A Tile Cutter Machine is a specialized tool designed to cut various types of tiles, including ceramic, porcelain, and stone. These machines are essential for achieving precise cuts and come in various forms such as manual, electric, and handheld devices. They are equipped with sharp blades or wheels that score and snap the tiles cleanly.

Types of Tile Cutter Machines:

- Manual Tile Cutters: Ideal for small projects and straightforward cuts.

- Electric Tile Cutters: These utilize a powered diamond blade and are suitable for complex and high-volume cutting tasks.

- Handheld Tile Saws: Provide flexibility for cutting irregular shapes or making onsite adjustments.

Why is it Essential for Tile Projects?

Tile Cutter Machines are indispensable in both DIY and professional tiling projects for several reasons:

Precision and Accuracy:

- Ensure exact cuts: Necessary for fitting tiles in complex layouts or tight spaces.

- Minimize material waste: Accurate cuts reduce the amount of tile wasted, making the project more cost-effective.

Efficiency:

- Speed up the installation process: Machines like the QEP 700XT Wet Tile Saw allow for rapid cutting of multiple tiles without compromising quality.

- Allow for repeated cuts: Machines like the Sigma 2D4 Professional Tile Cutter are perfect for jobs requiring consistent tile sizes.

Versatility:

- Cut various tile materials: Machines are designed to handle everything from soft ceramic tiles to harder materials like porcelain and stone.

- Different cut types: From straight lines to bevels and jigsaw cuts, tile cutter machines equipped with the right blades can do it all.

Safety:

- Reduce risk of injury: Using a tile cutter machine helps avoid the hazards of manually scoring and snapping tiles, which can lead to sharp edges and debris.

Featured Product:

- RIDGID Tile Saw with Stand: A robust electric cutter ideal for large-scale projects or thick materials, offering precision and stability.

Types of Tile Cutters: A Complete Guide

Manual Tile Cutters

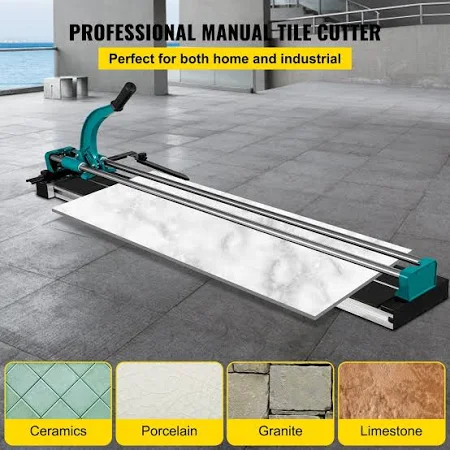

Manual tile cutters are the go-to choice for many DIY enthusiasts and professionals alike due to their simplicity, affordability, and precision. These tools are ideal for projects that require straight cuts on ceramic or porcelain tiles.

Advantages of Manual Tile Cutters:

- Ease of Use: They require minimal setup and are straightforward to operate.

- Portability: Without the need for electricity, they can be used at any location.

- Less Noise and Dust: Unlike power tools, manual tile cutters produce no dust and very little noise.

Types of Manual Tile Cutters:

Single Rail Cutters:

- Best for smaller projects with thinner tiles.

- Example: The Sigma Series 4 Up Pull Tile Cutter is perfect for precision on smaller ceramic tiles.

Dual Rail Cutters:

- Provide more stability and are suitable for larger, thicker tiles.

- Example: The 87 Inch Manual Tile Cutter, with its double rails design, offers precise cuts for large porcelain tiles.

Adjustable Handheld Tile Scorer:

- Ideal for making quick cuts and adjustments directly on the job site.

- Example: The ToolPro Shadowline Cutter offers adaptability for intricate cuts.

Selecting the Right Manual Tile Cutter:

- Tile Material: Choose a cutter based on the type of tile—ceramic, porcelain, or glass.

- Tile Size and Thickness: Ensure the cutter can handle the dimensions and thickness of your tiles.

- Frequency of Use: For regular use, invest in a high-quality model that ensures durability and precision.

Featured Manual Tile Cutters:

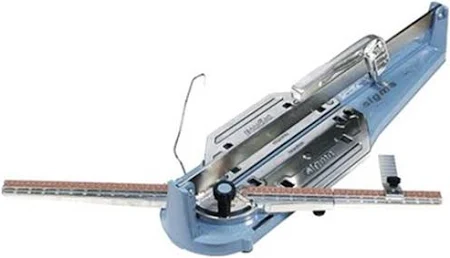

- Sigma 2D4 Professional Tile Cutter: Known for its durability and ability to cut up to 20-inch tiles with precision.

- MUFASHA 70 Inch Large Manual Tile Cutter: Ideal for large format tiles, providing clean and efficient cuts.

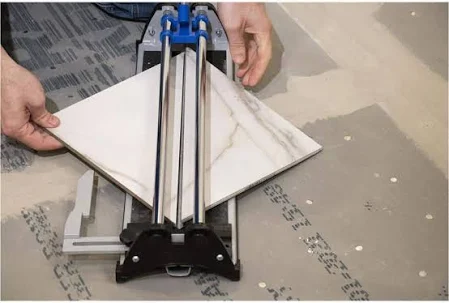

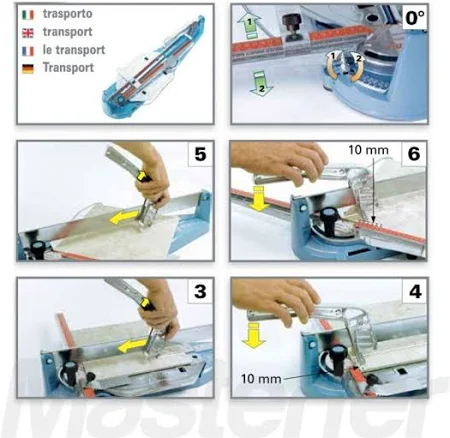

How to Use a Manual Tile Cutter:

- Measure and Mark Your Tile: Determine where the cut needs to be and mark it clearly on the tile.

- Position the Tile: Place the tile securely against the guide of the cutter.

- Scoring the Tile: Press down on the handle to engage the cutting wheel, and pull it across the tile to score it.

- Snapping the Tile: After scoring, press the handle or snapping foot to split the tile along the scored line.

Tile Cutter Machines (Electric and Portable)

Electric and portable tile cutters represent a significant leap in efficiency and precision for both small-scale and large-scale tiling projects. These machines come equipped with powerful motors and diamond-tipped blades, making them capable of handling a variety of materials including ceramics, porcelain, and even natural stone.

Advantages of Electric Tile Cutters:

- Precision Cutting: High-powered blades ensure clean and precise cuts with minimal chipping.

- Versatility: Suitable for a range of tile types, from delicate glass tiles to robust porcelain tiles.

- Speed: Greatly reduces the time required to cut large quantities of tile, which is crucial for bigger projects.

Types of Electric Tile Cutters:

Wet Tile Saws:

- Use a water-cooled diamond blade to make cuts that are both clean and cool, preventing overheating.

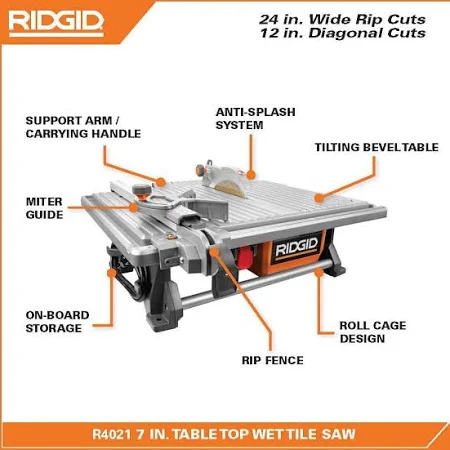

- Example: The RIDGID Tile Saw with Stand is a robust choice for professionals needing precision on extensive tile installations.

Overhead Motor Wet Saws:

- Feature a motor positioned above the blade for clear visibility and precise control over cuts.

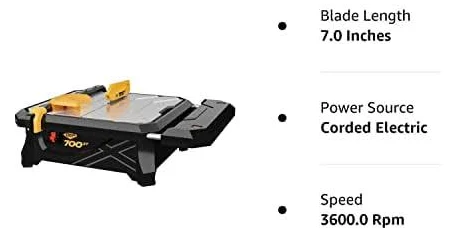

- Example: The QEP 700XT Wet Tile Saw combines power with portability, ideal for both DIY enthusiasts and professional tilers.

Handheld Tile Saws:

- Offer maximum flexibility for making freehand cuts and are perfect for cutting tile already installed.

- Example: The Ryobi Tile Cutter provides convenient portability and sufficient power for on-the-spot adjustments.

Selecting the Right Electric Tile Cutter:

- Power Source: Consider if you prefer a corded electric model for continuous power or a battery-operated model for unrestricted mobility.

- Blade Capacity: Ensure the blade can handle the tile size and type you intend to cut, with special considerations for depth adjustments.

- Water Feed System: Wet tile saws should have a reliable water feed to keep the blade cool and reduce dust.

Featured Electric Tile Cutters:

- Sigma Kera-Cut EXT 8AE2: Specializes in cutting large format tiles with its extendable design, making it ideal for handling up to 332 cm in length.

- Kobalt Ceramic Tile Cutter Kit: A comprehensive kit that offers versatility and ease of use for ceramic tiles, with attachments for various cutting styles.

How to Use an Electric Tile Cutter:

- Setup the Machine: Assemble the cutter according to the manufacturer’s instructions, ensuring the water reservoir is filled if using a wet saw.

