A Dry Tile Cutter is a specialized tool used primarily for cutting tiles without the use of water. Unlike wet tile saws, which utilize water to cool the blade and reduce dust, dry tile cutters operate through a mechanical score-and-snap method. This approach makes them highly suitable for quick, clean cuts, especially when working indoors where water use may be inconvenient or messy.

Key Features of Dry Tile Cutters:

- Scoring Wheel: A sharp wheel that scores the tile to create a precise cut line.

- Breaking Mechanism: A lever or handle that applies pressure to snap the tile along the scored line.

- Adjustable Guide: Helps ensure straight and accurate cuts for various tile sizes.

Importance of Using the Right Tile Cutting Tool

Choosing the correct tile cutting tool is crucial for both the quality of the finished project and the efficiency of the work. Dry tile cutters, such as the Sigma 2B3 25 inch Tile Cutter or the VEVOR Manual Tile Cutter, offer significant advantages:

- Precision: Ensures crisp, clean cuts without damaging the tiles.

- Convenience: No setup for water or cleanup post-cutting, making it ideal for quick jobs.

- Portability: Lighter and easier to transport than wet saws, perfect for on-site adjustments.

For projects that require cutting special materials or intricate shapes, different tools might be necessary. For example, for intricate cuts in porcelain or stone, a wet tile saw like the DeWalt DWC860W Wet/Dry Tile Saw might be more appropriate due to its water-cooled blade which minimizes dust and chipping.

Comparative Table of Tile Cutters:

| Cutter Type | Best Use Case | Example Product |

|---|---|---|

| Dry Tile Cutter | Quick, straight cuts for ceramic tiles | Sigma 2B3 25 inch Tile Cutter |

| Wet Tile Saw | Complex cuts, hard materials | DeWalt DWC860W Wet/Dry Tile Saw |

| Manual Glass Cutter | Small, delicate glass tiles | Glass Cutter Tool |

Ensuring that you use the right tool for the right job not only affects the ease of your task but also impacts the quality of the finish, reducing waste due to mistakes or improper handling. For most standard tiling jobs involving ceramic or some less dense porcelain tiles, a quality dry tile cutter can provide quick, efficient, and clean results.

How Does a Dry Tile Cutter Work?

Manual Dry Tile Cutters

Dry Tile Cutters are essential tools for professionals and DIY enthusiasts who need precise, clean cuts without the mess associated with wet cutting methods. Manual dry tile cutters function through a simple yet effective mechanical process, which does not require electricity or water, making them ideal for quick jobs or locations without access to power.

Mechanism of Manual Dry Tile Cutters:

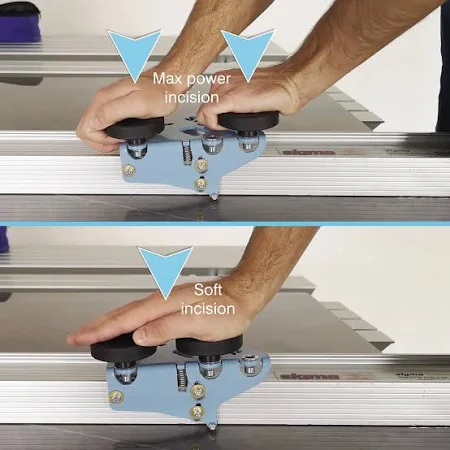

- Scoring the Tile: The cutter is equipped with a carbide or titanium-coated cutting wheel that scores the tile’s surface to define where the cut will be made. This wheel is manually drawn across the tile with a handle.

- Snapping the Tile: After scoring, the same handle is used to apply pressure along the score line. This pressure snaps the tile along the scored path, creating a clean break.

- Adjustments and Settings: Many models, like the Sigma 2B3 25 inch Tile Cutter and the Rubi TS-43 Max Tile Cutter, feature adjustable guides and measurement settings to accommodate tiles of different sizes and ensure straight cuts.

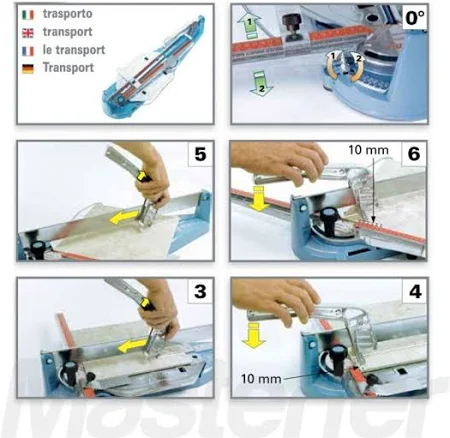

Step-by-Step Guide on Using a Manual Dry Tile Cutter:

- Measuring and Marking: Measure and mark your tile according to the required dimensions.

- Positioning the Tile: Place the tile in the cutter, aligning the score line with the cutting wheel.

- Scoring: Firmly press down on the handle and push or pull it across the tile to create a score line.

- Snapping: Apply a swift downward pressure on the handle at the edge of the tile to snap it along the scored line.

Advantages of Manual Dry Tile Cutters:

- No Power Required: Operates entirely manually, ideal for sites without electrical power.

- Less Dust and Debris: Since no water or high-speed cutting is involved, it produces less mess.

- Portability: Lightweight and easy to transport compared to wet saws.

Suitable Projects for Manual Dry Tile Cutters:

- Ideal for ceramic and porcelain tiles, particularly for installations like flooring, backsplashes, and wall tiling where water use is impractical.

