A Diamond Tile Cutter refers to a tool or device equipped with a diamond-infused blade used primarily for cutting through various tile materials, including ceramic, porcelain, and stone. Diamond blades are engineered for precision and efficiency, offering clean cuts without damaging the delicate materials. These cutters can range from simple hand-held devices to complex, motorized machines like electric tile cutters and wet saws.

Key Features of Diamond Tile Cutters:

- Blade Material: Made with synthetic diamonds, which are the hardest materials available, embedded into the edge.

- Design Varieties: Available in different forms such as stationary tile saws, handheld saws, and angle grinders.

- Cutting Capacity: Capable of making straight, diagonal, and curved cuts with ease.

Why Use Diamond Blades for Tile Cutting?

Diamond blades are preferred for tile cutting due to their unparalleled hardness and cutting precision. Here’s why they stand out:

- Durability: Diamond tile blades are incredibly durable, capable of cutting through the toughest materials without frequent replacements.

- Precision Cutting: They produce clean, precise cuts that minimize the risk of breakage, which is crucial when working with expensive materials like porcelain or marble.

- Versatility: Suitable for both wet and dry cutting applications, diamond blades can be used in various cutters, including circular saws, grinders, and specialized tile cutting machines.

Benefits in Bullet Points:

- Efficiency: Reduces the time spent on cutting due to superior cutting speed.

- Cost-Effective: Although initially more expensive, their longevity and efficiency save money in the long run.

- Less Dust and Debris: Especially when used in wet cutting conditions, diamond blades produce less airborne dust.

Choosing the Right Diamond Blade

Selecting the appropriate diamond blade for your tile cutter involves understanding the specific needs of your project:

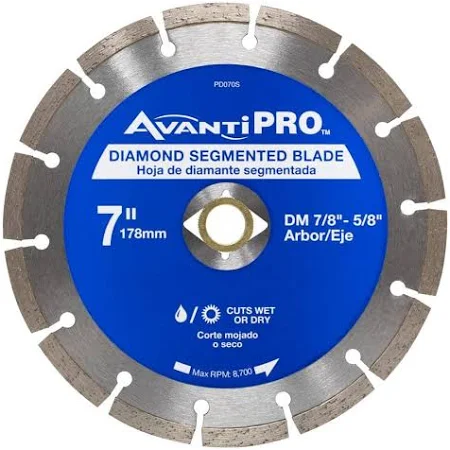

- Blade Type: Choose between continuous rim blades (for clean cuts in ceramic and porcelain) and segmented rim blades (for faster cuts in marble and granite).

- Size and Compatibility: Ensure the blade fits your tile cutter model, whether it’s a small tile cutter or a more robust 48-inch tile cutter.

- Wet vs. Dry Cutting: Wet blades require water to cool and lubricate the cut, ideal for large format tile cutters, whereas dry blades are better suited for quick jobs or outdoor use.

Popular Products in the Market

Some notable diamond tile cutters and blades include:

- MK Diamond MK-101: Renowned for its durability and precision, ideal for cutting large tiles.

- DeWalt D24000S: A robust electric tile cutter that offers both power and portability.

- Bosch DB743S: A diamond blade known for its smooth cuts in porcelain and stone tiles.

These tools are not only instrumental in achieving professional-grade cuts but also enhance safety and efficiency in tile installation projects. For more detailed cutting guides and tool selections, explore how to cut tile effectively with various tools.

Types of Diamond Tile Cutters

Manual Diamond Tile Cutters

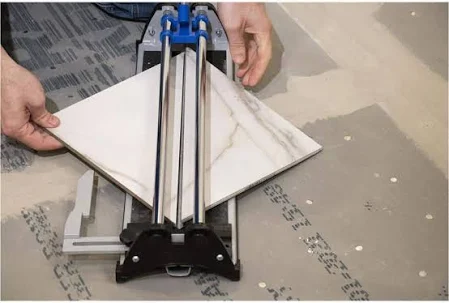

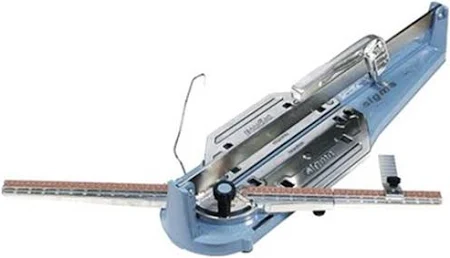

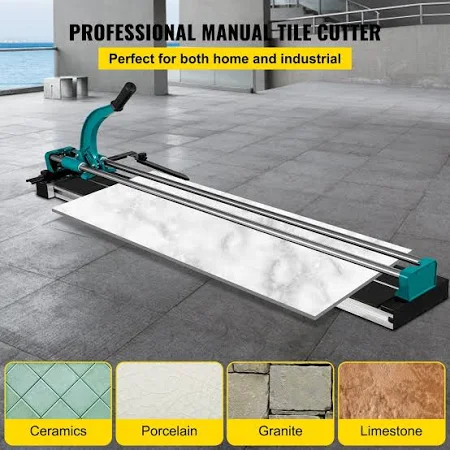

Diamond Tile Cutter tools are indispensable for both amateur DIY enthusiasts and professional tilers, providing an essential means for accurate and clean tile cutting. Among these tools, manual diamond tile cutters stand out for their simplicity, cost-effectiveness, and precision in handling various tile materials including ceramic, porcelain, and stone.

Characteristics of Manual Diamond Tile Cutters: Manual diamond tile cutters operate without electricity, relying on human force to score and snap tiles. This method is not only quieter but also allows for greater control over each cut. These cutters typically feature a rigid base, a cutting wheel composed of a diamond blade, and a lever to apply pressure.

Advantages in Bullet Points:

- Cost-Efficient: Less expensive than their electric counterparts, making them accessible for occasional or home projects.

- Portability: Lightweight and easy to transport, ideal for jobs where electricity is not readily available.

- Low Maintenance: With fewer moving parts, manual tile cutters are easy to maintain.

Popular Products:

- Sigma Tile Cutter 24 Inch: Renowned for its durability and precision, suitable for cutting larger tiles up to 24 inches.

- Brutus Tile Cutter: Known for its robust construction and ability to handle tough materials like porcelain and stone tiles.

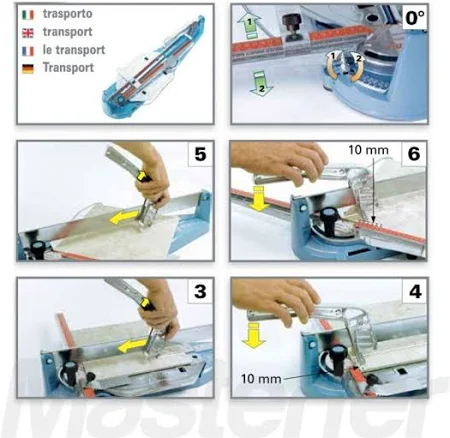

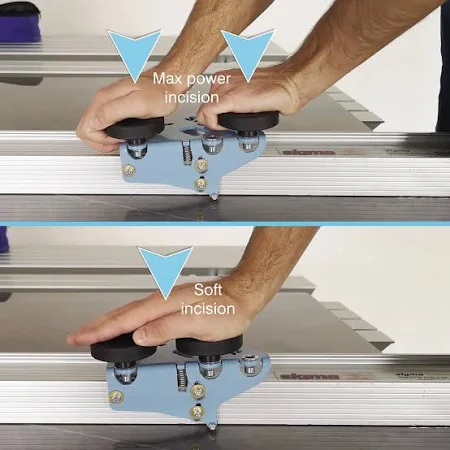

How Manual Diamond Tile Cutters Work:

- Positioning the Tile: The tile is placed on the cutter’s base and adjusted to ensure the cut line aligns with the cutting wheel.

- Scoring the Tile: The diamond cutting blade is pressed down and drawn across the surface of the tile to score it.

- Snapping the Tile: The lever is then used to apply pressure along the score line, cleanly breaking the tile along the desired cut.

Table: Comparison of Manual vs. Electric Tile Cutters

| Feature | Manual Tile Cutter | Electric Tile Cutter |

|---|---|---|

| Cutting Speed | Slower, dependent on user skill | Faster, consistent cuts |

| Precision | High, with skilled operation | High, enhanced by stable mechanisms |

| Noise Level | Low, suitable for indoor use without disturbance | Higher, may require noise mitigation |

| Portability | Excellent, no power requirement | Good, but requires power source |

| Best Used For | Smaller projects, intricate designs | Large volume projects, repetitive cuts |

| Cost | Lower initial investment | Higher due to complex components |

Choosing the Right Manual Diamond Tile Cutter

When selecting a manual diamond tile cutter, consider the types of tiles you’ll be cutting most frequently. For ceramic tiles, a standard manual tile cutter is typically sufficient. For tougher materials like porcelain or marble, opt for a more robust model like the Sigma Tile Cutter 24 Inch.