- Measure and Mark Your Tile: Accurately measure and mark where the cut will be made on the tile using a non-permanent marker.

- Align the Tile: Place the tile on the cutting platform and align it with the cutting guide.

- Begin Cutting: Turn on the machine and gently push the tile into the blade, guiding it steadily to ensure a straight cut.

- Finishing the Cut: Allow the blade to completely stop before removing the cut pieces to prevent any damage or displacement.

By incorporating an electric or portable tile cutter into your toolkit, you can enhance the efficiency and quality of your tiling projects, from kitchen backsplashes to full room floor installations. These tools not only save time but also allow for greater creative freedom in design and material choices.

Handheld Tile Cutters

Handheld tile cutters are essential tools for anyone needing to make quick, precise cuts without setting up a larger, stationary machine. These cutters are particularly useful for making adjustments on already installed tiles or for projects where space is limited. They offer the flexibility to cut tiles at various angles and locations with minimal setup.

Advantages of Handheld Tile Cutters:

- Mobility: Easy to carry and use anywhere, ideal for repairs or installations in tight spaces.

- Ease of Use: Simple design allows for quick operation without extensive training.

- Cost-Effective: Generally less expensive than larger tile cutters and wet saws.

Types of Handheld Tile Cutters:

Manual Snap Cutters:

- Operate on a score and snap mechanism, suitable for straightforward, straight cuts.

- Example: Sigma 2B3 25 inch Tile Cutter provides a portable option for quickly snapping tiles on the go.

Handheld Wet Saws:

- Use a small water-fed saw to cut tiles, ideal for intricate cuts that require a wet blade.

- Example: DeWalt DWC860W Wet/Dry Tile Saw offers precision with the flexibility of wet and dry cutting options.

Rotary Bearing Cutters:

- Feature a rotating cutting wheel, perfect for circular cuts or complex shapes.

- Example: Vitrex Handheld Tile Cutter is great for scoring intricate designs and patterns on ceramic tiles.

Selecting the Right Handheld Tile Cutter:

- Tile Type: Consider the material of the tile (ceramic, porcelain, glass) as different cutters are optimized for different materials.

- Cutting Requirements: Assess the complexity of the cuts needed—straight, curved, or notched cuts may require specific types of handheld cutters.

- Ergonomics: Choose a cutter that feels comfortable in your hand, especially for projects requiring many cuts or extended use.

Featured Handheld Tile Cutters:

- Chicago Electric Power Tools Handheld Dry-Cut Tile Saw: Ideal for quick, dry cuts when electricity is accessible and minimal water mess is desired.

- Sigma TC2B3 26″ Pull Tile Cutter: Provides a unique pull mechanism that offers clean, sharp cuts with ease and portability.

How to Use a Handheld Tile Cutter:

- Mark the Tile: Use a pencil or marker to clearly indicate where the tile needs to be cut.

- Score the Tile: Place the cutter wheel at the start of the mark and press down firmly, pulling the cutter along the line to score the tile.

- Snap the Tile: For manual snap cutters, place the tile over a wire hanger or the edge of a surface and apply pressure on both sides of the score line to break the tile cleanly.

- Clean Up: Smooth the edges of the cut tile with sandpaper or a rubbing stone to remove any sharp edges.

Handheld tile cutters are invaluable for their portability and ease of use, making them a staple in both the professional tiler’s and the DIY enthusiast’s toolkit. Whether adjusting tiles during installation or adding finishing touches to a tiling project, a reliable handheld tile cutter can make the job easier and more efficient.

Tile Snap Cutters

Tile snap cutters, also known as score-and-snap cutters, are a fundamental tool for both DIY enthusiasts and professional tilers. They offer a simple yet effective way to make clean, straight cuts across ceramic and porcelain tiles. This type of cutter is particularly valued for its ease of use and ability to quickly handle repetitive cuts without the setup time and maintenance required by electric cutters.

Advantages of Tile Snap Cutters:

- Efficiency: Allows for rapid, repetitive cutting with minimal effort.

- Portability: Light and easy to transport, making them ideal for jobs on different sites.

- No Power Required: Operates without electricity, making it suitable for jobs where power access is limited.

Types of Tile Snap Cutters:

Single-Bar Snap Cutters:

- Best for small to medium projects.

- Example: The Sigma 2B3 25 inch Tile Cutter offers a compact design with effective cutting capabilities for smaller tiles.

Dual-Bar Snap Cutters:

- Provide greater stability and are suitable for larger tiles.

- Example: The VEVOR Tile Cutter 48 inch/1200mm Manual Tile Cutter Double Rail is designed for precision cutting of large format tiles with its robust double-rail system.

Adjustable Snap Cutters:

- Feature adjustable scoring wheels to accommodate different tile thicknesses and materials.

- Example: Rubi Hit N 48″ Professional Tile Cutter provides versatility with its adjustable scoring system, making it suitable for a variety of tile types.

Selecting the Right Tile Snap Cutter:

- Tile Material and Size: Choose a cutter based on the type of tiles you are working with. Larger and thicker tiles will require a more robust model.

- Precision Requirements: Consider cutters with built-in measuring guides or adjustable scoring wheels for projects requiring high precision.

- Durability: Opt for cutters with solid construction and good warranty terms to ensure longevity, especially for professional use.

Featured Tile Snap Cutters:

- Sigma Kera-Cut Extendable 8AE2: An extendable cutter perfect for large tiles, offering clean cuts with its unique scoring and snapping system.

- QEP 48 in. Manual Tile Cutter: Known for its durability and efficiency, this model is a favorite among professionals for its ability to handle various tile types.

How to Use a Tile Snap Cutter:

- Measure and Mark the Tile: Determine where you need to cut and use a straight edge to mark a clear line on the tile.

- Score the Tile: Place the tile in the cutter, aligning the scoring wheel with your mark. Push or pull the handle to score a single, uninterrupted line across the tile’s surface.

- Snap the Tile: Lift the handle and then press down quickly and firmly to snap the tile along the scored line.

- Finishing Touches: Smooth any rough edges using a tile file or sandpaper to prepare the tile for installation.

Tile snap cutters are indispensable for projects that require speed and precision without the fuss of setup and cleanup associated with wet saws. Whether you’re working on a small bathroom renovation or laying a new kitchen floor, a reliable snap cutter is a tool you’ll want to have on hand.

Ceramic Tile Cutters

Ceramic tile cutters are essential tools for anyone working with ceramic tiles, offering precision and ease of use that are critical for achieving professional-looking results. These cutters come in various forms, from simple manual models to sophisticated electric machines, tailored to different project needs and user preferences.

Types of Ceramic Tile Cutters:

- Manual Ceramic Tile Cutters: Often preferred for their portability and simplicity. Ideal for straight cuts on ceramic tiles.

- Electric Ceramic Tile Saws: Best for large projects or complex cuts that require high precision.

Key Features of Ceramic Tile Cutters:

- Scoring Wheel: Essential for manual cutters, the quality of the scoring wheel affects the cleanliness of the score line.

- Cutting Bed: Adjustable beds can accommodate tiles of various sizes, enhancing the cutter’s versatility.

- Water System: For electric cutters, a water feed reduces dust and cools the blade, which is crucial for cutting ceramic tiles smoothly.

Advantages of Using Ceramic Tile Cutters:

- Precision: Ensures clean, straight cuts with minimal chipping, essential for visible areas like edges and corners.

- Efficiency: Speeds up the cutting process, especially with features like built-in measurements and laser guides.

- Versatility: Many cutters can handle different types of ceramic tiles, including glazed, unglazed, and porcelain tiles.

Recommended Products:

- Sigma 2D4 Professional Tile Cutter: Ideal for professionals looking for a robust manual solution. Known for its precision and durability.

- QEP 700XT Wet Tile Saw: An electric cutter that offers a large cutting table and efficient water cooling system, perfect for intensive cutting tasks.

Choosing the Right Ceramic Tile Cutter:

- Tile Thickness and Size: Ensure the cutter can handle the thickness and dimensions of the tiles used in your project.

- Project Scale: Larger projects might benefit from electric cutters with stands and extended cutting surfaces.

- Portability Needs: Manual cutters are sufficient for small projects or on-site adjustments.

How to Use a Ceramic Tile Cutter:

- Setup: For manual cutters, ensure the guide is secure and the scoring wheel is sharp. For electric cutters, fill the water reservoir and ensure the blade is clean and sharp.

- Measure and Mark: Always measure twice and mark your tile with a non-permanent marker to ensure accuracy.

- Scoring (Manual): Place the tile in the cutter, aligning the wheel with the mark. Press down firmly and push the handle across the tile to score.

- Cutting (Electric): Align the tile on the cutting bed, turn on the saw, and gently push the tile through the blade.

- Snapping: After scoring, use the built-in snapper (if available) or apply gentle pressure on either side of the score line to break the tile cleanly.

- Finishing: Smooth any rough edges with a tile stone or sandpaper to prepare the tile for installation.

Ceramic tile cutters are invaluable for ensuring high-quality finishes in tile installation projects, whether you’re updating a kitchen backsplash or laying a new bathroom floor. Choosing the right cutter and mastering its use can greatly enhance the efficiency and outcome of your tiling work.

Floor Tile Cutters

Floor tile cutters are specialized tools designed to handle the rigors of cutting tiles for floor installation. These tools are essential for achieving precise cuts and fit, especially when working with durable materials like ceramic, porcelain, and stone used in flooring.