Product Recommendations:

- The Sigma 2B3 25 inch Tile Cutter is renowned for its durability and precision, suitable for both amateur and professional use.

- For larger projects, the Rubi Hit N 48″ Professional Tile Cutter offers extended cutting length and enhanced leverage, making it perfect for cutting large-format tiles.

Mechanical vs. Dry Tile Cutters

Overview of Cutting Technologies

Dry Tile Cutters are a fundamental tool in the arsenal of both DIY enthusiasts and professional tilers. They differ significantly from mechanical cutters, which include an array of powered tools. Understanding the distinction between these two can help users choose the appropriate tool for their specific tiling project needs.

Mechanical Tile Cutters

Mechanical tile cutters are powered devices that generally use electricity to operate. They are ideal for heavy-duty tasks and can handle a variety of materials including porcelain, ceramics, glass, and even stone. The key types include wet tile saws and overhead motor wet saws.

Key Features:

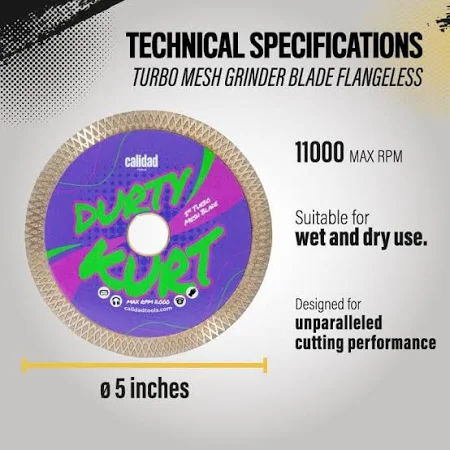

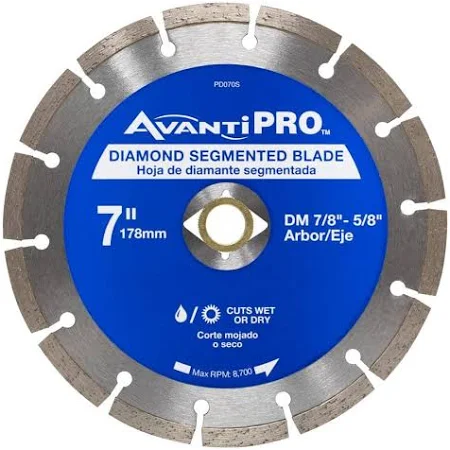

- Blade Type: Diamond-coated blades for cutting through hard materials.

- Water Cooling System: Uses water to cool the blade, reducing dust and prolonging blade life.

- High Precision: Offers clean and precise cuts, suitable for complex patterns and thick materials.

Popular Products:

- Rubi DC-250 Python Tile Saw: Known for its precision and ability to handle large tiles.

- DeWalt D24000S 10″ High Capacity Wet Tile Saw with Stand: Offers a robust design and high capacity for professional-grade projects.

Dry Tile Cutters

Dry tile cutters, on the other hand, are non-mechanical and operate manually without the need for electricity. They are simpler, lighter, and often more cost-effective than their mechanical counterparts.

Key Features:

- Scoring and Snapping Mechanism: Utilizes a simple score-and-snap operation.

- Portability: Lightweight and easy to transport, making them ideal for smaller projects or on-site cuts.

- No Dust Production: Since there is no cutting wheel or blade involved, no dust is produced during the cutting process.

Popular Products:

- Sigma 2B3 25 inch Tile Cutter: Offers excellent precision for ceramic and porcelain tiles.

- Rubi TS-43 Max Tile Cutter: Provides a sturdy design for frequent use and mobility.

Comparison Table: Mechanical vs. Dry Tile Cutters

| Feature | Mechanical Tile Cutters | Dry Tile Cutters |

|---|---|---|

| Operation | Electric-powered, often with a water cooling system | Manually operated with scoring and snapping |

| Best For | Thick, hard materials like porcelain and stone | Ceramic and softer porcelain tiles |

| Dust Production | Low to moderate (with water suppression) | None |

| Portability | Less portable due to size and weight | Highly portable |

| Initial Cost | Higher, due to complex mechanisms | Lower, simpler design |

| Maintenance | Requires regular maintenance of blade and motor | Minimal maintenance, occasional wheel change |

| Precision | High precision, suitable for complex cuts | Moderate precision, best for straight cuts |

Practical Applications

- Mechanical Tile Cutters: Best suited for large-scale commercial projects or renovations where precision and volume are necessary. Ideal for materials that require wet cutting to prevent cracking or chipping.

- Dry Tile Cutters: More suited for DIY projects, small repairs, or where convenience and speed are required. Perfect for straightforward jobs without access to power.

By understanding these distinctions, users can better decide which tile cutter to employ based on the material, project scale, and the environment in which they are working. Whether opting for a robust mechanical cutter like the DeWalt D24000S or a simple manual cutter like the Sigma 2B3 25 inch Tile Cutter, the choice should align with the specific needs of the project for optimal results.

Types of Dry Tile Cutters

Snap and Score Tile Cutters

Dry Tile Cutters are a staple in the toolkit of anyone who works with tile, whether professionally or as a DIY enthusiast. Among the various types, snap and score tile cutters are particularly popular due to their simplicity, effectiveness, and ease of use. These cutters are designed for precision and efficiency, allowing users to quickly score and snap tiles without the mess associated with wet cutting.

