utility knife, making several gentle passes to achieve a clean cut.

Safety Tips

- Wear Protective Gear: Always wear safety goggles and gloves to protect against sharp edges and debris.

- Keep Your Work Area Clean: Regularly clear away any LVT scraps or dust to maintain a safe working environment.

Post-Cutting

- Smooth Edges: After cutting the LVT, you might find slight burrs or rough edges. Use a fine-grit sandpaper to smooth these out.

- Check Fit Regularly: After each cut, check how the tile fits in its intended location. It’s easier to trim a little more off than to deal with a tile that’s been cut too short.

Maintaining Your Cutting Tools

- Blade Care: Regularly replace or sharpen the blades of your cutters to ensure they are always ready for a clean cut.

- Clean After Use: Clean your tools after each use to prevent adhesive build-up from the vinyl, which can hinder performance.

Troubleshooting Common Cutting Issues

- Chipping or Splitting: If the LVT chips or splits during cutting, it may be due to a dull blade or excessive force. Ensure your cutting tools are sharp and that you’re applying even, moderate pressure.

- Misalignment: Always double-check your measurements and the alignment of your cutting guide before making a cut to avoid mistakes.

By following these guidelines, you can achieve professional-quality cuts on your LVT flooring, ensuring a beautiful finish. For additional resources or specific product suggestions, visiting links such as How to Cut Tile can provide more detailed insights into similar materials and cutting techniques.

Common Mistakes When Using Flooring Cutters

Using a flooring cutter is essential for precise and efficient flooring installation, especially when working with materials like laminate, vinyl, and luxury vinyl tile (LVT). However, even seasoned professionals can make mistakes that affect the quality of the installation and waste material. Here’s a detailed look at common errors and how to avoid them.

Mistake #1: Using Dull Blades

- Impact: Dull blades can cause jagged cuts, damage to the material, and increased physical effort.

- Prevention: Regularly check and replace the blades on your cutters. For products like the Roberts 10-91 Multi-Floor Cutter, replacement blades are readily available and easy to install.

Mistake #2: Incorrect Measurement and Cutting

- Impact: Misalignment and gaps in the installed flooring due to inaccurate cuts.

- Prevention:

- Always measure twice before cutting.

- Use precision tools like a laser measure or a traditional tape measure for accuracy.

Mistake #3: Not Using the Correct Cutter for the Material

- Impact: Poorly executed cuts that can compromise the installation.

- Prevention:

- Use the appropriate cutter for the type of flooring. For instance, a vinyl floor cutter should be used for vinyl products, not for thicker materials like laminate.

- Research and follow manufacturer recommendations for specific flooring materials.

Mistake #4: Improper Handling and Operation

- Impact: Safety risks and poor quality cuts.

- Prevention:

- Familiarize yourself with the flooring cutter’s manual before use.

- Ensure that all safety features, such as guards and locks, are used correctly.

Mistake #5: Failing to Secure the Flooring Material

- Impact: Slippage during cutting, leading to uneven cuts.

- Prevention:

- Use clamps or grips to secure the material firmly in place during the cutting process.

- Ensure your work surface is stable and non-slip.

Mistake #6: Rushing the Cutting Process

- Impact: Increases the likelihood of mistakes and accidents.

- Prevention:

- Take your time with each cut to ensure precision.

- Plan your cuts in advance to minimize haste.

Mistake #7: Not Maintaining the Cutter

- Impact: Poor performance and potential damage to the flooring material.

- Prevention:

- Regularly clean and maintain your cutter according to the manufacturer’s instructions.

- Check for loose components and lubricate moving parts as necessary.

Avoiding These Mistakes

To avoid these common errors, invest in high-quality cutting tools like the Roberts 10-94 Multi-Floor Cutter or the EAB Tool Exchange-a-Blade 2100005 9-Inch Laminate Flooring Cutter. These tools are designed to handle different flooring materials and thicknesses with precision.