Types of Floor Tile Cutters:

- Manual Floor Tile Cutters: Best for small to medium-sized projects where precision and simplicity are key. Ideal for straight cuts.

- Electric Floor Tile Saws: Necessary for larger projects or when working with tougher materials that require more power to cut through.

Advantages of Floor Tile Cutters:

- Precision: Designed to offer clean and precise cuts, reducing tile waste and ensuring tight seams.

- Speed: Significantly speeds up the process of laying floor tiles, especially when multiple cuts are needed.

- Versatility: Some models are equipped to handle different types of floor tiles, from ceramic to more robust porcelain tiles.

Selecting the Right Floor Tile Cutter:

- Material Compatibility: Choose a cutter based on the type of tiles you are using. Porcelain tiles might require a more robust model with a diamond blade.

- Size Capacity: Consider the size of the tiles you will be working with. Larger cutters can handle tiles up to 24 inches or more.

- Additional Features: Look for features that enhance usability, such as adjustable measuring guides, extension tables, and built-in wheels for better mobility on the job site.

Featured Products:

- VEVOR Wet Tile Saw 7-inch 65Mn Steel Blade 3500 RPM Induction Motor: An electric cutter that provides the power and precision needed for cutting large and hard tiles quickly.

- Sigma 2D4 Professional Tile Cutter: A manual option known for its durability and ability to deliver clean, consistent cuts, perfect for ceramic floor tiles.

How to Use a Floor Tile Cutter:

- Setup: For manual cutters, ensure the device is on a stable surface. For electric saws, set up the water pump and ensure the blade is secure.

- Measure and Mark: Accurately measure and mark where you need to cut the tile, using a pencil or felt-tip marker.

- Scoring and Snapping (Manual):

- Place the tile in the cutter, align the blade with the mark.

- Push down on the lever to score the tile, then press to snap it along the scored line.

- Cutting (Electric):

- Secure the tile on the cutter bed, align it with the blade.

- Gently push the tile into the blade, using even pressure to ensure a clean cut.

- Make sure to use the water system to keep the dust down and the blade cool.

- Finishing: Check the edges of the cut tile. Use a rubbing stone or sandpaper to smooth any rough edges.

Floor tile cutters are indispensable for any serious tile installation project, providing the necessary precision and efficiency required for professional results. Whether you opt for a manual cutter for smaller jobs or an electric model for extensive flooring projects, the right tool can significantly enhance the quality and speed of your work.

Large Tile Cutters vs. Small Tile Cutters

When it comes to choosing between large and small tile cutters, the decision primarily depends on the specifics of the tiling project, including the size and type of tiles being cut and the precision required. Here we delve into the distinctions and capabilities of each type, helping you make an informed choice based on your tiling needs.

Large Tile Cutters

Large tile cutters are designed to handle bigger and thicker tiles, which are commonly used in commercial spaces and expansive areas in residential properties.

Advantages:

- Capacity to Handle Large Tiles: Can cut tiles over 24 inches in length and often up to 48 inches or more.

- Higher Cutting Power: Generally equipped with more robust cutting mechanisms and motors, suitable for dense materials like porcelain and stone.

- Enhanced Features: Often include features such as adjustable cutting guides, built-in laser guides, and stands to support larger tiles.

Recommended Products:

- Rubi Hit N 48″ Professional Tile Cutter: Ideal for precision cutting of large format tiles.

- Sigma Kera-Cut Extendable 8AE2: Extends to accommodate tiles up to several meters in length, perfect for large-scale projects.

Small Tile Cutters

Small tile cutters are more suited for residential projects or where tiles are generally smaller and less thick. These cutters are highly portable and easier to maneuver.

Advantages:

- Portability: Lightweight and easy to transport, ideal for jobs requiring on-site cutting.

- Ease of Use: Simpler mechanisms make them user-friendly, especially for DIY enthusiasts.

- Cost-Effective: Less expensive than large tile cutters, making them a good option for budget-conscious users.

Recommended Products:

- Sigma 2B3 25 inch Tile Cutter: A compact design perfect for small to medium-sized tiles used in residential settings.

- VEVOR Manual Tile Cutter Single Rail: Offers precision for smaller ceramic and porcelain tiles.

Choosing Between Large and Small Tile Cutters

When deciding which type of tile cutter to use, consider the following aspects:

- Size of the Tiles: Larger tiles will require a cutter with a larger capacity for both cutting length and tile thickness.

- Type of Project: Large commercial projects or extensive residential installations might benefit from the features of a large tile cutter.

- Frequency of Use: If the cutter is to be used often and on various types of tiles, investing in a more versatile, larger cutter might be more cost-effective in the long run.

- Storage and Transport: Small tile cutters are easier to store and transport, making them ideal for smaller workspaces and frequent travel.

Both large and small tile cutters have their unique benefits that cater to different tiling needs. For professional contractors working with large format tiles, investing in a robust large tile cutter is essential. However, for home renovations or smaller projects, a small tile cutter offers the convenience and affordability necessary for such tasks. Choosing the right tile cutter ensures efficiency, effectiveness, and satisfaction in your tiling projects.

Specialty Tile Tools (e.g., Tile Scribe, Tile Splitters)

When it comes to specialized tiling tasks, having the right tools can make all the difference. Tile scribes and tile splitters are two such tools, each designed for specific functions that facilitate precise tile cutting and fitting. Here’s a detailed look at these specialty tools, including when and how to use them effectively.

Tile Scribes

A tile scribe is a simple yet crucial tool used for scoring ceramic tiles to ensure a clean, controlled break. It’s especially useful for making precise cuts where a tile cutter might be too cumbersome.

Advantages of Tile Scribes:

- Precision: Allows for detailed scoring, perfect for custom cuts around obstacles or in tight spaces.

- Portability: Compact and easy to carry, making it ideal for on-site adjustments.

- Ease of Use: Simple to operate with minimal setup required.

Recommended Product:

- Faithfull Hand DIY Tile Cutter TCT Tipped: Offers a durable tungsten carbide tip designed for scoring ceramic tiles.

Tile Splitters

Tile splitters are designed to break tiles cleanly along a scored line. They are essential for projects requiring numerous similar cuts, providing a fast and efficient method to process tiles.

Advantages of Tile Splitters:

- Efficiency: Quickly splits tiles along scored lines, speeding up the installation process.

- Simplicity: Requires less technical skill than tile saws, making them accessible to DIYers.

- Cost-Effective: Generally less expensive than wet saws and electric tile cutters.

Recommended Product:

- Sigma 2B3 25 inch Tile Cutter: Combines a scribing tool with a powerful snapping function, suitable for both scoring and splitting tiles.

Choosing Between Tile Scribes and Tile Splitters

The choice between a tile scribe and a tile splitter often depends on the specific requirements of the tiling project:

- Tile Material: Scribes work best on ceramic tiles, while splitters can handle both ceramic and more brittle materials like glass, given an appropriate scoring line.

- Cutting Volume: For large projects, a splitter will save time. For intricate, detail-oriented jobs, a scribe provides the necessary precision.

- Skill Level: Splitters are user-friendly and require less skill than operating a wet saw, making them ideal for beginners or casual DIYers.

Using Tile Scribes and Splitters

Here’s how to effectively use these tools:

Using a Tile Scribe:

- Mark the Tile: Use a ruler and a non-permanent marker to draw your cut line.

- Score the Line: Place the scribe at one end of the mark and apply firm pressure as you drag it along the line. Repeat if necessary to deepen the score.

- Snap the Tile: Place the tile over a wire or the edge of a work surface and apply pressure on both sides of the scored line to break the tile.

Using a Tile Splitter:

- Score the Tile: First use a tile scribe or the scoring tool on the splitter to score the tile.

- Position the Tile: Place the tile in the splitter, aligning the scored line with the cutting edge.

- Split the Tile: Pull the handle (or press down, depending on the model) to split the tile along the scored line.

Tile scribes and tile splitters are indispensable tools for any tiling project, offering different functionalities tailored to various cutting needs. Whether you’re a professional tiler or a home DIY enthusiast, understanding when and how to use these tools can significantly enhance the precision and efficiency of your tile installation work.

Top Features to Look for in a Tile Cutter

Choosing the right tile cutter is essential for achieving professional results in tiling projects. Whether you are a DIY enthusiast or a professional, understanding the key features that differentiate various tile cutters can help you select the best tool for your needs. Here’s a guide on what to look for in a tile cutter.

Precision and Accuracy

- Cutting Guide and Laser Alignment: Features like adjustable guides and built-in laser pointers enhance cutting accuracy, ensuring straight and consistent cuts.

- Interchangeable Scoring Wheels: The ability to change scoring wheels based on tile material helps maintain precision across different tile types.

Durability of the Tool

- Robust Construction: Look for tile cutters with a strong metal base and durable components that can withstand frequent use and the rigors of cutting tough materials.

- Rust-resistant Materials: Stainless steel or aluminum components are preferable for longevity, especially in tools like the Sigma 2D4 Professional Tile Cutter.

Ease of Use (Manual vs. Machine)

- Manual Tile Cutters: Ideal for smaller or more precise jobs. They require less setup and are generally easier to transport. Models like the Sigma TC2B3 26″ Pull Tile Cutter offer simplicity with effective results.

- Electric Tile Saws: Best for large-scale projects or frequent cutting of very hard materials. Electric models like the VEVOR Wet Tile Saw provide power and precision but require more setup and maintenance.