How Snap and Score Tile Cutters Work

Operation Process:

- Scoring the Tile: The cutter is equipped with a hardened wheel, which is run along the tile to create a shallow cut.

- Snapping the Tile: After scoring, the tile is snapped along the score line using a built-in mechanism. This is typically achieved by pressing down on a lever or handle that exerts force at the score line.

Key Features:

- Carbide or Titanium Cutting Wheel: Ensures a sharp and durable scoring edge.

- Adjustable Measuring Guide: Helps in making repetitive cuts and achieving precise measurements.

- Lightweight Design: Enhances portability and ease of handling, ideal for job sites.

Popular Snap and Score Tile Cutters

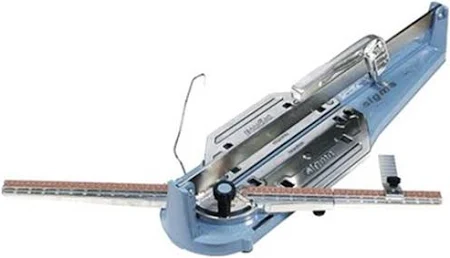

Sigma 2B3 25 inch Tile Cutter: Known for its precision and durability, ideal for both porcelain and ceramic tiles. It features a pull handle design that provides excellent leverage, making it easier to score and snap large tiles. Sigma 2B3 25 inch Tile Cutter.

Rubi TS-43 Max Tile Cutter: This model stands out for its robust construction and ability to handle different types of tiles. Its wide base and reinforced components ensure stability and precision during cutting. Rubi TS-43 Max Tile Cutter.

Comparing Snap and Score Tile Cutters

Advantages:

- No Power Required: These cutters do not require electricity, making them usable in any setting.

- Dust-Free Operation: Unlike wet saws or electric cutters, they do not produce dust or require water, offering a cleaner work environment.

- Cost-Effective: Generally cheaper than their mechanical counterparts and require less maintenance.

Limitations:

- Material Limitations: Best suited for ceramic and softer porcelain tiles. Harder materials like stone or thick porcelain may require a wet saw or a more robust mechanical cutter.

- Size Limitations: While capable of handling various tile sizes, extremely large or thick tiles might not be suitable for smaller snap and score models.

Ideal Usage Scenarios:

- Home Renovations: Perfect for DIY projects like bathroom renovations or kitchen backsplashes where precision and cleanliness are desired.

- Professional Settings: Excellent for professionals who require a quick, accurate, and portable solution for tiling jobs on various sites.

Manual Dry Tile Cutters

Overview of Manual Dry Tile Cutters

Dry Tile Cutters are essential tools for precise and clean cutting of tiles without the use of water. Manual dry tile cutters, which operate without electricity, offer simplicity and effectiveness for cutting ceramic, porcelain, and sometimes glass tiles. They are particularly valued for their portability and ease of use in various settings.

How Manual Dry Tile Cutters Work

Manual dry tile cutters utilize a straightforward mechanical process:

- Scoring: A carbide or titanium wheel scores the tile.

- Snapping: The tile is then snapped along the score line using a built-in mechanism.

This method is preferred for its cleanliness and efficiency, eliminating the mess associated with wet cutting.

Key Features

- Scoring Wheel: Hardened cutting wheels ensure a sharp, consistent score line.

- Built-in Measuring Guides: Help achieve accurate, repeatable cuts.

- Adjustable Pressure: Allows control over the snapping mechanism to accommodate different tile thicknesses.

Popular Models of Manual Dry Tile Cutters

Sigma 2B3 25 inch Tile Cutter: Renowned for its durability and ability to handle tiles of various sizes with precision. Perfect for both DIY projects and professional use. Sigma 2B3 25 inch Tile Cutter

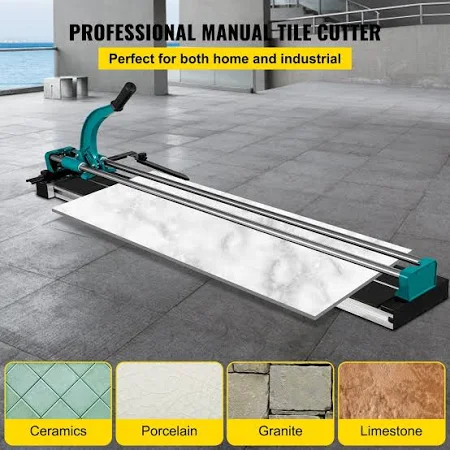

Rubi TS-43 Max Tile Cutter: Offers excellent capabilities in cutting large tiles thanks to its robust design and easy-to-use snapping system. Rubi TS-43 Max Tile Cutter

VEVOR Manual Tile Cutter: Known for its precise cutting ability and versatility with features like an infrared cutting guide for extra precision. VEVOR Manual Tile Cutter Cutting Machine with Infrared

Benefits of Using Manual Dry Tile Cutters

- Portability: No need for electrical power, can be used on any jobsite.

- Clean Operation: Does not produce dust or require water, making it suitable for indoor use.

- Cost-Effective: Less expensive than wet saws and requires minimal maintenance.

Limitations

- Material Restrictions: While effective for ceramic and porcelain, harder materials like stone may not be suitable.

- Thickness Limitations: Thicker tiles might require multiple scoring passes or might not be compatible at all.

Ideal Use Cases

- Home Renovations: Perfect for small to medium tiling jobs like kitchen backsplashes and bathroom floors.

- Professional Jobs: Suitable for quick, on-site adjustments where setup time and space are limited.