When to Use a Manual Tile Cutter:

- Small to Medium Projects: Ideal for bathrooms, kitchens, or any area with detailed tile work.

- Precision Cuts: When you need control over every cut, particularly for intricate designs and custom tile shapes.

- On-site Adjustments: Perfect for making quick cuts on the job site without the need for bulky equipment.

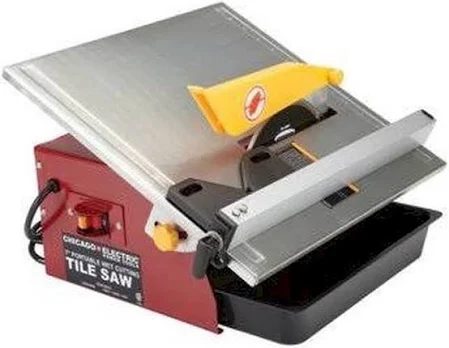

Electric Diamond Tile Cutters

Overview of Electric Diamond Tile Cutters

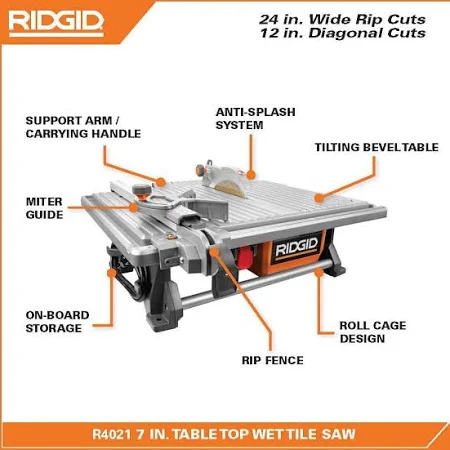

Diamond Tile Cutter technology has revolutionized the construction and home renovation industries, particularly through the development of electric tile cutters. These powerful tools are designed for efficiency and precision, utilizing diamond-infused blades to handle even the most challenging tile materials like porcelain and granite with ease.

Characteristics of Electric Diamond Tile Cutters: Electric diamond tile cutters are distinguished by their use of electricity to power a high-speed motor that drives a diamond blade. This setup allows for rapid, continuous cutting with minimal physical effort from the operator.

Advantages in Bullet Points:

- Efficiency: High cutting speeds reduce project time significantly.

- Precision: Ensures uniformly cut tiles, essential for professional-quality installations.

- Versatility: Capable of performing straight, diagonal, and curved cuts on a variety of tile types.

Popular Models:

- DeWalt D24000S Wet Tile Saw: Offers a robust design with a plunge feature that allows for quick plunge cuts for electrical outlets and A/C registers.

- MK Diamond MK-370EXP: Known for its lightweight design and powerful cutting capabilities, ideal for handling intricate and detailed cutting tasks.

Types of Electric Diamond Tile Cutters

Electric diamond tile cutters come in various types to suit different cutting needs:

- Wet Tile Saws: Use water to cool the diamond blade, minimizing dust and extending blade life. Perfect for large projects that require extensive cutting.

- Handheld Tile Saws: Offer more flexibility and are ideal for making quick cuts on already-installed tiles or for use in tight spaces.

- Tabletop Tile Saws: Combine power with stability, allowing for precise cuts on larger tiles.

Table: Features of Different Electric Tile Cutter Types

| Type | Best For | Pros | Cons |

|---|---|---|---|

| Wet Tile Saws | Large projects, thick materials | High precision, water-cooled | Bulky, requires setup and maintenance |

| Handheld Saws | Quick cuts, small corrections | Portable, easy to maneuver | Less stability, limited cut precision |

| Tabletop Saws | Precision cutting, volume cutting | Stable, supports larger tiles | Less portable, requires space |

Selecting the Right Electric Diamond Tile Cutter

Choosing the right electric diamond tile cutter depends on several factors:

- Tile Material: Harder materials like porcelain or granite may require a more powerful wet saw.

- Project Size: Larger projects benefit from stationary saws with larger blades and cutting surfaces.

- Precision Requirements: For projects requiring high precision, such as tiling a shower or intricate patterns, a tabletop saw is preferable.

Top Recommended Electric Diamond Tile Cutters

For those in the market for a reliable cutter, consider the following:

- MK Tile Saw: Renowned for its durability and capable of handling large format tiles with precision.

- Ryobi Tile Cutter: A versatile option that balances power and affordability, suitable for both DIY and professional use.

How to Maximize Efficiency with Electric Tile Cutters

- Regular Maintenance: Keep the blade sharp and the machine clean.

- Proper Blade Selection: Use the correct blade type for the material being cut to prevent chipping and extend the life of the blade.

- Safety First: Always follow manufacturer instructions and wear appropriate safety gear.

For detailed cutting techniques or specific project guides, check out resources like How to Tile a Shower and How to Cut Tile, which provide expert advice and step-by-step instructions.

Wet Tile Cutters vs Dry Tile Cutters

When selecting the ideal Diamond Tile Cutter for your project, understanding the differences between wet and dry tile cutters is crucial. Each type offers unique advantages and is suited for different materials and environments.

Wet Tile Cutters

Wet tile cutters utilize water to cool the diamond blade during the cutting process. This method not only helps in reducing dust and debris but also extends the lifespan of the blade by preventing overheating.

Key Features:

- Water Cooling System: Prevents blade overheating and minimizes dust.

- Cleaner Cuts: Produces smooth, precise cuts, reducing tile breakage.

- Ideal for Large Projects: Especially effective for cutting large quantities of tile or hard materials like porcelain and stone.

Popular Products:

- MK Diamond MK-101: Known for its durability and ability to handle large tiles with precision.

- DeWalt D24000S Wet Tile Saw: Offers a plunge feature and is highly recommended for its portability and ease of use.

Dry Tile Cutters

Dry tile cutters, on the other hand, do not use water. They are typically simpler, more portable, and better suited for quick jobs or environments where water use is impractical.

Key Features:

- No Water Required: Makes it more suitable for quick repairs or where water is not readily available.

- Portability: Generally lighter and easier to transport than wet cutters.

- Dust Management: Although they produce more dust, modern dry cutters often come with attachments to connect to dust extraction systems.

Popular Products:

- Ryobi Cordless Tile Cutter: Offers mobility without the hassle of cords, ideal for small indoor jobs.

- Sigma 3D2 Series Tile Cutter: Known for precision in dry cutting environments.

Table: Comparison of Wet and Dry Tile Cutters

| Feature | Wet Tile Cutter | Dry Tile Cutter |

|---|---|---|

| Dust Production | Low (water suppresses dust) | High (unless connected to a dust extractor) |

| Cutting Precision | High (water cools the blade for smoother cuts) | Moderate (precision depends on blade type and material) |

| Maintenance | Requires cleaning and water management | Minimal maintenance required |

| Usage Environment | Best for indoor or controlled environments | Versatile, suitable for both indoor and outdoor use |

| Types of Tiles | Ideal for porcelain, ceramic, and dense materials | Best for ceramic and light-duty cutting |

Choosing Between Wet and Dry Tile Cutters

The decision between a wet and a dry tile cutter should be based on the specific needs of your project:

- Material Type: Dense materials like porcelain and stone are best cut with a wet saw to prevent chipping.

- Project Size: Large projects or commercial jobs may benefit from the efficiency of a wet saw.

- Work Environment: For indoor environments or places where dust is a concern, wet saws are preferable.

Circular Saws with Diamond Blades

Introduction to Circular Saws with Diamond Blades

When it comes to precision and versatility in cutting tiles, a Diamond Tile Cutter equipped with a circular saw and a diamond blade is an indispensable tool. These setups are particularly effective for projects requiring quick, clean cuts across various tile materials, including porcelain, ceramic, and stone.

Key Features of Circular Saws with Diamond Blades

Circular saws with diamond blades combine the mobility of a handheld tool with the cutting prowess of diamond technology. This combination allows for both straight and curved cuts, making it an excellent choice for both DIY and professional projects.

Advantages in Bullet Points:

- Precision Cutting: Ensures straight, clean cuts with minimal chipping.

- Versatility: Suitable for a variety of materials, including dense and delicate tiles.

- Portability: Easily transportable, perfect for on-site cutting tasks.

Popular Products:

- DeWalt DCS690X2 FlexVolt 60V Max: Known for its cordless design and power, ideal for cutting tough materials on the go.

- Makita 4100KB Dry Masonry Saw: Offers dust extraction while providing precise cuts with its diamond blade.