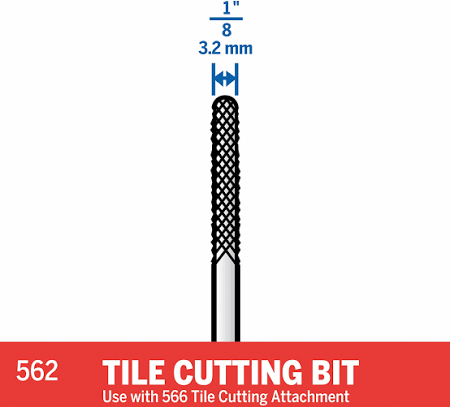

Blade Quality for Ceramic and Porcelain

- Diamond Blades: Ensure the cutter is equipped with a high-quality diamond blade suitable for the tile material, particularly for cutting porcelain and ceramic tiles. Products like the DeWalt DWC860W Wet/Dry Tile Saw are designed for such tasks.

- Blade Adjustability: The ability to adjust blade height and angle can significantly impact the quality of the cut, especially for bevel cuts.

Portability and Size

- Compact Design: For those who need to transport their tile cutter frequently, a compact design like the QEP 12″ Vinyl Tile Cutter is ideal.

- Lightweight Models: Consider the weight of the tile cutter if it needs to be moved regularly. Portable models like the Sigma 7F Standard 14′′ Pull Handle Tile Cutter offer a good balance between functionality and ease of movement.

Selecting the right tile cutter depends on a combination of factors including the type of tiles you work with, the scale of the projects, and your specific needs for precision and portability. Features like robust construction, precision cutting capabilities, and ease of use should guide your decision to ensure that you invest in a tool that will meet your tiling needs effectively and efficiently.

How to Use a Tile Cutter Machine: Step-by-Step Guide

Using a tile cutter machine effectively requires careful preparation of the tile and the cutting surface to ensure precision and avoid damage. Here’s a comprehensive guide on how to prepare and execute tile cutting using a tile cutter.

Preparing the Tile and Surface

Step 1: Choose the Right Tile Cutter

- Selection Criteria: Based on the type of tile (ceramic, porcelain, glass), select a tile cutter that best fits the material and the size of the tile. For larger tiles, consider a cutter with a wider cutting bed such as the Sigma 2D4 Professional Tile Cutter or the MUFASHA 70 Inch Large Manual Tile Cutter for its extended capacity.

- Product Link: For smaller projects or tighter spaces, a more compact model like the QEP 20 in. Tile Cutter may be appropriate.

Step 2: Prepare the Workspace

- Clean Surface: Ensure your cutting surface is flat and clean. Remove any debris or dust that might interfere with the precision of the cut.

- Stable Setup: Secure the tile cutter on a stable surface to prevent any movement during the cutting process. Use a non-slip mat underneath if necessary.

Step 3: Measure and Mark the Tile

- Measuring Tools: Use a straight edge or a measuring tape along with a tile scribe to mark where you will cut the tile. Ensure your measurements are precise to avoid waste and ensure a clean installation.

- Marking the Tile: Use a felt-tip pen or a grease pencil for clear visibility of the cut line.

Step 4: Scoring the Tile

- Scoring Process: Place the tile firmly against the guide of the tile cutter. Adjust the scoring wheel to ensure it aligns with the marked line. Push or pull the lever (depending on the model) to score the tile once with moderate pressure to create a clear incision.

- Tip: Do not score the tile multiple times as this can lead to uneven breaks.

Step 5: Snapping the Tile

- Snapping Mechanism: After scoring, most tile cutters have a snapping mechanism. Align the scored line with the snapping ridge and press down firmly on the handle or press the snapping button to divide the tile along the scored line.

- Check Results: Inspect the tile to ensure a clean, straight cut. If the edge is not as desired, use a tile file to smooth out any roughness.

Step 6: Final Adjustments

- Smoothing Edges: For any small inaccuracies or rough edges, use a glass cutter tool or sanding stone to refine the finish, especially if the tile will be visible at the edge of the installation area.

Properly preparing the tile and your workspace is crucial for successful tile cutting. Using a high-quality tile cutter like those from Sigma or Vevor, equipped with sharp blades and stable bases, can significantly enhance the accuracy and cleanliness of your cuts. Always wear appropriate safety gear, such as gloves and eye protection, to prevent injuries during the cutting process.

By following these steps, you can achieve professional-level results in your tiling projects, ensuring that each piece fits perfectly and the overall finish is aesthetically pleasing and durable.

How to Use a Manual Tile Cutter: A Comprehensive Guide

Manual tile cutters are a staple in the toolkits of DIY enthusiasts and professional tilers alike. They offer a quick, clean way to cut tiles without the noise and dust associated with power tools. Here’s a detailed guide on how to effectively use a manual tile cutter.

Step 1: Setting Up Your Workspace

Prepare the Area

- Ensure your workspace is flat and stable. Use a workbench or a sturdy table that can support the size and weight of your tiles and tile cutter.

- Place a non-slip mat under the tile cutter to prevent any movement during operation.

Safety First

- Wear safety glasses to protect your eyes from tile chips.

- Consider wearing gloves to prevent cuts from sharp tile edges.

Step 2: Preparing the Tile

Measure and Mark

- Measure the area where the tile will be placed and determine the size needed.

- Use a straight edge and a pencil or a marker to draw the cut line directly on the tile surface.

Scoring the Tile

- Place the tile on the cutter, aligning the cut line with the cutting wheel.

- Lower the cutting handle and apply even pressure to score the tile from one end to the other in one smooth motion. The goal is to create a deep enough score that will ensure a clean snap.

Step 3: Making the Cut

Snapping the Tile

- After scoring, lift the handle and reposition the tile so the scored line aligns with the breaking point.

- Press down on the handle to snap the tile along the scored line. This step requires firm pressure but should not be forceful enough to crush the tile.

Step 4: Finishing Touches

Smoothing the Edges

- Use a tile file or sandpaper to smooth out any rough edges along the cut line to prevent any sharpness that could lead to cuts during installation.

Recommended Products

Manual Tile Cutters for Different Tile Types

- Sigma 2B3 25 inch Tile Cutter: Ideal for precise cuts on both ceramic and porcelain tiles.

- QEP 12″ Vinyl Tile Cutter: Best suited for softer tile materials like vinyl or laminate.

Enhancing Your Cutting Experience

- Sigma TC2B3 26″ Pull Tile Cutter: Features a pull handle which makes scoring smoother, perfect for larger tiles.

- VEVOR Manual Tile Cutter Single Rail: Known for its durability and ease of use, suitable for a variety of tile types.

Using a manual tile cutter effectively requires careful preparation and precise execution. By following these steps, you can achieve professional-quality cuts that will make your tiling project look seamless and beautiful. Always remember to prioritize safety by wearing the appropriate protective gear and working in a well-prepared environment. For specific product needs, consider the recommended tile cutters which are designed to handle different materials and tile sizes, ensuring that your project results are as accurate and high-quality as possible.

Operating a Tile Cutter Machine: Step-by-Step Guide

Tile cutter machines are powerful tools designed to handle precise and efficient tile cuts, whether you’re working with ceramic, porcelain, or other materials. This guide outlines the process of operating a tile cutter machine and achieving a clean break using a tile snapper.

1. Setting Up the Tile Cutter Machine

Prepare Your Workspace

- Place the tile cutter machine on a stable, flat surface. Machines like the Sigma 2D4 Professional Tile Cutter are designed for stability but should still be on a secure base.

- Ensure the cutting area is clean and free of debris to prevent any misalignment.

Inspect the Machine

- Check the cutting wheel for sharpness and proper alignment.

- Make sure all moving parts are well-lubricated and functioning smoothly.

2. Preparing the Tile

Measure and Mark

- Use a measuring tape and a pencil to mark the cutting line on the tile surface.

- For precise measurements, tools like a tile scribe or ruler are essential.

Position the Tile

- Place the tile on the cutting bed, aligning the marked line with the cutting guide on the machine.

- Use the machine’s clamps, if available, to secure the tile in place to avoid movement.

3. Scoring the Tile

Using the Cutter

- Lower the cutting handle until the blade lightly touches the tile.

- Push or pull the handle, depending on the machine type, with consistent pressure along the marked line.

- Machines like the VEVOR Manual Tile Cutter Cutting Machine with Infrared include infrared guides for accuracy.

Check the Score Line

- Ensure the scored line is continuous and deep enough to create a clean break during snapping.

4. Achieving a Clean Break with a Tile Snapper

Align for Breaking

- Position the tile so the scored line aligns with the breaking mechanism of the tile cutter.

- Apply downward pressure using the machine’s handle or breaker bar.

Breaking the Tile

- For a clean snap, ensure even pressure is applied across the tile. Machines like the Sigma Kera-Cut Extendable 8AE2 are ideal for handling large-format tiles.

5. Final Touches

Smoothing Edges

- Use a tile file or sandpaper to smooth any rough edges.

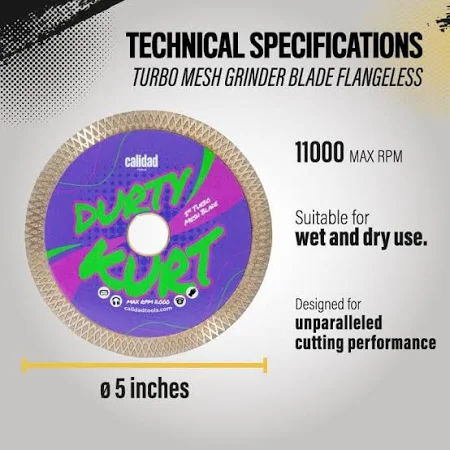

- For ceramic and porcelain tiles, high-quality diamond pads or a Calidad Turbo Diamond Saw Blade can help refine cuts.