Additional Resources

For more detailed guidance on choosing and using flooring cutters, consider exploring:

- How to Cut Tile for tips on cutting ceramic or porcelain tiles.

- Electric Tile Cutter for information on handling more robust materials.

- Top 10 Best Tile Cutters for reviews on the latest tools in the market.

By being aware of and avoiding these common mistakes, you can ensure a smoother and more professional flooring installation process.

Maintaining Your Flooring Cutter for Longevity

Proper maintenance of your flooring cutter is crucial for ensuring it performs effectively and lasts through many projects. Whether you are working with laminate, vinyl, or luxury vinyl tile (LVT), keeping your cutter in top condition will result in cleaner cuts and a more professional finish. Here’s how to maintain your flooring cutter to enhance its longevity and performance.

Routine Maintenance Steps

Cleaning After Use: Always clean your cutter after each use. Remove all debris, dust, and small particles from the cutting area, blades, and moving parts. This prevents buildup that can affect the cutter’s performance. For instance, a laminate floor cutter should be wiped down to remove any laminate shards that could impede the blade’s movement.

Lubrication: Regularly lubricate the moving parts of the cutter to ensure smooth operation. Use a light machine oil on joints and pivot points to reduce friction and wear. Check the manufacturer’s manual for specific lubrication points and recommended oils.

Blade Inspection and Replacement: Inspect the cutting blades regularly for signs of wear or damage. Replace the blades as needed to keep cuts clean and precise. Keeping a replacement blade like the EAB Tool Exchange-a-Blade 2100005 on hand ensures you can switch out blades as soon as the need arises.

Check for Loose Components: Before and after use, check for any loose screws, bolts, or fittings and tighten them as necessary. This ensures the cutter remains stable and accurate during operation.

Storage: Store your flooring cutter in a clean, dry place to avoid rust and corrosion. Cover it to protect against dust and moisture. Proper storage extends the life of the tool and keeps it ready for the next job.

Advanced Maintenance Tips

Alignment Checks: Periodically check the alignment of the cutting blade and the base. Misalignment can lead to uneven cuts or increased wear on the cutter. Adjust according to the manufacturer’s guidelines.

Replace Wear Parts: Besides blades, other parts like the cutting board or the handle grips may wear out and need replacement. Keep an eye on these components, especially if you notice a decline in performance or comfort during use.

Professional Servicing: For high-end models, such as the Roberts 10-94 Multi-Floor Cutter, consider professional servicing if you encounter any complex issues. Professional maintenance can help diagnose and fix problems that are not obvious to the untrained eye.

Handling and Usage Tips

Use According to Specifications: Only use the flooring cutter for its intended range of materials and thicknesses. For example, do not attempt to cut materials thicker than what is recommended for your vinyl plank cutter, as this can strain the cutter and cause premature wear.

Operate with Care: Always use steady, controlled pressure when cutting. Forcing the cutter can bend the blade or damage the mechanism.

Preventing Common Issues

Avoid Rust: If your cutter is susceptible to rust (especially in humid environments), occasionally wipe it down with an oil-soaked rag to keep the metal parts protected.

Sharpness Check: Keep blades sharp to avoid inefficient cuts that can strain the cutter’s motor (if motorized) or mechanisms. A sharp blade ensures quick, effortless cuts.

By following these maintenance tips, your flooring cutter will remain a reliable tool in your flooring installation arsenal for years to come. This not only ensures efficiency and accuracy in your work but also safeguards your investment in quality tools.

For specific product maintenance, refer to resources like How to Grout Tile for additional care instructions related to tile cutting tools, which share common maintenance protocols with laminate and vinyl cutters.

Tools and Accessories for Flooring Projects

When tackling DIY flooring projects, having the right tools can make all the difference between a professional-looking finish and a potential redo. Here’s a comprehensive guide to the essential tools and accessories for cutting and installing various types of flooring, from vinyl planks to laminate.