Types of Diamond Blades for Circular Saws

The effectiveness of a circular saw largely depends on the type of diamond blade used. There are several types designed for different cutting scenarios:

- Continuous Rim Blades: Provide smooth, precise cuts, perfect for cutting delicate tiles and achieving a clean finish.

- Segmented Rim Blades: Feature cut-outs—segments—that help keep the blade cool during cutting, suitable for materials like stone and concrete.

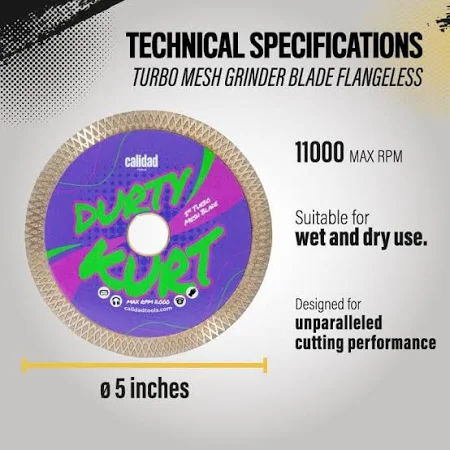

- Turbo Rim Blades: Combine the qualities of both continuous and segmented rims, offering faster cutting speeds and suitable for a broader range of materials.

Table: Comparison of Blade Types

| Blade Type | Best for Materials | Cut Type | Speed | Finish |

|---|---|---|---|---|

| Continuous Rim | Porcelain, ceramic | Smooth and clean | Slower | High-quality |

| Segmented Rim | Stone, concrete | Rough | Faster | Coarse |

| Turbo Rim | General, versatile | Smooth but quick | Fast | Good |

Choosing the Right Circular Saw with a Diamond Blade

Selecting the right circular saw with a diamond blade involves considering several factors:

- Material Type: Determine what types of tiles you will be cutting most frequently.

- Cutting Environment: Consider whether you will be cutting in a wet or dry environment. Wet cutting reduces dust but requires water accessibility.

- Blade Compatibility: Ensure the diamond blade is compatible with the saw for optimal performance and safety.

Enhancing Cutting Performance

To maximize the efficiency and longevity of your circular saw and diamond blade:

- Regular Maintenance: Regularly check and replace worn-out blades to maintain cutting precision.

- Proper Usage: Follow the manufacturer’s guidelines for use to prevent overheating and ensure clean cuts.

- Safety Measures: Always wear appropriate safety gear, including eye protection and gloves.

Top Recommended Circular Saws with Diamond Blades

For those seeking high-quality equipment, consider the following:

- Makita 4100KB: Provides exceptional control and durability for cutting a variety of tiles.

- DeWalt DCS690X2: Offers cordless convenience without sacrificing power, perfect for both indoor and outdoor projects.

Tile Grinders and Diamond Cutting Discs

Introduction to Tile Grinders and Diamond Cutting Discs

When precision and versatility are paramount, Diamond Tile Cutters equipped with grinders and diamond cutting discs provide a powerful solution for shaping and finishing tiles. Ideal for both renovations and new installations, these tools allow for detailed work on a variety of tile materials, from ceramic to porcelain and stone.

Key Features of Tile Grinders

Tile grinders are handheld tools that use diamond cutting discs to grind, shape, and smooth the edges of tiles. They are essential for making precise adjustments that larger saws cannot achieve.

Advantages in Bullet Points:

- Precision: Allows for fine adjustments and shaping of tile edges.

- Versatility: Can be used on a wide range of materials, including the hardest tiles.

- Portability: Compact and easy to maneuver, making them ideal for onsite work.

Popular Products:

- Bosch GWS 7-115 Professional Angle Grinder: Known for its reliability and ease of use, perfect for both DIY enthusiasts and professionals.

- Makita 9557PBX1 Angle Grinder: Offers a powerful motor in a compact body, enhancing control and comfort during extended use.

Understanding Diamond Cutting Discs

Diamond cutting discs are the cutting agents in tile grinders. These discs come in various sizes and grits, designed to suit different materials and cutting requirements.

Types of Diamond Cutting Discs:

- Continuous Rim Discs: Provide smooth, precise cuts, ideal for cutting delicate tiles without chipping.

- Segmented Rim Discs: Offer faster cutting through harder materials, with segment gaps that help keep the disc cool.

- Turbo Rim Discs: Combine the benefits of continuous and segmented rims for faster cutting without sacrificing finish quality.

Table: Features and Applications of Diamond Cutting Discs

| Disc Type | Best for Materials | Cut Type | Speed | Finish |

|---|---|---|---|---|

| Continuous Rim | Ceramic, glass | Precise and clean | Moderate | High-quality |

| Segmented Rim | Concrete, stone | Fast | Fast | Rougher |

| Turbo Rim | General, mixed | Fast and clean | High | Good |

Choosing the Right Tile Grinder and Diamond Disc

Selecting the correct tile grinder and diamond disc requires understanding the specific needs of your project:

- Material Type: Harder materials like porcelain and granite may need more robust discs like segmented or turbo rims.

- Cutting Purpose: Decide if you need the tool for intricate shaping (continuous rim) or rapid material removal (segmented rim).

- Grinder Compatibility: Ensure the disc fits your grinder model for optimal performance and safety.

Best Practices for Using Tile Grinders

To achieve the best results and maintain safety while using tile grinders and diamond discs:

- Proper Installation: Always ensure the disc is securely attached to the grinder.

- Protective Gear: Use gloves, eye protection, and ear protection to safeguard against potential hazards.

- Dust Management: Consider using a grinder with a dust extraction system to maintain a clean work environment.

Recommended Products

For those looking for top-quality tile grinders and discs, consider the following:

- Makita 9557PBX1 Angle Grinder: Perfect for detailed tile modifications and prolonged use.

- Bosch Diamond Cutting Disc: Offers durability and precision for a variety of tile materials.

Understanding Tile Cutting Blades

Introduction to Tile Cutting Blades

In the world of Diamond Tile Cutters, the blade is a critical component that determines the efficiency, precision, and type of cut achievable on various tile materials. Whether you are a professional installer or a DIY enthusiast, understanding the different types of tile cutting blades is essential for selecting the right tool for your project.

Types of Tile Blades

Tile blades are specifically designed to address different cutting needs and tile materials. Each blade type offers unique characteristics that optimize performance for specific cutting tasks.

Tile Cutting Blades

- General Use: Ideal for basic, straight cuts on ceramic and porcelain tiles.

- Features: These blades usually have a continuous rim coated with diamond particles to ensure a clean cut.

- Popular Products: The DeWalt XP4 for its thin kerf design which reduces chipping.

Tile Saw Blades

- Specific Use: Designed for use in tile saws, these blades can handle larger and denser tiles.

- Features: Wet saw blades are typically used for these applications to keep the blade cool and minimize dust.

- Recommended Product: The MK Diamond MK-215GL provides a glass tile blade specifically made for chip-free cuts on delicate tiles.

Diamond Tile Blades

- Precision Cutting: Best for materials that require precision cuts, such as glass or premium stone.

- Features: These blades can come in different rim types, including turbo rims, which combine speed and smooth cutting ability.

- Top Choice: The Bosch DB743S offers a continuous rim blade that delivers clean cuts with minimal chipping.

Tile Cutter Blades

- Versatile Use: These blades are suited for manual tile cutters and motorized tile cutters for straight and diagonal cuts.

- Features: They are designed to score the tile surface before breaking, ensuring a precise line.

- Preferred Product: The Sigma 2B3 Series Blade is renowned for its durability and precision in manual tile cutting.

Choosing the Right Blade for Your Project

Selecting the right tile cutting blade involves considering several factors:

- Material Type: Harder materials like porcelain and granite will require a different blade type than softer materials like ceramic.

- Cut Quality: Decide whether you need a chip-free finish or if a rough cut is acceptable based on the installation area.

- Wet or Dry Cutting: Wet blades require a water source but provide better cuts and reduced dust; dry blades offer convenience and portability.

Table: Blade Selection Guide

| Blade Type | Material Compatibility | Cut Finish | Water Requirement |

|---|---|---|---|

| Continuous Rim | Ceramic, Porcelain | Smooth, No chips | Wet |

| Segmented Rim | Stone, Concrete | Rough, Fast | Dry/Wet |

| Turbo Rim | Multi-material | Smooth, Fast | Dry/Wet |

Maintenance and Safety Tips

To ensure the longevity of your diamond tile blades and safe operation:

- Regular Checks: Inspect blades for wear and tear before each use.

- Proper Installation: Make sure blades are securely fastened and correctly aligned.

- Safety Gear: Always wear appropriate safety equipment, including goggles and gloves.