Rail Cutter vs. Table Cutter

Understanding Rail Cutters and Table Cutters

Dry Tile Cutters serve a crucial role in the precise and efficient cutting of tiles, whether for professional or DIY projects. Among the various types, rail cutters and table cutters are particularly noteworthy, each suited to different needs and preferences. Understanding the distinctions between these tools can significantly impact the quality and ease of tile cutting tasks.

Rail Cutters

Rail cutters are manual tile cutters that operate on a simple mechanism where the tile is scored and then snapped using a lever system. They are characterized by their linear rail system, which guides a scoring wheel across the tile.

Key Features:

- Portable Design: Typically lighter than table cutters, making them easy to transport and set up.

- Precision: Offers clean and straight cuts with adjustable scoring pressure.

- Ease of Use: Simple operation without the need for electricity or water.

Popular Models:

- Sigma 2B3 25 inch Tile Cutter: Renowned for its precision and ease of use, perfect for cutting both ceramic and porcelain tiles. Sigma 2B3 25 inch Tile Cutter

- VEVOR Manual Tile Cutter Single Rail: Known for its robust construction and reliable performance. VEVOR Manual Tile Cutter Single Rail

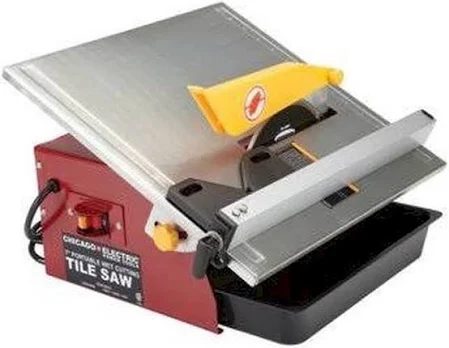

Table Cutters

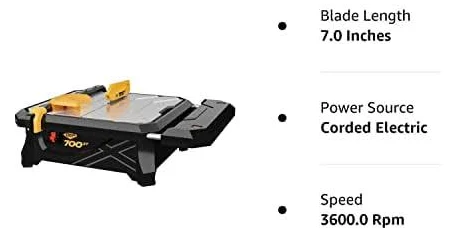

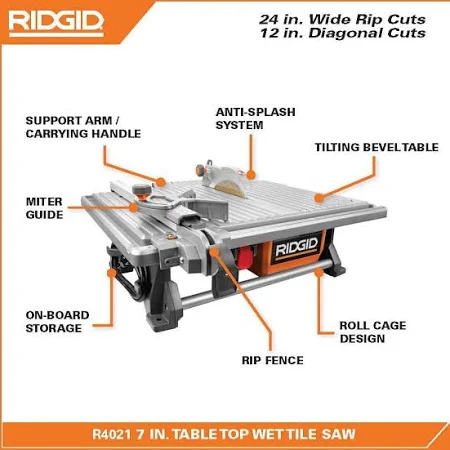

Table cutters, often referred to as tile saws, are more complex and generally electric-powered. They use a diamond-coated circular blade to cut through tiles, which is cooled with water to reduce dust and extend blade life.

Key Features:

- High Capacity: Suitable for heavy-duty cutting and larger projects.

- Versatility: Can cut various types of tiles and thicknesses, including stone and thicker tiles.

- Water Cooling System: Minimizes dust and cooling the blade, preventing overheating.

Popular Models:

- DeWalt D24000S Wet Tile Saw: Offers high capacity for large tiles and is noted for its durability and precision. DeWalt D24000S Wet Tile Saw

- Rubi DC-250 Python Tile Saw: Ideal for professional use with features that support precision cutting for complex projects. Rubi DC-250 Python Tile Saw

Comparison of Rail Cutters and Table Cutters

| Aspect | Rail Cutter | Table Cutter |

|---|---|---|

| Design | Lightweight, portable | Bulkier, stationary |

| Operation | Manual scoring and snapping | Electric-powered cutting with water bath |

| Best For | Straight cuts, smaller projects | Complex cuts, all tile types |

| Dust Production | Minimal | Low (with water suppression) |

| Maintenance | Low maintenance | Higher maintenance due to moving parts |

Choosing Between Rail and Table Cutters

- For DIY Projects: Rail cutters are usually sufficient for home renovations or smaller tiling jobs where simplicity and portability are valued.

- For Professional Use: Table cutters are more suitable for continuous, high-volume cutting or when working with a variety of materials that require different cutting techniques.

Compact vs. Heavy-Duty Tile Cutters

When selecting the right Dry Tile Cutter for a project, one critical decision is choosing between compact and heavy-duty models. Each type caters to different needs based on the scale of the job, the material to be cut, and the precision required.

Compact Tile Cutters

Compact tile cutters are designed for smaller projects and spaces where portability is key. They are ideal for quick jobs or where storage space is limited.

Features of Compact Tile Cutters:

- Portability: Lightweight and easy to transport, making them perfect for DIY projects and professional tasks that require moving around.

- Simplicity: Often manual, these cutters are straightforward to use with minimal setup time.

- Suitability: Best for smaller tiles or jobs that require less frequent cutting.

Popular Models Include:

- Sigma 7F Standard 14″ Pull Handle Tile Cutter: This model offers ease of use with a straightforward pull handle mechanism for smaller projects. Sigma 7F Standard Tile Cutter

- Vitrex Handheld Tile Cutter: A handheld option that is excellent for making quick, simple cuts on the go. Vitrex Handheld Tile Cutter

Heavy-Duty Tile Cutters

Heavy-duty tile cutters are built to handle larger, more challenging projects that require cutting thicker materials or bulk quantities.