Inspect the Cut

- Confirm that the tile dimensions are correct and the edges are clean.

- Make additional cuts if necessary.

Pro Tips for Precision and Safety

- Choose the Right Machine: For heavy-duty projects, opt for a machine like the Vevor Tile Cutter 48 Inch Double Rail.

- Blade Maintenance: Ensure the cutting wheel is sharp. Replace it regularly for optimal performance.

- Work Slowly: Rushing increases the risk of uneven cuts or tile breakage.

- Use Safety Gear: Always wear safety glasses and gloves to protect against tile shards.

Table: Comparison of Tile Cutter Machines for Clean Breaks

| Product | Key Features | Ideal For | Link |

|---|---|---|---|

| Sigma 2D4 Professional Tile Cutter | Precision cutting, large tile support | Porcelain, ceramic tiles | View Here |

| VEVOR Manual Tile Cutter | Infrared guidance, ergonomic design | Porcelain tiles | View Here |

| Muzata Tile Cutter | Large format tiles, heavy-duty build | Large tiles, precision cuts | View Here |

Cutting Long Tiles vs. Small Tiles: A Comprehensive Guide

Cutting tiles accurately is essential for achieving a professional finish, especially when dealing with tiles of varying sizes. The tools, techniques, and considerations differ when working with long tiles versus small tiles. This guide covers the best practices and tools for each scenario, helping you select the right tile cutting tools and ensuring precise results.

Cutting Long Tiles

Long tiles are commonly used for modern flooring and wall designs, requiring precision and stability during the cutting process.

Challenges of Long Tile Cutting

- Maintaining straight cuts over a long distance.

- Preventing the tile from snapping unevenly.

- Supporting the weight of large tiles during the cutting process.

Essential Tools for Long Tiles

- Vevor Tile Cutter 48 Inch Double Rail: A robust tool designed for large-format tiles, ensuring stability and accuracy.

- Sigma Kera-Cut Extendable 8AE2: Ideal for cutting oversized porcelain and ceramic tiles with precision.

- Wet Tile Saw: For intricate cuts or heavy-duty materials like stone or granite tiles, a wet saw such as the VEVOR Wet Tile Saw 7-inch is recommended.

Step-by-Step Process

Mark the Tile:

- Use a pencil and ruler or laser guide for accurate markings.

- Double-check the measurements, especially for long tiles.

Secure the Tile:

- Place the tile firmly on the cutting platform.

- Machines like the TILER 48 Inch Manual Tile Cutter include adjustable clamps for better stability.

Score the Tile:

- Apply consistent pressure along the entire length using a scoring wheel. Tools like the Muzata 48 Inch Manual Tile Cutter are perfect for this.

Snap the Tile:

- Use the breaking mechanism to snap the tile cleanly. Ensure even pressure is applied to prevent chipping.

Finish the Edges:

- Smooth any rough edges with a tile file or a diamond blade tool such as the Diablo 4-1/2 in. Diamond Turbo Masonry Cut Off.

Cutting Small Tiles

Small tiles, often used for intricate designs like mosaics or backsplashes, demand precision and delicate handling.

Challenges of Small Tile Cutting

- Avoiding tile breakage due to excessive pressure.

- Managing detailed cuts for custom shapes or patterns.

Essential Tools for Small Tiles

- Vitrex Handheld Tile Cutter: A lightweight option for intricate cuts on small tiles.

- Manual Tile Cutter: Models like the Whizmax Manual Tile Cutter offer excellent precision for smaller projects.

- Tile Scribe Tool: Ideal for scoring small cuts or making minor adjustments.

Step-by-Step Process

Mark the Tile:

- Use a fine-tipped marker for detailed designs.

- For mosaics, align the tile pieces with the overall pattern before cutting.

Position the Tile:

- Place the tile on the cutter, aligning the scoring wheel with the marked line.

- Secure it gently to avoid damaging the tile.

Score the Tile:

- Apply light and even pressure. Tools like the Faithfull Hand DIY Tile Cutter TCT Tipped are excellent for delicate scoring.

Snap the Tile:

- Use a tile snap cutter for clean breaks. For intricate shapes, a handheld cutter or saw may be needed.

Smooth the Edges:

- Use sandpaper or a diamond file to refine the edges.

Comparison: Cutting Long Tiles vs. Small Tiles

| Aspect | Long Tiles | Small Tiles |

|---|---|---|

| Tools Required | Large manual cutters, wet saws | Handheld cutters, manual cutters, tile scribes |

| Precision | Requires laser guides or clamps for accuracy | Easier to handle but demands precision for intricate designs |

| Material Handling | Difficult due to weight and size | Easier to maneuver and cut |

| Breakage Risk | High if not properly supported | Low but requires careful scoring |

| Best Tool Example | Rubi Hit N 48″ Professional Tile Cutter | Marshalltown HTC Handheld Tile Cutter |

Pro Tips for Success

- Choose the Right Blade: Use a Calidad Turbo Diamond Saw Blade for long tiles to maintain sharpness and precision.

- Work Slowly: Rushing can cause uneven cuts or tile breakage.

- Support Long Tiles: Use additional supports to prevent bending during scoring.

- Plan Ahead: For mosaics or intricate patterns, pre-cut the tiles using a tile scribe tool for minimal errors.

Best Tile Cutter Machines in the Market

Selecting the right tile cutter machine is critical for achieving professional-grade results in tile cutting, whether for flooring, backsplash, or intricate designs. With a variety of manual tile cutters, wet tile saws, and specialized tile cutting tools available, this guide highlights some of the best options tailored to different needs and applications.

Top Manual Tile Cutter Machines

Manual tile cutters are perfect for cutting ceramic and porcelain tiles with precision and ease. They are ideal for DIY projects or professional installations where portability and affordability are crucial.

1. Rubi Speed Plus Tile Cutter

- Best For: Quick and efficient straight cuts on ceramic and porcelain tiles.

- Features:

- Robust aluminum construction for durability.

- Double guide system for accurate visibility during cutting.

- Easy-to-use scoring wheel for smooth operation.

- Use Case: Ideal for small-to-medium tile projects like bathroom walls and backsplashes.

2. 65-Inch Manual Tile Cutter

- Best For: Large-format tiles up to 65 inches in length.

- Features:

- Heavy-duty rails and precise scoring wheel for long, straight cuts.

- Adjustable measurements for consistency across multiple tiles.

- Use Case: Perfect for large flooring projects and oversized ceramic or porcelain tiles.

3. Sigma Series 4 NEX Push Tile Cutter

- Best For: Precision cutting of porcelain and ceramic tiles.

- Features:

- Push handle design for smooth scoring.

- Built-in measurement system for quick adjustments.

- Ergonomic design for extended use.

- Use Case: Suitable for professional tile installers working on detailed designs or larger-scale projects.

Top Wet Tile Saws

For cutting tougher materials like natural stone or for intricate cuts, wet tile saws are essential. They offer cleaner edges and reduce dust.

1. SKIL 3540-02 7-Inch Wet Tile Saw

- Best For: DIY enthusiasts and small home improvement projects.

- Features:

- Rust-resistant stainless steel table.

- Adjustable rip fence with miter gauge for precise cuts.

- 7-inch diamond blade for durability.

- Use Case: Great for bathroom tiles, mosaics, and small porcelain tiles.

2. DeWalt D24000R 10-Inch Wet Tile Saw

- Best For: Heavy-duty professional use.

- Features:

- Powerful 1.5 HP motor for smooth operation.

- Dual water nozzles to minimize dust and debris.

- Sliding table for precise rip cuts.

- Use Case: Ideal for large commercial projects requiring frequent and precise tile cuts.

3. RIDGID 9-Amp 7-Inch Portable Wet Saw

- Best For: Portability combined with power.

- Features:

- Foldable stand for easy transportation.

- Angled cutting capability for beveled edges.

- Anti-splash system for a clean work area.

- Use Case: Perfect for contractors who need portability without sacrificing performance.

Specialized Tile Cutting Tools

1. DEWALT DWC860W Wet/Dry Handheld Tile Cutter

- Best For: Curved and intricate cuts on porcelain, stone, and granite.

- Features:

- 10.8-amp motor for powerful cutting.

- Adjustable depth guide for versatile applications.

- Can operate wet or dry for different materials.

- Use Case: Ideal for creating custom designs, such as medallions or detailed borders.

2. QEP Tile Pliers

- Best For: Mosaic and small tile cutting.

- Features:

- Compact size for easy handling.

- Perfect for shaping small tiles or adjusting edges.

- Use Case: A must-have for creating intricate patterns in backsplashes or mosaic art.

Comparison Table: Top Tile Cutters

| Tile Cutter | Type | Best For | Key Feature | Use Case |

|---|---|---|---|---|

| Rubi Speed Plus Tile Cutter | Manual | Medium-sized tiles | Double guide system for precision | Bathroom and kitchen backsplashes |

| DeWalt D24000R 10-Inch Wet Tile Saw | Wet Tile Saw | Professional-grade projects | Sliding table for long rip cuts | Large flooring and commercial projects |

| 65-Inch Manual Tile Cutter | Manual | Large-format tiles | Adjustable for long tiles | Large floor tiling projects |

| DEWALT DWC860W Wet/Dry Handheld Tile Cutter | Handheld Cutter | Custom and intricate cuts | Wet/dry operation for versatile applications | Borders, medallions, and decorative tiles |

| SKIL 3540-02 7-Inch Wet Tile Saw | Wet Tile Saw | DIY home projects | Compact design for small spaces | Backsplashes and mosaic tiles |

Factors to Consider When Choosing a Tile Cutter Machine

Tile Material:

- For ceramic tiles, a manual tile cutter like the Rubi TS-MAX Tile Cutter is sufficient.