Wet Saw Blades vs Dry Blades

Overview of Wet Saw Blades and Dry Blades

When utilizing a Diamond Tile Cutter, choosing between wet saw blades and dry blades is crucial depending on your project’s needs. These blades differ fundamentally in their use, cutting capabilities, and the materials they are best suited for.

Wet Saw Blades

Wet saw blades are designed for use with a water coolant system, which reduces dust and heat during the cutting process. This feature is particularly important when making cuts on materials that are prone to cracking or chipping.

Key Features of Wet Saw Blades:

- Water Cooling: Reduces friction and heat, preventing damage to the blade and the material.

- Cleaner Cuts: Produces smooth, precise cuts with minimal dust.

- Material Suitability: Ideal for cutting dense materials like porcelain, granite, and other natural stones.

Popular Products:

- MK Diamond MK-215GL: Optimized for cutting glass tiles with minimal chipping.

- Bosch DB743S Continuous Rim Wet Saw Blade: Known for its clean cuts in ceramic and stone tiles.

Dry Blades

Dry blades are designed to operate without water, making them suitable for quick jobs where setup and cleanup of a water system are inconvenient. They are typically used for less precise cuts or where a little dust is not a concern.

Key Features of Dry Blades:

- No Water Needed: Allows for quick setup and operation.

- Portability and Convenience: Ideal for jobsites without access to water.

- Material Suitability: Best for dry cutting concrete, stone, and bricks.

Top Choices:

- DeWalt DW4725 High-Performance Dry Cutting Blade: Fast and durable, designed for a range of building materials.

- Makita A-94552 Diamond Blade: Provides excellent performance in dry conditions on a variety of hard materials.

Comparing Wet and Dry Blades

Understanding the differences between these two types of blades can help you choose the right one for your project:

Table: Wet vs. Dry Blades Comparison

| Feature | Wet Saw Blades | Dry Blades |

|---|---|---|

| Cutting Method | Use water to cool and lubricate during cutting | Cut dry, often producing more dust and noise |

| Cut Quality | Cleaner and smoother cuts | Faster but potentially less precise cuts |

| Material Suitability | Ideal for porcelain, glass, and dense stones | Suitable for concrete, bricks, and pavers |

| Setup Required | Requires setup for water source | No setup required; more flexible and portable |

Choosing the Right Blade for Your Needs

- Consider the Material: Harder materials like porcelain and glass typically require a wet blade for clean cuts without chipping.

- Assess the Job Requirements: For quick, small jobs or where water use is impractical, dry blades are preferable.

- Dust Management: In environments where dust is a concern, such as indoor settings, wet blades help minimize airborne particles.

Safety and Maintenance Tips

- For Wet Saw Blades: Always ensure adequate water flow to prevent overheating and blade damage.

- For Dry Blades: Check for excessive wear and ensure blades are sharp to reduce dust and potential kickback.

Choosing the Right Blade for Cutting Tiles

Selecting the Perfect Tile Cutting Blade

When using a Diamond Tile Cutter, the selection of the right blade is crucial to achieving desired results. Different types of tiles and cutting requirements demand specific blade characteristics. The correct blade not only ensures efficiency but also extends the life of both the blade and the tile cutter.

Key Factors to Consider

- Tile Material: The hardness and texture of the tile material are decisive in selecting the blade. Harder materials like porcelain or granite require a diamond blade with a softer bond to cut effectively.

- Type of Cut: Whether you need a clean cut for visible surfaces or a quick cut for tiles that will be hidden under trim plays a role in blade selection.

- Wet or Dry Cutting: Choose between wet and dry blades based on the cutting environment and equipment.

Top Blade Recommendations:

- For Porcelain Tiles: Use a diamond blade specifically designed for porcelain to avoid chipping, such as the MK Diamond MK-215GL.

- For Ceramic Tiles: A continuous rim blade provides smooth cuts, ideal for materials like ceramic.

Types of Blades and Their Uses

Understanding the different types of blades will help you make an informed decision:

Continuous Rim Blades

- Best For: Smooth, precise cuts on ceramic and glass tiles.

- Feature: A continuous rim that helps keep the cut edge clean.

- Product Pick: The Bosch DB743S Continuous Rim Wet Saw Blade.

Segmented Rim Blades

- Best For: Cutting through tough materials like stone and concrete.

- Feature: Segments that help remove debris and cool the blade, making it suitable for dry cutting.

- Product Pick: The DeWalt DW4725 High-Performance Dry Cutting Blade.

Turbo Rim Blades

- Best For: Faster cuts with a decent finish on a variety of materials.

- Feature: Turbo rims combine the speed of segmented rims with the smoothness of continuous rims.

- Product Pick: The Makita A-94552 Diamond Blade, which offers both speed and clean cuts.

Choosing the Right Blade for Specific Projects

- For Large Format Tiles: Opt for a larger blade that can handle the length of the cut, like the 48 Inch Tile Cutter blades available at specialized retailers.

- For Intricate Shapes: A smaller, more precise blade like the Ryobi Tile Cutter Blade is suitable for detailed work.

Maintenance and Care of Tile Cutting Blades

- Regular Cleaning: Keep your blades clean from debris to ensure longevity and performance.

- Proper Installation: Ensure the blade is installed according to the manufacturer’s guidelines to prevent accidents and maintain efficiency.

- Blade Sharpness: Regularly check the sharpness of the blade. A dull blade can result in uneven cuts and potential damage to the tile.

Table: Blade Selection Guide

| Material Type | Recommended Blade Type | Recommended Product |

|---|---|---|

| Porcelain | Continuous Rim | Best Tile Cutter For Porcelain |

| Ceramic | Continuous Rim | Bosch DB743S Continuous Rim Wet Saw Blade |

| Stone | Segmented Rim | DeWalt DW4725 High-Performance Dry Cutting Blade |

| Multi-material | Turbo Rim | Makita A-94552 Diamond Blade |

Top Tools and Accessories for Tile Cutting

Essential Tools for Precision and Efficiency

Selecting the right tools and accessories is essential for achieving precision cuts and efficient workflows in tile installation. Whether you are dealing with porcelain, ceramic, or natural stone, having the right Diamond Tile Cutter and related accessories can make a significant difference.

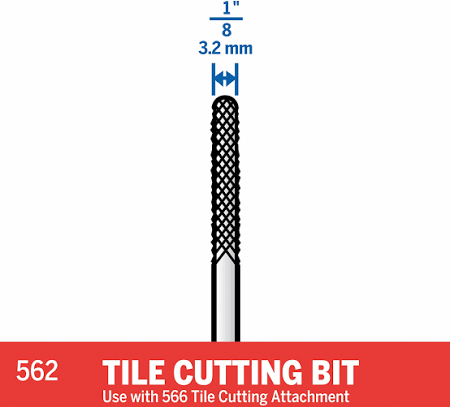

Tile Cutting Disc for Grinders

- Purpose: Used for making quick, precise cuts and adjustments on a range of tile types.

- Key Product: The Makita A-94552 Diamond Blade, which offers durability and precision for both wet and dry use.

- Ideal For: Adjusting tile sizes on-the-fly or shaping tiles to fit around obstacles.

Tile Grinder Blades

- Usage: Specifically designed to handle the rigors of cutting through tough tile materials with grinders.

- Recommended Blade: The Bosch DB763 Direct Drive Diamond Blade provides clean, consistent cuts with a reduced risk of chipping.

- Applications: Perfect for jobs requiring intricate detail work or small adjustments.

Tile Blade for Circular Saw

- Function: Enables circular saws to cut through tile with precision.

- Top Choice: The DeWalt DW4764 Premium XP4 Tile Blade, known for its long life and ability to cut through tile cleanly and efficiently.

- Advantages: Offers the flexibility to handle larger tiles and bulk cutting tasks.

Diamond Cutter for Tiles

- Features: Diamond cutters provide the highest level of precision in cutting tiles, utilizing diamond grit embedded in the cutter wheel.

- Product Highlight: The RIDGID 10-inch Diamond Edge Tile Circular Saw Blade excels in performance and durability.

- Suitability: Best for projects that require exact cuts without damage to the material.

Miter Saw Tile Blades

- Application: Designed for use in miter saws to ensure accurate angle cuts for tile installation.

- Recommended Product: The QEP 6-7006GLQ 7-Inch Continuous Rim Glass Tile Diamond Blade, which is optimized for cutting glass tile but also excellent for porcelain and ceramic.

- Benefits: Enables precise angular cuts, which are essential for complex tile layouts and corners.

Choosing the Right Tools

When selecting tools and blades for tile cutting, consider the following factors:

- Material Hardness: Harder materials like porcelain and granite require blades with a finer grit.