Features of Heavy-Duty Tile Cutters:

- Power and Durability: These cutters often use electric motors to handle tough materials like porcelain and stone with ease.

- Larger Blade Capacity: Equipped to manage larger tiles, reducing the time and effort needed for big projects.

- Precision: Advanced features such as cutting guides and built-in measuring systems to ensure accurate cuts.

Popular Models Include:

- DeWalt D36000S 10″ High Capacity Wet Tile Saw: Known for its robust design and high-capacity cutting, suitable for extensive tiling projects. DeWalt D36000S High Capacity Wet Tile Saw

- Rubi DC-250 Python Tile Saw: A professional-grade cutter that offers precision and the ability to handle very large tiles. Rubi DC-250 Python Tile Saw

Comparison: Compact vs. Heavy-Duty

| Feature | Compact Tile Cutters | Heavy-Duty Tile Cutters |

|---|---|---|

| Intended Use | Small-scale projects, quick jobs | Large-scale projects, frequent usage |

| Portability | High (lightweight, smaller size) | Low (larger, heavier) |

| Tile Size | Smaller tile sizes | Larger tile sizes and thicker materials |

| Power Source | Manual, some electric models | Predominantly electric |

| Typical Users | DIY enthusiasts, small contractors | Professional tilers, large contractors |

Choosing the Right Cutter for Your Needs

The choice between a compact and a heavy-duty tile cutter depends on your specific project requirements:

- For occasional, light use or smaller tiles, a compact tile cutter is sufficient.

- For frequent use, larger or harder materials, a heavy-duty model is more appropriate to handle the increased workload and provide longer service life.

Advantages of Using a Dry Tile Cutter

The use of a Dry Tile Cutter provides several advantages that are beneficial for both casual and professional users in terms of efficiency, cost, and ease of use.

Clean and Accurate Cuts

Dry tile cutters are designed to deliver sharp and precise cuts, making them ideal for detailed tiling projects where accuracy is paramount. The cutting action usually involves a scoring wheel that creates a pressure line on the tile. This technique allows for a clean break along the scored line, reducing the risk of chipping or cracking the tile.

- Sigma 2B3 25 inch Tile Cutter: Known for its precise scoring capability, making it a top choice for achieving clean cuts. Sigma 2B3 25 inch Tile Cutter

No Water Needed

Unlike wet tile saws, dry tile cutters do not require water for operation. This feature simplifies the setup, reduces mess, and eliminates the need for a water source, which can be particularly advantageous in locations where water access is limited.

- Rubi Hit N 48″ Professional Tile Cutter: Provides efficient cutting without the mess of water, perfect for quick jobs on-site. Rubi Hit N 48″ Professional Tile Cutter

Cost-Effective Solution

Dry tile cutters are generally less expensive than their wet counterparts. They also require less maintenance and do not have components that may rust or wear out quickly due to water exposure, making them a cost-effective choice for tile cutting tasks.

- QEP 48 in. Manual Tile Cutter: Offers a budget-friendly option without compromising on the quality of cuts. QEP 48 in. Manual Tile Cutter

Portable and User-Friendly

The lightweight and compact design of most dry tile cutters enhance their portability, making them easy to transport from one job site to another. They are straightforward to operate, which makes them accessible even to those with minimal experience in tiling.

- Sigma Series 4 NEX Push Tile Cutter: Combines portability with ease of use, suitable for both professionals and DIY enthusiasts. Sigma Series 4 NEX Push Tile Cutter

Summary Table of Advantages

| Advantage | Key Feature | Example Product |

|---|---|---|

| Clean and Accurate Cuts | Precision scoring and cutting | Sigma 2B3 25 inch Tile Cutter |

| No Water Needed | Simplifies setup and reduces mess | Rubi Hit N 48″ Professional Tile Cutter |

| Cost-Effective | Lower purchase and maintenance costs | QEP 48 in. Manual Tile Cutter |

| Portable and User-Friendly | Lightweight and easy to operate | Sigma Series 4 NEX Push Tile Cutter |

Best Dry Tile Cutters in the Market

When it comes to tiling, having the right tool is crucial for achieving professional results. Below, we explore some of the best dry tile cutters currently available, each known for specific features that cater to different cutting needs.

Product 1: iQ228CYCLONE 7″ Dry Cut Tile Saw

Features:

- Blade Size: 7-inch diamond cutting blade.

- Cutting Ability: Cuts ceramic, porcelain, marble, and stone.

- Dust Control: Integrated vacuum and dust containment system.

Pros:

- Precision Cutting: Enables accurate and clean cuts with minimal chipping.

- Dust Reduction: High-efficiency dust vacuum system keeps the workspace clean.

- Portability: Lightweight and compact design for easy transportation and storage.

Cons:

- Price: Higher price point compared to some other models.

- Blade Wear: Replacement blades can be expensive.

Product 2: Alpha Ecocutter Dry Tile Cutting System ECC-125

Features:

- Blade Size: 4.5-inch and 5-inch blade options.

- Cutting Ability: Designed for granite, marble, porcelain, and engineered stone.

- Design: No water needed with a built-in dust collection system.

Pros:

- Versatility: Suitable for various materials including dense porcelain tiles.

- Dust Management: Effective dust collection system for cleaner operations.

- Compact Design: Easy to maneuver and ideal for tight spaces.