- For stone or granite tiles, opt for a wet tile saw.

Project Size:

- Small-scale projects: SKIL 3540-02 7-Inch Wet Tile Saw.

- Large-scale flooring: RIDGID 9-Amp 7-Inch Portable Wet Saw.

Cutting Precision:

- For straight cuts, manual cutters with built-in guides are excellent.

- For detailed work, handheld tile cutters or pliers are ideal.

Portability:

- Contractors on the move may prefer the RIDGID 6.5 Amp Corded Tabletop Wet Tile Saw for its compact size and portability.

With the right tile cutter machine, you can ensure accuracy, efficiency, and professional-quality results for any tiling project.

Top Portable Tile Cutter Models

Portable tile cutter machines are essential for contractors and DIY enthusiasts who need mobility and efficiency in their tile-cutting tasks. Here are the top portable tile cutter models, categorized based on their performance and features.

1. RIDGID 9-Amp 7-Inch Portable Wet Saw Tile Cutter with Stand

- Best For: Professional contractors on the go.

- Features:

- Foldable stand for easy transport and storage.

- A 9-amp motor capable of cutting through tough materials.

- 7-inch diamond blade with an anti-splash system for a clean workspace.

- Portability Factor: Lightweight and comes with a collapsible stand for hassle-free portability.

- Use Case: Large-scale tile installations where portability and power are critical.

2. RYOBI 7-Inch Tabletop Tile Saw

- Best For: Compact projects requiring precise cuts.

- Features:

- A lightweight tabletop design.

- Splash guard and adjustable rip fence for accuracy.

- Ideal for straight and angled cuts.

- Portability Factor: Compact enough to carry and set up in small spaces.

- Use Case: Perfect for backsplash tiles and medium-sized ceramic tiles.

3. DeWalt D24000R 10-Inch Wet Tile Saw

- Best For: Versatile cutting with high precision.

- Features:

- Dual water nozzles to control overspray.

- Sliding table for extended rip capacity.

- 10-inch blade suitable for larger tiles and stone materials.

- Portability Factor: Integrated wheels and lightweight design make it portable for professionals.

- Use Case: Flooring and wall tiles, including stone and porcelain.

Recommended Manual Tile Cutters

Manual tile cutters are simple yet effective tools for clean, straight cuts on ceramic and porcelain tiles. Here are some of the best models for precision and durability.

1. Rubi Speed Plus Tile Cutter

- Best For: Quick cuts for ceramic and porcelain tiles.

- Features:

- Dual rail system for enhanced cutting visibility.

- Lightweight aluminum build for easy portability.

- Scoring wheel ensures clean, precise cuts.

- Use Case: Ideal for small-to-medium tiling projects such as bathrooms or kitchens.

2. 65-Inch Manual Tile Cutter

- Best For: Large-format tiles.

- Features:

- Heavy-duty construction to handle large tiles.

- Extended measurement guides for consistent cuts.

- Use Case: Designed for large flooring projects involving oversized tiles.

3. Sigma Series 4 NEX Push Tile Cutter

- Best For: High precision in professional-grade projects.

- Features:

- Push handle design for ergonomic operation.

- Advanced scoring system for flawless cuts on hard porcelain.

- Use Case: Suitable for contractors working on high-end tile installations.

Best Ceramic Tile Cutting Tools

Ceramic tiles are among the most commonly used materials in tiling projects. Using the right ceramic tile cutter tools ensures smooth, precise results without chipping.

1. Anvil Tile Cutter 14-Inch Ceramic and Porcelain

- Best For: Affordable yet reliable tile cutting.

- Features:

- Compact design for portability.

- Adjustable measurement guides for repeatable cuts.

- Use Case: Ideal for DIY projects and small ceramic tile jobs.

2. DEWALT DWC860W Wet/Dry Handheld Tile Cutter

- Best For: Intricate cuts in ceramic and other materials.

- Features:

- A 10.8-amp motor for cutting through thick tiles.

- Wet/dry operation for versatility.

- Adjustable cutting depth for custom designs.

- Use Case: Perfect for custom patterns, medallions, and small tile adjustments.

3. QEP Tile Pliers

- Best For: Mosaic and intricate tile adjustments.

- Features:

- Compact size for easy handling.

- Designed for shaping and breaking small ceramic tiles.

- Use Case: Essential for mosaic art and detailed backsplash designs.

Comparison Table: Portable vs. Manual vs. Ceramic Cutting Tools

| Model | Type | Best For | Key Feature | Use Case |

|---|---|---|---|---|

| RIDGID 9-Amp 7-Inch Wet Saw | Portable Wet Tile Saw | Large-scale projects | Foldable stand and powerful motor | Flooring and commercial tiles |

| 65-Inch Manual Tile Cutter | Manual Tile Cutter | Large-format tiles | Extended measurement guides | Large flooring projects |

| Anvil Tile Cutter | Ceramic Tile Cutter | Small ceramic tiles | Lightweight and affordable | Small home improvement projects |

| DEWALT DWC860W Handheld Cutter | Handheld Tile Cutter | Custom intricate cuts | Wet/dry operation with depth adjustment | Borders, medallions, and designs |

| Rubi Speed Plus Tile Cutter | Manual Tile Cutter | Quick straight cuts | Dual rail system for accuracy | Bathrooms and kitchens |

Choosing the Right Tile Cutter Tool

- For portability: Choose a lightweight model like the RYOBI 7-Inch Tabletop Tile Saw.

- For precision manual cutting: Opt for models like the Sigma Series 4 NEX Push Tile Cutter.

- For ceramic tiles: Affordable options like Anvil Tile Cutter deliver smooth results.

These recommended tile cutter machines and tools cater to various needs, ensuring you achieve professional-grade results for any tile installation project.

Tile Cutting Tips for Different Applications

When cutting tiles for different applications, using the correct tools and techniques is crucial to achieve clean, professional results. Below are expert tips for handling various types of tiles and specific scenarios.

Cutting Ceramic Tiles

Ceramic tiles are versatile and commonly used in flooring and wall applications. To achieve precise cuts:

Tools Needed:

- Anvil Tile Cutter 14-Inch Ceramic and Porcelain for small projects.

- DeWalt D24000R 10-Inch Wet Tile Saw for larger projects requiring precise edge finishes.

Steps:

Measure and Mark:

- Use a pencil or a tile marker to mark the desired cutting line.

- For curved cuts, create a template using cardboard.

Choose the Right Tile Cutter:

- For straight cuts: Use a tile cutter machine like the Rubi TS-MAX Tile Cutter.

- For intricate cuts: Use a handheld cutter like the DEWALT DWC860W Wet/Dry Handheld Tile Cutter.

Cut with Precision:

- Score the tile along the marked line.

- Apply firm pressure to snap the tile using a tile snap cutter.

Pro Tip:

- Wet cutting ensures a smooth finish and reduces dust generation.

Cutting Backsplash Tiles

Backsplash tiles are often smaller and may include mosaic patterns or delicate finishes.

Tools Needed:

- Rubi Speed Plus Tile Cutter for quick, precise cuts.

- Tile pliers like QEP Tile Pliers for detailed adjustments.

Steps:

- Secure the Tile:

- Place the backsplash tile on a flat surface, ensuring stability.

- Use a Small Tile Cutter:

- A 65-Inch Manual Tile Cutter is ideal for long, narrow backsplash tiles.

- Cut Carefully:

- Score along the line using a manual tile cutter.

- Snap the tile gently to prevent cracking.

- Shape and Trim:

- For complex edges, use a handheld grinder or tile cutter hand tool.

Pro Tip:

- Always measure backsplash tiles twice before cutting, as irregularities in walls can cause alignment issues.

Cutting Bathroom and Floor Tiles

Bathroom and floor tiles are typically thicker and more durable. Cutting them requires powerful tools for precision.

Tools Needed:

- RIDGID 9-Amp 7-Inch Wet Saw for tough porcelain or stone tiles.

- Brutus 20″ Tile Cutter for general floor tile cutting.

Steps:

Plan the Cuts:

- Measure the area and mark each tile accordingly.

- Allow space for grout joints.

Use the Right Cutter:

- For long cuts, use a wet tile saw like the Diamondback 15 Amp 10-Inch Wet Tile Saw.

- For straight cuts, a manual tile cutter works effectively.

Handle Edges:

- Use a tile scribe to smooth sharp edges for a polished finish.

Break and Snap:

- Use a tile snap cutter for quick results on floor tiles like ceramic or porcelain.

Pro Tip:

- Wet saws are recommended for bathroom tiles to ensure clean edges and minimize the risk of cracking.

Using a Dry Tile Cutter

Dry tile cutters are effective for quick, dust-free cutting in outdoor or well-ventilated areas.

Tools Needed:

- Marshalltown HTC Handheld Tile Cutter for smaller tiles.

- Roberts Vinyl Tile Cutter 10-900 for precision cuts on vinyl tiles.

Steps:

Prepare the Workspace:

- Use a sturdy table or bench to support the tile.

- Ensure the cutting area is clear of obstructions.