- Cut Type: Decide whether you need a smooth, decorative cut or a standard cut for utility purposes.

- Tool Compatibility: Ensure that the blades and tools are compatible with the machines you plan to use them with.

Comparison Table: Tile Cutting Tools and Their Best Uses

| Tool Type | Best for Material | Best Use Case | Recommended Product |

|---|---|---|---|

| Tile Cutting Disc | All tile types | Shaping and quick trims | Makita A-94552 Diamond Blade |

| Tile Grinder Blade | Tough materials | Detailed adjustments, small cuts | Bosch DB763 Direct Drive Diamond Blade |

| Tile Blade for Circular Saw | Large tile sheets | Bulk cutting, large format tiles | DeWalt DW4764 Premium XP4 Tile Blade |

| Diamond Cutter | High-end porcelain, glass | Precision cuts | RIDGID 10-inch Diamond Edge Circular Saw Blade |

| Miter Saw Tile Blade | Glass, ceramic | Angular cuts, decorative elements | QEP 6-7006GLQ Glass Tile Diamond Blade |

Best Diamond Blades for Specific Applications: Porcelain Tile Blades

Introduction to Porcelain Tile Blades

In the realm of Diamond Tile Cutters, selecting the ideal blade for cutting porcelain tiles is critical due to the material’s hardness and potential for chipping. Porcelain tile blades are specially designed to handle the rigors of cutting through one of the toughest materials in the tiling industry, ensuring smooth, clean cuts with minimal damage.

Choosing the Right Porcelain Tile Blade

Porcelain tiles require diamond blades that can deliver precision without compromising the tile’s integrity. These blades are typically made with a finer diamond grit and a harder bond to withstand the tough characteristics of porcelain.

Key Features to Consider:

- Blade Type: Continuous rim blades are preferred for their ability to make clean, chip-free cuts.

- Diamond Grit: A finer grit allows for smoother cuts and helps reduce the chance of chipping.

- Wet vs. Dry Cutting: Wet cutting is generally recommended for porcelain to keep the blade cool and minimize dust.

Top Blade Recommendations:

- MK Diamond MK-215GL: Specifically designed for cutting glass and porcelain, providing smooth cuts without chipping.

- Bosch DB869 Continuous Rim Diamond Blade: Known for its long life and ability to cut through porcelain tiles cleanly.

Why Choose These Blades?

MK Diamond MK-215GL

- Design: Thin-rim design enhances cutting quality and speed while reducing material waste.

- Application: Ideal for cutting porcelain tiles that are prone to chipping when using standard blades.

Bosher DB869 Continuous Rim Diamond Blade

- Durability: Offers extended blade life due to its high-quality diamond matrix.

- Efficiency: Provides fast, reliable cuts, making it suitable for both professional contractors and DIY enthusiasts.

Usage Tips for Porcelain Tile Blades

- Proper Installation: Ensure that the blade is correctly installed and aligned on your cutting tool.

- Optimal Speed: Use the recommended RPM settings to avoid overheating the blade.

- Regular Water Flow: When wet cutting, maintain a steady flow of water to enhance blade performance and longevity.

Maintenance and Care

- Blade Cleaning: Keep the blade clean from tile residue to maintain cutting efficiency.

- Inspection: Regularly inspect the blade for wear and replace it when the diamond rim shows signs of smoothness.

- Storage: Store the blade in a dry, safe place to prevent corrosion and wear.

Best Diamond Blades for Specific Applications: Cutting Marble and Granite, and Porcelain Tiles

Blades for Cutting Marble and Granite

When working with Diamond Tile Cutters to slice through marble and granite, the choice of blade can dramatically affect the quality of the cut and the overall ease of the job. These materials require blades that can deliver a combination of sharp precision and durability to handle their dense composition.

Key Considerations for Marble and Granite Blades:

- Blade Type: Segmented rim blades are often preferred for their ability to cut through dense materials quickly and efficiently.

- Diamond Grit and Bond: Harder bonds and high-quality diamonds are essential for cutting through these tough materials without rapid wear.

- Wet Cutting Preference: Wet blades are typically recommended to help prevent overheating and reduce dust.

Top Blade Recommendations:

- DeWalt DW4765 4.5-Inch Premium Diamond Blade: Known for its high performance on granite and hard materials.

- Bosch DB1041S 10-Inch Segmented Rim Diamond Blade: Offers durability and precision for frequent users cutting through granite and marble.

Wet Saw Blades for Porcelain Tile

Porcelain tiles, known for their hardness and density, necessitate blades that can deliver clean, chip-free cuts. Using the right blade in a wet saw setup not only improves the cutting experience but also extends the life of the blade.

Essential Features for Porcelain Tile Blades:

- Blade Type: Continuous rim blades are ideal for achieving a smooth finish.

- Fine Diamond Grit: Ensures smoother cuts and helps maintain the integrity of the porcelain.

- Wet Cutting Necessity: Keeps the blade cool and minimizes dust for cleaner operations.

Leading Blade Choices:

- MK Diamond MK-225 Hot Dog Wet Cutting Diamond Blade: Renowned for its thin kerf and precision cutting capabilities on porcelain.

- QEP 6-1008BW 10-Inch Black Widow Micro-Segmented Rim Diamond Blade: Specifically designed for cutting porcelain tiles, known for reducing chipping and ensuring a clean finish.

Usage and Maintenance Tips:

- Proper Installation: Always ensure the blade is securely installed on your tile saw or grinder to prevent mishaps.

- Optimal Speed Settings: Follow manufacturer guidelines for blade speed to maximize efficiency and protect the blade’s lifespan.

- Regular Water Flow: For wet saw applications, maintaining a consistent water flow is critical to prevent blade overheating and reduce wear.

Choosing the Right Blade:

- Match the Blade to Material Hardness: Use blades designed specifically for the hardness of the material—marble and granite blades are not interchangeable with porcelain blades without compromises in performance.

- Check Compatibility: Ensure that the blade diameter and arbor size fit your saw or grinder perfectly to avoid operational issues.

Comparison Table for Quick Selection:

| Material Type | Recommended Blade Type | Key Feature | Product Recommendation |

|---|---|---|---|

| Marble | Segmented Rim | Fast cutting, durable | Bosch DB1041S 10-Inch Segmented Rim Diamond Blade |

| Granite | Segmented Rim | Hard bond, durable | DeWalt DW4765 4.5-Inch Premium Diamond Blade |

| Porcelain Tile | Continuous Rim | Smooth finish, minimal chipping | MK Diamond MK-225 Hot Dog Wet Cutting Blade |

Best Tile Blade for Grinders and Circular Saws

Optimizing Your Cutting Tools with the Right Blades

When it comes to using Diamond Tile Cutters with grinders and circular saws, the blade choice can significantly influence the outcome and efficiency of your project. These tools are vital for those who require precision and speed in their tile cutting tasks, particularly when working with tough materials like porcelain, ceramic, or even natural stone.

Choosing Blades for Grinders

Grinders are typically used for smaller, more precise cuts or when shaping tile corners and curves. The blade you choose must be capable of handling detailed work without causing damage to the tiles.

Key Features to Consider:

- Blade Type: Smaller diamond cutting discs are preferred for grinders due to their ability to make detailed cuts.

- Material Compatibility: Ensure the blade is suitable for the tile material to prevent chipping or cracking.

- Recommended Product: The Makita A-94605 Diamond Blade is highly effective for detailed grinding work on ceramic and stone tiles.

Selecting Blades for Circular Saws

Circular saws are chosen for their ability to make straight, long cuts faster. They are ideal for cutting large pieces of tile or handling bulk projects efficiently.

Essential Considerations:

- Blade Diameter: Larger blades allow for deeper and longer cuts, suitable for large format tiles.

- Diamond Grit: Choose a blade with a fine grit for smooth cuts, especially important for visible areas.

- Top Choice: The DeWalt DW4764 10-inch Diamond Blade offers a continuous rim that delivers precise, chip-free cuts on a variety of tile materials.

Best Practices for Using Diamond Blades in Grinders and Circular Saws

- Proper Installation: Ensure blades are securely attached to prevent slippage and potential accidents.

- Appropriate Speed: Utilize the correct speed settings for the material being cut to maximize blade life and cut quality.

- Safety Measures: Always wear safety goggles, gloves, and ear protection when operating power tools.

Maintenance Tips for Diamond Blades

- Regular Inspection: Check for wear and tear before and after each use to maintain optimal cutting performance.

- Cleaning: Remove any debris from the blade after use to keep it in good condition.

- Storage: Store blades in a dry and safe environment to prevent rust and damage.

Blade Recommendations for Specific Tile Types

- Porcelain Tiles: Use a continuous rim diamond blade like the Bosch DB869 for the best results on hard porcelain tiles.