Best Vinyl Flooring Cutting Tools for DIY Projects

For those looking to handle vinyl flooring installations themselves, certain tools are indispensable for achieving clean, precise cuts:

Vinyl Plank Cutters: Tools like the Bullet Tools EZ Shear Sharpshooter are ideal for quickly and cleanly cutting vinyl plank flooring. Its blade is designed to slice through vinyl with minimal dust and no electricity required.

Utility Knives: A simple but essential tool. For intricate cuts around corners or obstacles, a good quality utility knife with replaceable blades, such as the Stanley FatMax, is a must-have.

Vinyl Tile Cutters: For those working with vinyl tile rather than planks, a dedicated vinyl tile cutter can provide more precise cuts than scissors or a utility knife.

Essential Tools for Cutting Around Door Frames and Trims

Cutting around door frames requires precision to ensure that flooring fits snugly and looks professionally installed:

Jamb Saws: These are used to trim the bottom of door casings to allow the new floor to slide underneath. The Roberts Long Neck Jamb Saw is particularly effective for this purpose.

Oscillating Multi-Tools: A versatile tool that can be equipped with various blades, an oscillating tool like the DeWalt DCS355B allows for precise cuts in tight spaces, which is ideal for door frames and trims.

Must-Have Flooring Installation Kits

To make your flooring project smoother and ensure you have all the necessary tools at hand, consider investing in a comprehensive flooring installation kit. Such kits typically include:

- Spacers: To maintain a consistent expansion gap around the room edges.

- Tapping Block: To protect the edges of the planks when tapping them into place.

- Pull Bar: For pulling planks together in tight areas near walls where a tapping block can’t be used.

- Knee Pads: Essential for comfort when installing flooring over large areas.

An example of a well-rounded kit is the Roberts Pro Flooring Installation Kit, which includes all the above tools in one convenient package.

Tool Care and Maintenance

To extend the life of your flooring tools, regular maintenance is crucial:

- Regular Cleaning: Remove dust and adhesive residue after each use.

- Blade Replacement: Keep cutting tools sharp by replacing blades regularly; dull blades can damage materials and make your work harder.

- Proper Storage: Store tools in a clean, dry place to prevent rust and damage.

With the right set of tools, a DIY flooring project can be completed efficiently and with high-quality results. Investing in quality tools not only ensures the longevity of the tools themselves but also the success of your installation.

For more information on specific cutting tools and their uses, consider visiting How to Cut Tile for detailed guidance on tile cutting techniques which can also be applicable to some types of flooring cuts. Additionally, Electric Tile Cutters provide a more in-depth look at tools suitable for precision cutting of harder materials.

FAQs

Can I use a tile cutter for laminate?

No, a typical manual tile cutter is not suitable for cutting laminate flooring as it works through a scoring and snapping action, suitable for brittle materials like ceramic. Laminate requires a different type of cutting action because it is a wood composite that can splinter or chip.

How do you cut laminate tile?

Laminate tiles can be cut with a laminate cutter, which is designed to handle the composite nature of the tiles. Alternatively, for more intricate cuts, a power saw with a fine-tooth blade like a jigsaw or a circular saw can be used.

What is the best tool to cut laminate flooring with?

The best tool for straight cuts in laminate flooring is a power miter saw equipped with a fine-tooth blade. For more detailed cuts, such as curves or notches, a jigsaw with a laminate cutting blade is ideal.

What is the best thing for cutting laminate flooring?

A table saw or a power miter saw with a high-quality, fine-tooth blade designed for laminate flooring, such as the Freud D1084L, ensures clean, precise cuts.

Can you tile directly over laminate?

It is not recommended to tile directly over laminate flooring. Laminate is not a stable enough base for tile; it can expand and contract, leading to cracking in the tile. It’s best to remove the laminate and prepare the subfloor properly.

How to stop laminate chipping when cutting?

To prevent chipping when cutting laminate:

- Use a sharp blade specifically designed for laminate.

- Cut the laminate with the finish side down if using a circular saw or with the finish side up if using a jigsaw.

- Apply tape over the cut line to further reduce splintering.