Cons:

- Limited Cutting Depth: Not suitable for very thick materials.

- Power Requirement: Electric power source needed, limiting mobility at remote sites.

Product 3: iQTS244 10″ Dry Cut Tile Saw

Features:

- Blade Size: 10-inch Q-Drive hard material blade.

- Cutting Ability: Capable of handling large format tiles and stone.

- Safety: Fully enclosed blade and integrated dust control system.

Pros:

- Large Capacity: Ideal for large tiles and slabs, reducing need for multiple cuts.

- Safety Features: Enclosed design prevents accidents and controls dust efficiently.

- Quiet Operation: Quieter than conventional tile saws.

Cons:

- Bulkiness: Heavier and less portable than smaller models.

- Investment: High upfront cost but justified by the professional-grade capabilities.

Product 4: Makita 4100KB 5″ Dry Masonry Saw

Features:

- Blade Size: 5-inch diamond blade.

- Cutting Ability: Cuts through stone, masonry, tile, and concrete.

- Dust Extraction: Equipped with a dust extraction port for clean operations.

Pros:

- Powerful Cutting: Robust motor ensures efficient cutting through tough materials.

- Ease of Use: Lightweight and ergonomic design for user comfort.

- Dust Control: Effective dust management system for safer and cleaner use.

Cons:

- Depth Adjustment: Limited adjustability on cutting depth.

- Noise Level: Slightly louder operation compared to other dry cut saws.

Comparison Table of Top Dry Tile Cutters

| Product Name | Blade Size | Cutting Material | Weight | Special Feature |

|---|---|---|---|---|

| iQ228CYCLONE 7″ Dry Cut Tile Saw | 7-inch | Ceramic, porcelain, stone | Light | Dust containment system |

| Alpha Ecocutter ECC-125 | 4.5-inch, 5-inch | Granite, marble, porcelain | Compact | Built-in dust collection |

| iQTS244 10″ Dry Cut Tile Saw | 10-inch | Large format tiles, stone | Heavy | Safety enclosure, quiet |

| Makita 4100KB 5″ Dry Masonry Saw | 5-inch | Stone, masonry, tile, concrete | Medium | Dust extraction port |

These cutters represent a range of capabilities and features to meet various cutting requirements, from DIY home projects to professional construction tasks.

How to Choose the Best Dry Tile Cutter

Selecting the best dry tile cutter requires careful consideration of several factors to ensure you have the right tool for your specific tiling project needs. Here, we’ll guide you through the key aspects to consider, helping you make an informed decision.

1. Tile Material and Thickness

- Material Specificity: Different tiles such as porcelain, ceramic, glass, or stone have varying hardness and density, which influences the type of cutter required. For instance, a best tile cutter for porcelain must have a durable blade capable of making clean cuts through hard materials without causing damage.

- Thickness Considerations: The thickness of the tile also plays a crucial role. Thicker and larger tiles will require a cutter with a deeper cut capacity and possibly a larger blade. For large format tiles, consider using a large format tile cutter.

2. Blade Quality and Durability

- Blade Material: High-quality diamond blades are essential for dry tile cutters to ensure precise and clean cuts. Products like the diamond blade for grinder offer durability and are suitable for various tile types.

- Replacement and Cost: Consider the availability and cost of replacement blades. A cutter that uses standard sized blades might be more cost-effective in the long run.

3. Cutter Size and Portability

- Workspace and Storage: Your workspace will determine the size of the tile cutter. For smaller, more confined spaces, a small tile cutter may be more appropriate.

- Portability Needs: If you need to move the cutter between various job sites, options like the hand held tile cutter are ideal for their ease of transport and setup.

4. Ease of Use and Maintenance

- User-Friendly Design: Look for features that enhance usability, such as adjustable guides, easy-to-read measurements, and comfortable handles.

- Maintenance Requirements: Some cutters, like the electric tile cutter, may require more maintenance due to their mechanical components. Consider how easy it is to clean and maintain the cutter to ensure longevity.

Comparison Table of Popular Dry Tile Cutters

| Product Name | Suitable Tile Type | Blade Size | Features | Link |

|---|---|---|---|---|

| Sigma 2D4 Professional Tile Cutter | Porcelain, Ceramic | 24 Inch | Manual, lightweight | Sigma 24 Inch |

| Muzata Large Format Cutter | Porcelain, Ceramic, Stone | 48 Inch | Manual, suitable for large tiles | 48 Inch Cutter |

| Ryobi Tile Cutter | All Tile Types | Various | Electric, versatile | Ryobi Cutter |

Step-by-Step Guide: How to Use a Dry Tile Cutter

Using a dry tile cutter effectively can streamline your DIY projects or professional jobs by providing clean, precise cuts without the mess of water-based systems. Here’s how to utilize one of these tools properly from start to finish.

Tools You’ll Need

- Dry Tile Cutter: Choose a high-quality dry tile cutter suited to the tile material. Options like the Sigma 48 Inch Tile Cutter are excellent for larger tiles.

- Measuring Tape and Marker: Essential for accurate measurements and markings on your tiles.

- Safety Equipment: Safety goggles, gloves, and dust masks are necessary to protect against tile shards and dust.

Preparing the Tile and Cutter

- Measure and Mark Your Tile: Use a measuring tape to determine where the tile needs to be cut. Mark the tile with a non-permanent marker at the desired measurement.