- Ceramic Tiles: The QEP 6-7003Q 7-Inch Diamond Blade is excellent for achieving clean cuts on ceramic tiles.

- Natural Stone: For materials like marble or granite, the DeWalt DW4765 is recommended for its segmented rim that cuts through tough stone with ease.

Choosing the Right Diamond Tile Cutter

Introduction to Diamond Tile Cutters

Selecting the perfect Diamond Tile Cutter is crucial for professionals and DIY enthusiasts alike who seek precision and efficiency in their tiling projects. The right cutter can make a significant difference in the quality of your cuts, the speed of your work, and the longevity of your tools.

Factors to Consider When Choosing a Diamond Tile Cutter

To ensure you select the best diamond tile cutter for your needs, several key factors need to be considered:

1. Tile Material

- Porcelain, Ceramic, or Stone: The hardness of the material determines the type of diamond blade needed.

- Porcelain requires a harder, more durable blade for clean cuts.

- Ceramic can be cut with a less aggressive blade due to its softer composition.

- Stone, including marble and granite, needs a very tough blade, often with segmented rims for effective cutting.

2. Blade Type

- Continuous Rim Blades: Ideal for achieving clean and precise cuts on materials like porcelain and ceramic.

- Segmented Rim Blades: Best for harder materials such as granite or other natural stones, as they offer faster cutting with good cooling but rougher finishes.

- Turbo Blades: Combine the qualities of continuous and segmented rims, providing faster cuts without sacrificing too much finish quality.

3. Wet Cutting vs Dry Cutting

- Wet Cutting: Preferred for most tile materials as it keeps the blade cool, extends its life, and minimizes dust. Essential for materials like porcelain and natural stone.

- Dry Cutting: More convenient for quick jobs or outdoor cutting where water setup is impractical.

4. Blade Size and Compatibility

- Matching Blade to Tool: Ensure the blade size fits your cutter’s specifications—incorrect sizing can lead to inefficient cutting or damage to the blade and tool.

- Blade Arbor Size: The hole in the center of the blade must match the arbor size of your saw to ensure a secure fit.

Top Blade Recommendations and Their Best Uses

- For Porcelain: The MK Diamond MK-225 Hot Dog blade is renowned for wet cutting, providing smooth and chip-free cuts.

- For Ceramic: The QEP 6-1008BW Black Widow offers a continuous rim for precise cutting of ceramic tiles.

- For Stone: The DeWalt DW4765 segmented diamond blade excels in cutting through granite and other hard materials.

Making the Right Choice

When selecting your diamond tile cutter, consider:

- The nature of your projects: Frequency, material type, and precision requirements.

- Your work environment: Whether it supports wet cutting or necessitates dry cutting.

- Budget and blade availability: Invest in the best blade you can afford to avoid multiple purchases and ensure a high-quality finish.

Top 10 Best Diamond Tile Cutters and Blades

Introduction to Diamond Tile Cutters and Blades

Choosing the right Diamond Tile Cutter and blade can significantly impact the efficiency and quality of your tiling projects. With a range of materials like porcelain, ceramic, and stone, it’s vital to select tools that match the specific needs of your project for optimal cutting performance.

Product Reviews and Comparisons

Here, we will explore the top diamond tile cutters and blades, focusing on their applications, advantages, and ideal usage scenarios to help you make the best purchase decision.

1. Best Overall Tile Cutter: MK Diamond MK-101

- Features: A powerful high-torque motor and a built-in water pump for wet cutting.

- Best For: Versatile cutting of both porcelain and ceramic tiles.

- Why Choose: It offers precision and durability with a large cutting capacity.

2. Best Value Tile Cutter: SKIL 3550-02 Wet Tile Saw

- Features: HydroLock Water Containment System keeps water splash to a minimum.

- Best For: Home renovations and small to medium tiling projects.

- Why Choose: It’s affordable without compromising on essential features like a durable diamond-coated blade.

3. Best for Professionals: DeWalt D24000S Wet Tile Saw

- Features: A robust 1.5 HP motor capable of handling large format tiles.

- Best For: Heavy-duty use in professional settings.

- Why Choose: Precision cutting with a rail system that ensures accurate cuts every time.

4. Best Handheld Tile Cutter: Makita CC02R1 12V Max CXT

- Features: Compact design with water supply tank for wet cutting.

- Best For: Quick cuts and touch-ups on the go.

- Why Choose: Portable and easy to maneuver, perfect for intricate work on porcelain and ceramic tiles.

5. Best for Porcelain Tiles: Bosch DB743S 7-Inch Continuous Rim Diamond Blade

- Features: Diamond matrix for long life and precision cutting.

- Best For: Smooth and chip-free cuts on porcelain tiles.

- Why Choose: It balances cutting speed and finish quality superbly.

6. Best Multi-Material Cutter: QEP 10630Q Manual Tile Cutter

- Features: Dual chrome-plated rail bars and a linear ball bearing slide for smooth scoring.

- Best For: A variety of tile types, including ceramic and porcelain.

- Why Choose: Offers great versatility with a simple score and snap operation.

7. Best Budget-Friendly Blade: KING DIAMOND 7 in. Diamond Tile Circular Saw Blade

- Features: An economical option with a continuous rim for clean cuts.

- Best For: Budget-conscious DIYers needing effective cuts for ceramic and porcelain.

- Why Choose: It provides good performance at a low cost.

8. Best for Large Tiles: Rubi DC-250 1200 Wet Tile Saw

- Features: Plunge cut capabilities and a powerful motor designed for large tiles.

- Best For: Cutting large format tiles and slabs.

- Why Choose: Superior power and a cutting length of up to 47.2 inches.

9. Best Durability: Diamond Products Limited Wet Cutting Tile Blade

- Features: A high diamond concentration for longer blade life.

- Best For: Long-term use in cutting a variety of tile materials.

- Why Choose: It’s designed for longevity, reducing the frequency of blade replacements.

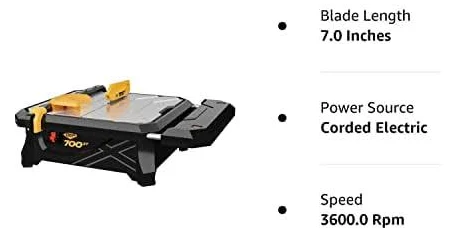

10. Best Compact Tile Saw: Ryobi 4 in. Tile Saw

- Features: Portable and lightweight with a powerful induction motor.

- Best For: Small projects and tight spaces.

- Why Choose: Its compact design does not sacrifice power or precision.

Choosing the Best Tile Saw Blade

When selecting a blade for your tile cutting needs, consider:

- Material Compatibility: Match the blade to the tile material for optimal cutting results.

- Cutting Style: Decide between wet and dry cutting based on your working environment and preferred method.

- Blade Size and Compatibility: Ensure the blade fits your cutter and is appropriate for the size of the tiles you are working with.

Best Tile Cutting Blade for Grinders

Choosing the Right Blade for Your Grinder

Selecting the perfect blade for your grinder is critical when working with various types of tiles. A Diamond Tile Cutter blade designed for grinders can make the difference between a mediocre result and a flawless finish. Let’s dive into the factors that make a blade ideal for use with grinders, ensuring precision and efficiency in your tile cutting tasks.

Factors to Consider When Selecting a Grinder Blade

Blade Type: The blade type must match the material of your tiles to prevent damage and achieve clean cuts.

- Continuous Rim Blades are best for tiles that require smooth, precise cuts without chipping, such as ceramic or glass tiles.

- Turbo Blades offer a good balance between speed and finish, suitable for natural stone tiles.

- Segmented Rim Blades are ideal for harder materials like granite or dense porcelain tiles, providing fast cuts with less concern about the finish.

Diameter and Thickness: Ensure the blade fits your grinder’s specifications. Smaller blades allow for intricate cuts in tighter spaces, while larger blades are suited for quicker, straight cuts.

Wet or Dry Cutting: Some blades are designed specifically for wet cutting to reduce dust and heat buildup, which is essential when working with materials like porcelain.

Recommended Blades for Grinders

- Bosch DB743S 7-Inch Continuous Rim Diamond Blade: Excellent for cutting porcelain and ceramic tiles, ensuring smooth cuts with minimal chipping.

- Makita A-94605 Diamond Blade: Known for its durability and efficiency in cutting granite and other hard materials.

- DEWALT DW4764 10-inch Diamond Blade: This blade is a top choice for professional-grade clean and smooth cuts on a variety of tile materials.

Using Diamond Blades with Your Grinder

- Proper Installation: Secure the blade correctly and ensure it’s aligned with the grinder’s guard for safe operation.