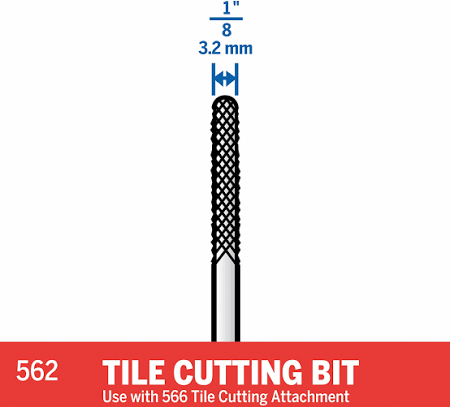

Can you use a Dremel to cut laminate flooring?

Yes, a Dremel can be used for cutting laminate flooring, especially for intricate cuts. Use a Dremel with a multi-purpose cutting bit or an appropriate cutting wheel.

How do you cut laminate tile around a toilet?

Measure and mark the cut line on the laminate tile. Use a jigsaw with a fine-tooth blade to cut curves and notches to fit around the toilet base. Test fit and trim as needed for a precise fit.

Can I cut laminate flooring with a utility knife?

While it’s possible to score and snap thin laminate using a utility knife, it’s generally not recommended for thicker or high-quality laminate. A cutter or saw ensures cleaner cuts and is more efficient for larger projects.

Is there a special blade to cut laminate flooring?

Yes, use a blade specifically designed for cutting laminate, such as blades with diamond or carbide tips. These blades minimize chipping and extend the life of your saw due to the hard, abrasive nature of laminate.

How do you cut laminate flooring without chipping it?

To cut laminate without chipping:

- Use a sharp blade designed for laminate.

- Cut slowly and steadily.

- Support the plank fully near the cut to reduce vibrations.

Do you cut laminate flooring face up or down?

When using a circular saw, cut laminate flooring face down to minimize chipping. When using a jigsaw or a hand saw, cut it face up.

How to fix horizontal gaps in laminate flooring?

To fix horizontal gaps:

- Ensure the floor is clean and debris-free.

- Use a floor gap fixer tool or a tapping block to gently tap the planks back into place.

- For persistent gaps, consider using a laminate floor glue in the groove of the plank, then slide it back into place and wipe off excess glue.

How to lay laminate flooring around corners?

To lay laminate around corners, measure and mark the planks for cutting. Use a miter saw for angled cuts or a jigsaw for curved cuts. Always dry-fit your cuts to ensure accuracy before final placement.

Can you use a multi-tool to cut laminate flooring?

Yes, a multi-tool can be very effective for making plunge cuts and cutting laminate flooring where other saws might not reach. Use a blade designed for wood or laminate.

Do you need underlayment for laminate flooring over tile?

Yes, using an underlayment over tile before laying laminate flooring is essential for several reasons: it can smooth out minor imperfections, provide a moisture barrier, and add sound dampening.

What do you put between laminate and tile?

A transition strip should be used between laminate and tile. This not only covers the expansion gap but also provides a smooth transition between different height profiles and materials.

Can you use grout on laminate?

No, grout is not suitable for use with laminate flooring because laminate needs to expand and contract freely, and grout would prevent this, potentially causing damage.

What tools are best for cutting laminate?

The best tools for cutting laminate are:

- A miter saw or circular saw for straight cuts.

- A jigsaw for curved or intricate cuts.

- A fine-tooth blade or laminate-specific blade is crucial for all tools to ensure clean cuts.

Why does my laminate floor scratch so easily?

Laminate floors can scratch easily if they have a softer surface layer or if they are exposed to abrasive particles, heavy furniture without proper padding, or pets with sharp nails. Using high-quality laminate with a durable wear layer and proper floor protectors can help mitigate scratching.

Should I cut laminate upside down?

When using a circular saw, it’s advisable to cut laminate upside down to minimize chipping of the decorative surface. When using a handsaw or jigsaw, keep the decorative surface facing up.