Score and Snap:

- Mark the tile using a pencil.

- Score the surface using a dry tile cutter with a carbide scoring wheel.

- Apply firm, even pressure to snap the tile.

Polish the Edges:

- Use a sanding stone or tile cutting tool to smooth rough edges.

Pro Tip:

- A dry tile cutter is best for ceramic and porcelain tiles in smaller projects or when wet cutting is not feasible.

Comparison of Tile Cutting Applications

| Application | Best Tool | Pro Tip |

|---|---|---|

| Cutting Ceramic Tiles | DeWalt D24000R Wet Tile Saw | Use wet cutting to minimize chipping. |

| Cutting Backsplash Tiles | Rubi Speed Plus Tile Cutter | Double-check measurements to prevent alignment issues. |

| Cutting Floor Tiles | Brutus 20″ Tile Cutter | Use a wet saw for larger, thicker tiles. |

| Dry Tile Cutting | Marshalltown HTC Handheld Tile Cutter | Operate in a well-ventilated area to reduce dust accumulation. |

These tile cutting tips and recommended tools ensure precision and efficiency for various tile types and applications.

Tile Cutting Tools You Should Know About

Tile cutting tools are essential for achieving precise cuts and professional results. Whether you’re working with ceramic, porcelain, or mosaic tiles, selecting the right tool for the job is crucial. Below, we dive into some of the best tools available for specific cutting needs.

Tile Breakers and Snappers

Tile breakers and snappers are indispensable for straight cuts on ceramic and porcelain tiles. They are designed to score and snap tiles cleanly with minimal effort.

Top Tools for Tile Breaking:

- QEP Brutus Tile Cutter: Known for its precision and robust design, this manual tile cutter is perfect for both DIYers and professionals.

- 20″ Brutus Tile Cutter: Ideal for medium-sized tiles, this tool delivers clean cuts with minimal chipping.

How They Work:

- Place the tile on the cutting platform.

- Score the tile using the integrated carbide wheel.

- Apply pressure using the snapping mechanism to break the tile cleanly.

Applications:

- Straight cuts for ceramic and porcelain tiles.

- Quick adjustments for on-site projects.

Pro Tip:

Use a tile snap cutter for jobs requiring portability and ease of use, such as backsplash tile installations.

Tile Scribes and Hand Tools

For intricate or detailed cuts, tile scribes and hand tools provide unmatched control. These tools are especially useful for small-scale or decorative projects.

Recommended Tile Scribes:

- QEP Tile Pliers: Perfect for making tiny adjustments to tiles without the need for a full cutter.

- Marshalltown HTC Handheld Tile Cutter: A versatile tool for straight and curved cuts on ceramic tiles.

Steps for Using Tile Scribes:

- Mark the tile where you want the cut.

- Use the scribe to score the tile along the marked line.

- Snap the tile along the scored line or use tile pliers for finer adjustments.

Best Use Cases:

- Cutting mosaic tiles for backsplashes.

- Creating custom shapes for intricate patterns.

Pro Tip:

A tile cutter hand tool like the Faithfull Hand DIY Tile Cutter is an affordable solution for homeowners tackling DIY tile projects.

Cortadora de Tile (Manual and Electric)

The term cortadora de tile refers to manual and electric tile cutters designed for professional-grade cutting. These tools cater to larger tiles and deliver highly accurate cuts.

Top Cortadoras de Tile:

- Manual:

- Sigma Series 4 NEX Push Tile Cutter: Known for its ergonomic design and high precision.

- 65 Inch Manual Tile Cutter: Ideal for cutting larger tiles up to 65 inches.

- Electric:

- SKIL 3540-02 7-Inch Wet Tile Saw: A compact yet powerful electric tile cutter machine for wet cuts.

- DeWalt D24000R 10-Inch Wet Tile Saw: A high-performance option for large-scale projects.

Advantages of Electric Cortadoras:

- Efficiently cut through thicker materials like granite or marble.

- Ensure a clean finish with minimal effort.

Pro Tip:

For large-scale tiling projects, consider an electric tile cutting machine to save time and ensure precision.

Long Tile Cutters for Large Tiles

Long tile cutters are essential for handling large-format tiles used in modern flooring and wall designs. These tools accommodate tiles up to 65 inches or more, providing the capacity needed for oversized materials.

Recommended Long Tile Cutters:

- Muzata Tile Cutter 48 Inch: A versatile manual tile cutter for large porcelain tiles.

- Diamondback 15 Amp 10-Inch Wet Tile Saw: Designed for precision on long, thick tiles.

- Sigma Kera-Cut Extendable Tile Cutter: A professional-grade cutter for cutting tiles beyond 70 inches.

Benefits of Long Tile Cutters:

- Designed to handle the weight and length of large tiles.

- Provide straight, smooth edges for professional results.

Applications:

- Ideal for cutting tiles used in large flooring projects.

- Commonly employed for oversized bathroom or kitchen tiles.

Pro Tip:

Choose a manual tile cutter like the Rubi TS-MAX Tile Cutter for jobs that demand portability without sacrificing precision.

Comparison Table of Tile Cutting Tools

| Tool | Best For | Recommended Model |

|---|---|---|

| Tile Breakers & Snappers | Straight cuts on ceramic tiles | QEP Brutus Tile Cutter |

| Tile Scribes & Hand Tools | Intricate cuts and small adjustments | Marshalltown HTC Handheld Tile Cutter |

| Cortadora de Tile (Manual) | Professional manual cuts | Sigma Series 4 NEX Push Tile Cutter |

| Cortadora de Tile (Electric) | High-volume cutting tasks | SKIL 3540-02 7-Inch Wet Tile Saw |

| Long Tile Cutters | Large-format tiles | Sigma Kera-Cut Extendable Tile Cutter |

By selecting the right tile cutting tools, you can achieve professional-grade results across a variety of applications, from simple DIY projects to complex professional installations.

Tile Cutter Machine vs. Manual Tile Cutters

Choosing between a tile cutter machine and a manual tile cutter depends on the scope and requirements of your project. Both tools have their strengths and limitations, making them suited for specific applications. This guide delves into the pros and cons of each, with recommendations to help you make an informed decision.

Pros and Cons of Tile Cutter Machines

Pros:

- Precision Cutting: Electric tile cutter machines, such as the DeWalt D24000R 10-Inch Wet Tile Saw, deliver unmatched accuracy, especially for intricate shapes and miters.

- Effortless Performance: The motorized blade minimizes manual effort, cutting through thick tiles like granite and porcelain with ease.

- Versatility: Suitable for straight cuts, angled cuts, and beveling, as seen in the RIDGID 9-Amp 7-Inch Portable Wet Saw.

- Efficiency for Large Jobs: Best for high-volume tasks or cutting large-format tiles, such as those used in modern flooring projects.

Cons:

- Cost: Tile cutter machines are generally more expensive than manual cutters.

- Setup Time: They require water for cooling (wet tile saws) and may take longer to set up.

- Portability: Bulky and heavier, making them less convenient for on-the-go projects.

- Maintenance: Regular blade replacements and cleaning are necessary for optimal performance.

Pros and Cons of Manual Tile Cutters

Pros:

- Portability: Lightweight and compact, manual tile cutters like the Rubi Speed Plus Tile Cutter are ideal for transport.

- Cost-Effective: Affordable compared to electric machines, making them accessible for DIYers and smaller projects.

- Quick Setup: No need for electricity or water, offering a straightforward and fast cutting process.

- Durability: Simple mechanisms result in fewer parts to break or maintain.

Cons:

- Limited Precision: Less accurate than machines, particularly for intricate or curved cuts.

- Effort-Intensive: Requires manual scoring and snapping, which can be challenging for harder tiles like porcelain.

- Material Restrictions: Not ideal for cutting thick or large tiles.

When to Use a Manual Tile Cutter

Manual tile cutters are best suited for:

- Small Projects: Ideal for DIY tasks such as backsplashes or bathroom renovations.

- Straight Cuts: Effective for cutting standard ceramic tiles along straight lines.

- Portability Needs: Perfect for situations where mobility is key, such as outdoor or remote job sites.

- Budget Constraints: For those looking for an economical option.

Recommended Models:

- QEP Brutus Tile Cutter: Known for its reliability and clean cuts.

- Rubi TS-MAX Tile Cutter: Provides precise scoring for ceramic and porcelain tiles.

- Sigma Series 4 NEX Push Tile Cutter: Designed for professionals who need a lightweight, high-performance manual cutter.

When to Invest in a Tile Cutting Machine

A tile cutter machine is essential for:

- Large-Scale Projects: Ideal for contractors handling high-volume tile installations or large-format tiles.

- Intricate Cuts: Electric machines can achieve beveled, curved, or angled cuts with precision.

- Hard Materials: Necessary for cutting thick tiles like porcelain, marble, or granite.

- Time-Sensitive Jobs: Faster cutting speeds make them more efficient for commercial tasks.

Recommended Models:

- SKIL 3540-02 7-Inch Wet Tile Saw: A great entry-level wet saw for precise cuts.

- Diamondback 15 Amp 10-Inch Wet Tile Saw: Perfect for handling large tiles with extended rip capacity.

- RIDGID 6.5 Amp Corded Table Top Wet Tile Saw: Compact yet powerful for both DIYers and professionals.