- Optimal Speed: Use the recommended speed for the specific blade and tile material to avoid overheating or damage to the tile.

- Safety Gear: Always wear appropriate safety equipment, including goggles, gloves, and ear protection, to safeguard against flying particles and noise.

Maintenance and Care

- Regular Checks: Inspect the blade for wear or damage before each use. Look for any segments that might be missing or any cracks that could affect performance.

- Cleaning: Keep the blade clean from any tile residue that could impact its cutting efficiency. A simple wipe-down post-use can prolong the blade’s life.

- Storage: Store the blade in a dry, safe place to prevent rust and ensure it remains sharp and ready for the next job.

Best Diamond Blade for Porcelain Tiles

When tackling a project that involves cutting porcelain tiles, choosing the right diamond blade is crucial to achieve precision and prevent tile damage. Porcelain tiles are especially hard and brittle, necessitating a Diamond Tile Cutter blade that can handle such material without chipping or cracking it. Here’s a guide to selecting the best diamond blade for cutting porcelain tiles, ensuring clean, professional results.

Key Features to Look for in a Porcelain Tile Blade

- Blade Type: Opt for a continuous rim blade, which provides the smoothest and cleanest cuts for delicate porcelain.

- Diamond Matrix: The quality of the diamonds in the blade affects both performance and longevity. High-quality diamonds will cut more efficiently and require less frequent replacements.

- Wet vs. Dry Cutting: Wet cutting blades are preferable for porcelain to reduce dust and heat, enhancing the cutting process and prolonging blade life.

Top Diamond Blades for Porcelain Tiles

- DEWALT XP4 10-inch Diamond Blade – Ideal for wet cutting, offers precise cuts with its fine diamond edge.

- Bosch DB743S 7-Inch Continuous Rim Diamond Blade – Known for its durability and clean cuts, perfect for both wet and dry applications.

- MK Diamond MK-225 Hot Dog 10-inch Wet Cutting Blade – Specifically designed for wet cutting porcelain tiles, offering minimal chipping and excellent performance.

Using Your Diamond Blade Effectively

- Proper Installation: Ensure that the blade is properly installed on your tile saw or grinder, with the right blade direction and securely tightened.

- Feed Rate: Adjust the feed rate according to the thickness of the porcelain. Slower feed rates are generally better for reducing breakage and achieving cleaner cuts.

- Water Flow: When using a wet saw, make sure there is consistent water flow over the blade to keep it cool and minimize dust.

Maintenance Tips

- Blade Cleaning: Keep the blade clean from any build-up to maintain sharpness and effectiveness.

- Regular Inspections: Check for any visible wear or damage before and after use to avoid any mid-project mishaps.

- Storage: Store the blade in a cool, dry place to prevent rust and wear when not in use.

Step-by-Step Guide to Cutting Tiles with a Circular Saw

Using a circular saw equipped with a diamond tile cutter blade can be an effective method for cutting various types of tiles, including ceramic, porcelain, and stone. This guide provides detailed steps and recommended products for successfully cutting tiles using a circular saw.

Preparing to Cut Tiles with a Circular Saw

- Select the Appropriate Blade: Use a diamond blade designed for tile cutting. For porcelain and hard tiles, opt for a continuous rim diamond blade to ensure smooth, clean cuts.

- Equip Your Saw: Ensure your circular saw is compatible with the blade size and type. Commonly used models include the DEWALT DWC860W Wet/Dry Hand-Held Tile Cutter and the Makita 4100NHX1 Masonry Saw, which are ideal for precision cutting.

- Safety First: Always wear safety goggles, gloves, and ear protection to guard against flying particles and noise.

Setting Up Your Workspace

- Secure Workspace: Ensure your cutting area is stable and well-lit. Use a workbench or a sturdy table to support the tile during cutting.

- Water Source for Wet Cutting: If using a wet-cut diamond blade, set up a water source to cool the blade and minimize dust. Tools like the SKIL 3540-02 7-inch Wet Tile Saw are equipped with a water reservoir.

- Mark the Tile: Use a pencil or chalk to mark where you need to cut the tile. Ensure the lines are clear and straight.

Cutting the Tile

- Align the Blade: Align the marked line with the blade. Adjust the blade depth to just below the tile thickness.

- Support the Tile: Secure the tile with clamps to prevent it from moving. If cutting a large piece, support the ends to prevent snapping.

- Begin Cutting: Turn on the saw and gently push the blade into the tile. Keep the saw steady and progress slowly along the marked line.

- Cooling and Dust Management: For dry cutting, periodically pause to allow the blade to cool. Use a shop vacuum to manage dust if not using a wet saw.

After Cutting

- Inspect the Cut: Check the tile for any chipping or imperfections. Smooth the edges with a sanding stone if necessary.

- Clean Up: Clean the saw blade and the work area. If using a wet saw, empty and clean the water reservoir to prevent sludge buildup.

Recommended Products

- Circular Saws: RYOBI 7 in. 4.8 Amp Tile Saw with Stand and Makita 4100NHX1 Masonry Saw.

- Diamond Blades: For smooth cuts, consider the Avanti Pro 7 in. Diamond Blade PD070S or the Diablo 4-1/2 in. Diamond Turbo Masonry Cut Off for tougher tiles.

- Safety Gear: Always ensure you have adequate personal protective equipment.

Cutting tiles with a circular saw can seem daunting, but with the right tools and techniques, it is entirely feasible to achieve professional results. Ensure to use the appropriate blade type, such as those found on the DEWALT DWC860W Wet/Dry Hand-Held Tile Cutter and maintain a steady hand and a well-prepared workspace to ensure precision in your tile cutting projects.

For further insights and to purchase suitable tile cutting tools, explore options like the RYOBI 7 in. Tabletop Tile Saw and other specialized equipment listed above to find the perfect tool for your tiling needs.

How to Use a Diamond Tile Cutter

Using a diamond tile cutter is crucial for achieving precise cuts on a variety of tile materials, such as porcelain, ceramic, and stone. This guide will explore the effective use of diamond tile cutters, from choosing the right blade to executing a cut.

Selecting the Right Diamond Tile Cutter

- Type of Blade: Depending on the material of the tile, choose between continuous rim blades (for clean cuts in ceramic and porcelain) or segmented rim blades (for faster cuts in harder materials like granite or marble).

- Blade Compatibility: Ensure the blade size fits your tile saw or angle grinder. Common sizes include 4.5-inch blades for hand-held grinders and 10-inch blades for table saws.

Preparation for Cutting

- Safety Gear: Always wear protective eyewear, gloves, and ear protection to safeguard against flying debris and loud noise.

- Setup Your Equipment: If using a wet saw like the DeWalt D24000R 10 in. Wet Tile Saw, ensure it has an adequate water supply to cool the blade and reduce dust.

- Mark the Tile: Clearly mark your cut line with a non-permanent marker for precision.

Cutting Process

- Align the Blade: Align the diamond blade with the mark on the tile. Adjust the blade height so it just exceeds the tile’s thickness.

- Perform the Cut: For a wet cut, start the saw and gently push the tile through the blade. For dry cuts, apply steady pressure and move the cutter along the mark in a smooth motion.

- Check the Cut: Inspect the tile for any chipping or uneven edges. Use a rubbing stone to smooth out any imperfections.

Post-Cutting

- Cleaning: After cutting, clean the tile of any debris and dust. Clean your diamond blade and inspect it for wear.

- Maintenance of the Cutter: Regularly check and replace the water in a wet saw to prevent residue build-up. For dry cutters, ensure the blade is free of tile fragments and dust.

Recommended Products and Their Uses

- Rubi TS-MAX Tile Cutter – Ideal for precise cutting of large ceramic tiles, available at Rubi Speed Plus Tile Cutter.

- Sigma 2B3 25 inch Tile Cutter – Perfect for professional cuts in ceramic and porcelain tiles, detailed here: Sigma Series 4 NEX Push Tile Cutter.

- QEP 700XT Wet Tile Saw – Suitable for both amateur and professional use, providing clean cuts with minimal chipping, see more at QEP 700XT Wet Tile Saw.

How to Cut Porcelain and Ceramic Tiles

Choosing the Right Tools and Blades

To achieve precise and clean cuts on both porcelain and ceramic tiles, using a diamond tile cutter equipped with the appropriate blade is critical:

- Diamond Blade for Porcelain Tile: Opt for a diamond blade specifically designed for porcelain tiles, like the Diamond Blade for Porcelain Tile, which offers a fine and clean cut with minimal chipping.

- Ceramic Tile Blades: For ceramic tiles, blades like the Ceramic Tile Cutter Blade can provide smooth and efficient cuts.