- Set Up the Cutter: Position the tile in the cutter, aligning your marked line with the cutting wheel. Ensure the tile is snug against the guide to avoid any slippage during the scoring process.

Scoring the Tile

- Score the Tile: Gently press the cutting wheel onto the surface of the tile and push or pull the cutter along the marked line in one smooth motion. This will create a score line, which is where the tile will break. Be sure to apply even pressure from start to finish to ensure a clean score.

Snapping the Tile for a Clean Cut

- Snap the Tile: After scoring, position the “snapping wings” or the mobile part of the cutter at the ends of the scored line. Apply firm pressure downwards until the tile snaps along the scored line. This should result in a clean, straight cut.

Safety Tips During Cutting

- Wear Protective Gear: Always wear safety goggles and gloves to protect against flying particles and sharp edges.

- Work in a Well-Ventilated Area: Especially important when cutting materials like porcelain or stone that can produce silica dust.

- Keep the Work Area Clean: Regularly clean up debris to prevent slips and ensure good visibility.

By following these steps, you can achieve professional-quality cuts using a dry tile cutter like the Ryobi Tile Cutter for smaller, more intricate work, or the robust Cortag Mega 125 Manual Tile Cutter for larger tiles. Whether you’re updating your kitchen, bathroom, or embarking on a new construction project, the right tools and techniques are crucial for successful tile installation.

Common Problems When Using Dry Tile Cutters and How to Fix Them

Dry tile cutters are essential tools for precise and clean tile cutting. However, users may occasionally encounter issues that can affect the quality of the cut. Here’s a detailed look at common problems and their solutions to ensure your dry tile cutting experience remains smooth.

Tiles Chipping or Breaking

Problem: Tiles may chip or break if the scoring is not deep enough or the cutter wheel is worn out.

Solutions:

- Ensure Proper Scoring: Double-check that you score the tile deeply enough before snapping. The score line should be clear and uniform.

- Replace Worn Cutting Wheels: Inspect the cutting wheel regularly and replace it if it shows signs of wear. For high-quality replacements, consider options like the Diamond Blade For Grinder, which provides precise cuts and long-lasting performance.

- Adjust Pressure: Apply consistent and adequate pressure when scoring and snapping. Too much force can break the tile, especially delicate materials like porcelain.

Blade Not Cutting Properly

Problem: The blade may not cut effectively if it becomes dull or is not suited for the tile material.

Solutions:

- Use the Right Blade: Make sure the blade is suitable for the type of tile you are cutting. For tougher materials like porcelain, use a specialized blade such as those found in Sigma Tile Cutters.

- Replace or Sharpen the Blade: Regularly replace or sharpen the blade to maintain optimal cutting performance. High-quality blades from Vevor Tile Cutters are designed for various tile materials and can help achieve cleaner cuts.

Misaligned Cuts

Problem: Cuts may not follow the intended line if the tile is not properly secured or the guide is misaligned.

Solutions:

- Check the Cutter Setup: Before cutting, ensure the tile is firmly secured and aligned correctly against the guide of the cutter.

- Calibrate the Cutter: Regularly check and adjust the alignment of the cutter’s guide to ensure it is square. This is particularly crucial for complex cuts or when using large-format cutters like those from Cortag Tile Cutters.

- Practice Makes Perfect: Make some test cuts on spare tiles to adjust your technique before proceeding with actual project tiles.

Dry Tile Cutter vs. Wet Tile Cutter: Which One Should You Use?

Choosing the right tile cutter is crucial for achieving the best results in any tiling project. Both dry and wet tile cutters have their unique advantages and ideal applications. Here, we will explore the differences between these two types of tile cutters, weigh their pros and cons, and determine which situations are best suited for dry tile cutters.

Differences Between Dry Tile Cutters and Wet Tile Cutters

Dry Tile Cutters:

- Operate without the use of water.

- Utilize a simple score-and-snap technique.

- Best for smaller or thinner tiles.

- Produce less mess and are more portable.

Wet Tile Cutters:

- Use water to cool the cutting blade and reduce dust.

- Employ a diamond blade to cut through tiles, which allows for cutting thicker and harder materials.

- Require electricity and a stable setup to operate efficiently.

- Tend to be more accurate for complex cuts.

Pros and Cons of Each Type

Dry Tile Cutters

Pros:

- Portability: They are lightweight and easy to transport, making them ideal for jobs on different sites.

- Less Mess: Since no water is used, the work area remains dry and clean.

- Quick Setup: Ready to use with minimal setup required.

Cons:

- Limited Capability: Not suitable for cutting very thick or hard materials like thick porcelain or stone tiles.

- Rougher Edges: May produce rougher edges which might require additional smoothing.

Wet Tile Cutters

Pros:

- Precision Cuts: Capable of making precise cuts, including L-cuts and U-cuts, on a variety of tile materials.

- Versatility: Can handle tougher materials like porcelain and stone due to the robust diamond blades used.

Cons:

- Setup Time: Requires setup and access to water and power.

- Cleanup: The use of water can lead to a messy work area, necessitating cleanup after use.

Ideal Applications for Dry Tile Cutters

Dry tile cutters are especially beneficial in scenarios where simplicity, speed, and convenience are paramount. They are particularly well-suited for:

- Small Projects: Ideal for DIY projects or small repairs where you need to cut a limited number of tiles.

- Dry Environments: Perfect for quick jobs in areas where water use is inconvenient or where electricity is not readily available.

- Simple Materials: Best used with ceramic tiles or any soft-bodied tiles where precision is not the primary concern.