Comparison Table

| Feature | Manual Tile Cutter | Tile Cutter Machine |

|---|---|---|

| Precision | Moderate | High |

| Best Use | Straight cuts, smaller projects | Large projects, intricate or thick tile cuts |

| Cost | Affordable | Expensive |

| Portability | Highly portable | Less portable due to size and weight |

| Ease of Use | Easy to use, requires manual effort | Easy for straight cuts, more setup time required |

| Material Compatibility | Ceramic, some porcelain | Ceramic, porcelain, marble, granite |

| Recommended Model | Rubi Speed Plus Tile Cutter | DeWalt D24000R Wet Tile Saw |

Pro Tips:

- For DIYers: Start with a manual tile cutter like the Project Source Tile Cutter Kit for affordability and ease of use.

- For Professionals: Invest in a durable tile cutter machine like the RIDGID 9-Amp 7-Inch Portable Wet Saw for long-term efficiency and versatility.

Common Problems and Solutions While Cutting Tiles

Cutting tiles can present challenges, especially for DIYers or even seasoned professionals tackling demanding projects. One common issue is dealing with uneven tile breaks, which can compromise the quality of your installation. Below, we explore key problems, their causes, and effective solutions.

Dealing with Uneven Tile Breaks

Uneven tile breaks are frustrating, often leading to wasted material and time. Whether you’re using a tile cutter machine or a manual tile cutter, understanding the root cause is critical.

Common Causes

- Incorrect Scoring Pressure: Uneven pressure during scoring can lead to jagged edges or incomplete breaks.

- Dull or Damaged Scoring Wheel: A worn-out scoring wheel struggles to create a clean line, affecting break quality.

- Improper Tile Placement: Misaligned tiles can break unpredictably, especially when snapped.

- Material Mismatch: Using a cutter not designed for the tile material, such as attempting to cut thick porcelain with a basic ceramic cutter.

Solutions for Uneven Breaks

1. Proper Scoring Technique

- Apply Even Pressure: Ensure consistent pressure while scoring to create a deep, clean line across the tile.

- Use High-Quality Cutters: Opt for reliable tools such as the Rubi Speed Plus Tile Cutter for precise scoring and snapping.

- Score Once: Avoid multiple passes, as these can weaken the break line and lead to uneven results.

2. Maintain Your Tools

- Replace worn scoring wheels regularly. Consider using a high-durability cutter like the Sigma Series 4 NEX Push Tile Cutter with replaceable scoring wheels.

- Keep the tool clean to ensure smooth operation. Dust and debris can interfere with the scoring mechanism.

3. Align Tiles Correctly

- Place the tile flush against the cutter guide. A product like the 65-Inch Manual Tile Cutter offers excellent alignment for large tiles.

4. Use a Tile Cutter Designed for the Material

- For thicker or harder materials, switch to a tile cutter machine like the DeWalt D24000R 10-Inch Wet Tile Saw to achieve clean cuts on porcelain and stone tiles.

- For softer tiles like ceramic, a manual tile cutter like the QEP Brutus Tile Cutter is sufficient.

Additional Tips

| Problem | Cause | Solution |

|---|---|---|

| Jagged Edges | Scoring wheel too dull | Replace scoring wheel with a high-quality one (e.g., in the Rubi TS-MAX Tile Cutter). |

| Tile Snaps Too Soon | Excessive snapping pressure | Apply gradual, firm pressure using a tile snap cutter for controlled breaks. |

| Chipped Corners | Misaligned tile or weak support | Ensure tiles are flush against the cutter guide. For small tiles, try a manual tile cutter. |

| Incomplete Breaks | Inconsistent scoring depth | Maintain steady scoring pressure. Use a tile cutter machine for precise cuts. |

Preventing Uneven Breaks with Proper Tools

1. Tile Cutter Machines for Precision

For large tiles or hard materials, tile cutter machines such as the RIDGID 9-Amp 7-Inch Portable Wet Saw are essential. They ensure clean and accurate cuts, minimizing errors and uneven edges.

2. Manual Tile Cutters for Simplicity

For small projects or softer tiles, manual cutters like the Rubi TS-43 Max Tile Cutter are lightweight and easy to handle, offering great control over straight cuts.

3. Tile Snappers for Quick Fixes

Tile snappers, such as the QEP Tile Pliers, are great for smaller tiles or on-the-spot adjustments, though they require precision during scoring.

Pro Tips for Avoiding Uneven Breaks

- Practice First: If you’re a beginner, practice scoring and snapping on scrap tiles.

- Choose the Right Blade: For wet saws, use diamond-tipped blades such as the Diamondback 15 Amp 10-Inch Wet Tile Saw for cleaner cuts.

- Keep Tiles Stable: Use clamps or guides to prevent movement during cutting.

- Inspect Tools Regularly: Check for wear and tear to avoid mishaps during cutting.

By implementing these tips and selecting the right tile cutting tools, you can minimize uneven tile breaks and ensure a professional finish in your tiling projects.

Preventing Tile Cracks

Tile cracks are a common challenge when working with tiles, particularly when cutting or installing them. Cracks compromise the aesthetics and durability of your project. Below, we explore the causes of tile cracks and provide actionable solutions for prevention.

Common Causes of Tile Cracks

- Improper Cutting Technique: Uneven pressure while cutting or snapping the tile can lead to cracks.

- Inadequate Scoring Depth: Failing to score the tile deeply enough before snapping creates weak break lines.

- Using the Wrong Tool: Mismatched tools for the tile type, such as using a manual tile cutter on thick porcelain tiles, can lead to cracking.

- Improper Tile Support: Inadequate support during the cutting process can cause the tile to flex and crack.

- Material Stress: Tiles can crack from over-tightened screws, uneven subfloors, or improper adhesive application during installation.

Steps to Prevent Tile Cracks

1. Choose the Right Cutting Tool

- For ceramic tiles, use a manual tile cutter like the Rubi Speed Plus Tile Cutter for accurate scoring and snapping.

- For porcelain tiles or thick materials, use a tile cutter machine such as the DeWalt D24000R 10-Inch Wet Tile Saw to ensure clean cuts without stressing the tile.

2. Score and Snap with Precision

- Even Scoring Pressure: Use consistent pressure while scoring. Tools like the Sigma Series 4 NEX Push Tile Cutter have adjustable scoring settings to suit different tile types.

- Single Pass Scoring: Avoid multiple scoring attempts, which can weaken the tile edge. One smooth, precise pass is ideal.

3. Support the Tile During Cutting

- Always support the tile along its length, especially when using manual cutters. A tool like the 65-Inch Manual Tile Cutter provides excellent stability for large tiles.

- For smaller tiles, ensure the base of the cutter or workbench is level to prevent uneven pressure.

4. Match the Tool to the Tile Type

| Tile Type | Recommended Tool |

|---|---|

| Ceramic | Manual tile cutters like the Anvil Tile Cutter 14-Inch Ceramic and Porcelain. |

| Porcelain | Wet tile saws such as the SKIL 3540-02 7-Inch Wet Tile Saw. |

| Glass Tiles | Use a glass cutter tool like the QEP Tile Pliers for delicate scoring and snapping. |

| Stone Tiles | High-power wet saws like the Diamondback 15 Amp 10-Inch Wet Tile Saw. |

5. Handle Dry Cutting with Care

- Dry tile cutters, such as the RIDGID 6.5 Amp Corded Table Top Wet Tile Saw, are ideal for quick cuts but may generate more stress on the tile. Keep the blade sharp and ensure proper alignment.

- Use diamond blades like the Calidad Turbo Diamond Saw Blades for smooth, crack-free dry cutting.

6. Installation Tips

- Level the Subfloor: Uneven subfloors exert stress on tiles, causing cracks. Use leveling compounds if necessary.

- Appropriate Adhesive: Use tile adhesive suited for the tile material. For example, flexible adhesives reduce stress on large-format tiles.

- Proper Grouting: Ensure grout joints are not too tight. Expansion gaps allow for slight tile movement, preventing cracks.

Pro Tips for Crack-Free Tile Cutting

- Replace Worn-Out Blades: Regularly replace scoring wheels or diamond blades to maintain cutting efficiency.

- Use Water Cooling for Wet Saws: Tools like the RIDGID 9-Amp Portable Wet Saw use water cooling to reduce heat and stress on tiles.

- Avoid Overloading Manual Cutters: For tiles above the capacity of manual cutters, switch to a machine-based tool like the VEVOR Wet Tile Saw.

Addressing Tile Cracks During Installation

If a tile cracks during installation:

- Stop Immediately: Remove the cracked tile to prevent further damage.

- Inspect the Area: Check for underlying issues like uneven adhesive or subfloor gaps.

- Re-cut with Precision: Use a properly calibrated tile cutter machine or a sharp manual tile cutter for replacement tiles.

Maintaining Your Tile Cutter Tool

Proper maintenance of your tile cutter tools is essential to ensure long-lasting performance, precise cuts, and smooth operation. Whether you are using a manual tile cutter, a wet saw, or a tile cutter machine, regular upkeep can prevent costly repairs or replacements.

Why Maintenance Matters

- Prolongs Tool Lifespan: Regular care ensures that the tile cutter stays in optimal working condition.

- Improves Cutting Accuracy: Clean and well-maintained tools cut tiles without chipping or cracking.

- Reduces Downtime: Prevent unexpected malfunctions during critical projects.

Daily Cleaning and Maintenance

1. Cleaning After Each Use

- Remove debris, tile dust, and residue immediately after completing a cutting session.

- Use a damp cloth to wipe down manual tile cutters like the QEP Brutus Tile Cutter.

- For wet saws, flush the water tray and remove any leftover slurry or sediment to keep the pump and blade clean.

2. Checking the Blade