For larger or more complex projects involving tougher materials, a wet saw tile cutter is often a better choice due to its precision and ability to handle harder materials. Additionally, for those working frequently with porcelain, exploring the best tile cutter for porcelain is advisable as these are specifically designed to handle the hardness of porcelain tiles.

Maintenance Tips for Dry Tile Cutters

Maintaining your dry tile cutter is essential to ensure it continues to perform at its best. Proper care extends the life of the cutter and ensures it delivers precise cuts when you need them. Here’s how to keep your dry tile cutter in top condition:

Cleaning the Blade and Cutter

- After Each Use: Clean the blade and the body of the cutter. Use a brush to remove debris and dust from the blade and the cutting area. This prevents build-up which can affect the cutter’s performance.

- Deep Cleaning: Occasionally, it’s beneficial to give your tile cutter a more thorough clean. For this, dismantle the blade from the cutter if possible and clean it using soapy water. Dry thoroughly before reassembling to avoid rusting.

Lubricating Moving Parts

- Regular Lubrication: Apply a light machine oil to the scoring wheel and any other moving parts. This reduces friction, making the cutter easier to operate and prolonging the life of moving components.

- Check Monthly: Make it a routine to check and lubricate the moving parts at least once a month or according to the frequency of use.

Replacing the Cutting Wheel

- Identify Wear: Over time, the cutting wheel will wear down and need replacing. Signs of wear include uneven scoring lines or a wheel that no longer rotates smoothly.

- Replacement Process: Refer to your cutter’s manual for specific instructions on how to replace the wheel. Typically, this involves loosening a screw or bolt, replacing the wheel, and then securing it back in place.

Product-Specific Tips:

- For cutters like the Sigma Tile Cutter 48 Inch, ensure that the cutting wheel is specific to the model to maintain optimal performance.

- When using robust models like the Mk Tile Saw, regular maintenance of the diamond blade is crucial due to its intensive usage pattern.

Safety Tips During Maintenance

- Unplug Electric Models: If your tile cutter is electric, such as the Electric Tile Cutter, make sure it is unplugged before performing any maintenance.

- Wear Protective Gear: Always wear gloves to protect your hands from sharp edges during the cleaning and blade changing processes.

- Follow Manufacturer’s Guidelines: Always adhere to the manufacturer’s maintenance guidelines to ensure you are performing all tasks correctly and safely.

Are Dry Tile Cutters Good?

Dry tile cutters are highly effective tools for specific tiling tasks, offering significant advantages over wet tile cutters in certain scenarios. They provide clean, precise cuts without the mess created by the water used in wet cutting. Dry cutters like the Sigma Tile Cutter 48 Inch are particularly good for jobs where portability is crucial, as they don’t require a water source or setup time associated with wet cutters.

Advantages of Dry Tile Cutters:

- No Water Needed: Makes them more convenient and less messy.

- Portability: Easier to transport and use on-site where water access may be limited.

- Fast Setup and Operation: Ideal for jobs requiring quick, repetitive cutting.

Limitations:

- Dust Production: Cutting dry can produce a significant amount of dust, which requires good ventilation or a dust extraction system.

- Material Limitations: Not suitable for very thick or dense tiles, such as some porcelain tiles.

Difference Between Wet and Dry Tile Cutters

- Wet Tile Cutters: Use water to cool the cutting blade and reduce dust during the cutting process. This type is preferred for heavy-duty or continuous cutting, particularly with dense materials like porcelain or stone. Water also enhances the cut quality and extends the blade’s life.

- Dry Tile Cutters: Operate without water, usually employing a diamond-coated blade that cuts through friction and pressure. They are favored for their convenience and ability to make quick cuts without setup delays.

Can You Cut Tile Without Water?

Yes, tiles can be cut without water using a dry tile cutter. Devices like the Sigma Series 4 NEX Push Tile Cutter are designed to operate dry and are perfect for jobs requiring mobility and speed. However, cutting dry usually produces more dust, so proper safety measures should be taken.

How Do You Cut Dry Tile?

Cutting dry tile involves several key steps to ensure precision and prevent damage to the tile:

- Mark the Tile: Use a pencil or chalk to mark where you want to cut.

- Align the Tile: Position the tile in the cutter, aligning the cutting wheel with the marked line.

- Score the Tile: Apply firm, even pressure as you pull or push the cutting wheel across the surface of the tile to score it.

- Snap the Tile: Once scored, use the breaker built into the cutter to snap the tile along the scored line cleanly.

Why Do You Use Water When Cutting Tile?

Water serves multiple purposes in tile cutting:

- Cooling the Blade: It prevents overheating of the diamond blade, which can warp or wear down quickly from heat generated by friction.

- Reducing Dust: It helps in binding the dust produced during cutting, keeping the work environment cleaner and safer.

- Enhancing Cut Quality: Water reduces friction and facilitates a smoother cut, reducing the chances of chipping or breaking the tile.

How Thick of a Tile Can a Tile Cutter Cut?

The maximum thickness a tile cutter can handle depends on the model and design. For manual tile cutters, like those in the Sigma range, the standard capacity is typically around 0.5 to 0.75 inches (about 12 to 19 mm). However, heavy-duty cutters like the Sigma 2D4 Professional Tile Cutter can handle thicker tiles, often up to about 1 inch (25 mm). For cutting tiles thicker than this, more specialized equipment or a powerful electric tile cutter might be necessary.