Step-by-Step Cutting Process

- Measure and Mark: Measure your tile and mark the cut line with a non-permanent marker.

- Setup the Cutter: Secure your tile on the cutter platform. For straight cuts, align the tile with the cutting guide.

- Cutting the Tile: Press the handle of the tile cutter to score a line on the surface. Apply even pressure along the score line to snap the tile cleanly.

How to Cut Tiles with a Grinder

Cutting tiles with a grinder requires a different approach and is ideal for making circular cuts or small cutouts:

- Select a Suitable Blade: Use a diamond blade like the Tile Grinder Blade for your angle grinder.

- Mark Your Cut: As before, mark your cut line on the tile.

- Secure the Tile: Ensure the tile is securely clamped down to prevent any movement.

- Cutting: Begin cutting along the marked line at a steady pace to prevent the blade from chipping the tile.

Safety Tips for Cutting Tiles

- Wear Protective Gear: Always wear safety goggles, gloves, and ear protection to shield yourself from tile shards and loud noise.

- Secure Your Workspace: Ensure that your tile is firmly clamped or placed on a non-slip surface to prevent accidents.

- Proper Handling of Tools: Always ensure that your cutting tools are in good working condition and that you handle them according to the manufacturer’s instructions.

Recommended Products

- DeWalt D24000R Wet Tile Saw: Perfect for large tiles and heavy-duty cutting, available at DeWalt D24000R 10 in. Wet Tile Saw.

- Rubi DC-250 Python Tile Saw: Ideal for precision cuts in both porcelain and ceramic tiles, detailed at Rubi DC-250 Python Tile Saw.

- QEP Torque Master Tile Saw: Suitable for smaller projects and finer work, see more at QEP Torque Master Tile Saw 22400Q.

Using the Wrong Diamond Blade for the Material

Selecting the appropriate diamond blade for cutting tile is critical to achieving clean cuts and maintaining the integrity of the material. Using the wrong blade can lead to numerous problems, such as inefficient cuts, excessive wear on the blade, and damage to the tile itself.

Understanding Diamond Blade Specifications

Before diving into the specifics, it’s important to understand that diamond blades are designed for different materials based on the hardness and abrasiveness of the material being cut. Here’s a breakdown of key factors to consider:

Blade Type

- Continuous Rim Blades: Provide the smoothest cut for delicate materials like ceramic and porcelain tiles. Recommended product: DeWalt D24000R 10 in. Wet Tile Saw equipped with a premium continuous rim blade.

- Segmented Rim Blades: Best for harder materials that require more aggressive cutting. Ideal for stone and marble tiles.

Materials

- Porcelain Tiles: Require a hard, continuous rim diamond blade for clean cuts. Use the Diamond Blade for Porcelain Tile.

- Ceramic Tiles: Less hard than porcelain, allowing for a softer blade that provides a smooth finish. Suitable blades can be found in products like the Rubi TS-MAX Tile Cutter.

Common Mistakes and Solutions

Using a Segmented Blade for Ceramic Tiles:

- Problem: Leads to chipping and uneven edges.

- Solution: Opt for a continuous rim blade designed for softer, less dense tiles.

- Product Suggestion: Sigma 2B3 25 inch Tile Cutter with a proper ceramic cutting blade.

Using a Dull Blade:

- Problem: A dull blade requires more force to cut, which can crack or chip the tile.

- Solution: Regularly replace or sharpen your diamond blades to maintain optimal cutting performance.

- Product Suggestion: QEP 48 in. Manual Tile Cutter which is easy to maintain and suitable for various tile types.

Incorrect Blade Speed:

- Problem: Using the wrong speed can cause overheating and blade wear.

- Solution: Use a tile saw like the RIDGID 6.5 Amp Corded 7 in. Table Top Wet Tile Saw that allows speed adjustments according to the blade specifications.

Recommended Practices

- Read the Manufacturer’s Specifications: Always check the blade manufacturer’s recommendations for material compatibility.

- Test Cutting: Perform a test cut on a spare piece of tile to ensure the blade cuts smoothly without chipping.

- Proper Installation: Ensure the blade is installed correctly and securely on the tile saw or cutter to prevent wobbling or misalignment.

Improper Use of Wet Saw Blades

Using a wet saw is one of the most efficient methods for cutting tile, particularly when you require clean, precise cuts for materials like porcelain, ceramic, or stone. However, the improper use of wet saw blades can result in less than satisfactory outcomes, including rough edges, chipping, and even breakage of the tile. Understanding how to correctly use these blades is key to maximizing both the performance of your cutting tool and the quality of the finished product.

Understanding Wet Saw Blades

Blade Types and Uses

- Continuous Rim Blades: Ideal for cutting ceramic, glass tiles, and porcelain, providing a smooth and chip-free finish.

- Segmented Rim Blades: Best suited for cutting marble, granite, and other hard materials. These blades have gaps (segments) that assist in removing debris and keeping the blade cool.

- Turbo Rim Blades: Combine the qualities of both continuous and segmented rims, offering a smoother cut than segmented blades but with greater speed and cooling capabilities.

Key Factors to Consider

- Proper Installation: Ensure that the blade is correctly aligned and securely fastened to the wet saw. An improperly installed blade can wobble, leading to uneven cuts.

- Correct Blade for Material: Always select a blade that is appropriate for the tile material. For example, using a continuous rim blade from Avanti Pro 7 in. Diamond Blade PD070S ensures smooth cuts on porcelain tiles.

Common Mistakes

- Using a Dry Blade: Wet saw blades require water to prevent overheating. Using a dry blade or inadequate water flow can cause the blade to wear prematurely and increase the risk of chipping the tile.

- Forcing the Tile: Pushing the tile too fast against the blade can result in poor cuts and blade damage. Let the blade do the work at a consistent, steady pace.

Best Practices for Using Wet Saw Blades

- Regular Inspection and Maintenance: Before each use, check the blade for wear and ensure it is sharp and clean. Replace the blade with products like Sigma 2B3 25 inch Tile Cutter for consistent performance.

- Adequate Water Flow: Ensure your wet saw’s water system is functioning correctly to keep the blade cool and minimize dust.

- Feed Rate: Adjust the feed rate according to the thickness and hardness of the tile. Slower feeds are necessary for thicker or harder materials.

Tools and Resources

- High-Quality Wet Saws: Invest in reliable tools such as the DeWalt D24000R 10 in. Wet Tile Saw or RIDGID 6.5 Amp Corded 7 in. Table Top Wet Tile Saw for best results.

- Education and Training: Familiarize yourself with the equipment’s manual and safety guidelines. Training sessions or tutorials can significantly improve your technique and understanding of different materials and blades.

Diamond Tile Cutter Maintenance Tips

Maintaining a diamond tile cutter involves several practices that ensure prolonged blade life, optimal performance, and safety. By adhering to maintenance guidelines, cleaning procedures, and understanding when to replace blades, you can ensure your tile cutter continues to perform at its best.

How to Prolong the Life of Diamond Blades

- Use the Correct Blade for the Material: Matching the blade to the material it’s designed to cut can prevent undue wear and tear. For example, use blades like the Avanti Pro 7 in. Diamond Blade PD070S for cutting porcelain tiles to ensure it remains sharp and efficient.

- Ensure Proper Blade Installation: A blade that is not correctly installed may wobble or bind, leading to uneven wear and potential breakage. Ensure all fittings are tight and the blade is mounted correctly according to the manufacturer’s instructions.

- Maintain Adequate Water Flow: For wet cutting blades, ensure the water flow is consistent and sufficient to keep the blade cool and reduce dust. This not only protects the blade from overheating but also minimizes wear.

Cleaning and Storing Blades

- Cleaning After Use: After each use, clean the blade with water to remove any debris or tile residue that could harden and cause the blade to wear unevenly. Use a soft brush to gently scrub the blade.

- Dry Before Storing: Once cleaned, allow the blade to dry completely to prevent rust or corrosion. Store it in a dry and cool place, ideally hung up or placed in a case where it won’t be bumped or dropped.

- Regular Inspections: Regularly inspect the blade for signs of wear such as segments on the rim or visible damage. Cleaning the blade regularly allows you to inspect it more thoroughly.

When to Replace Your Tile Cutter Blade

- Visual Inspection: Check for visible signs of wear or damage such as uneven segments, missing pieces from the rim, or excessive dullness.

- Cutting Performance: If the blade begins to require more pressure to cut or produces rougher cuts than usual, it may be time to consider replacing it.

- Measure Blade Diameter: Over time, blades wear down. Measure the diameter of the blade regularly to ensure it is within the operational limits set by the manufacturer.

Table: Blade Inspection Checklist

| Checkpoint | Description | Action if Compromised |

|---|---|---|

| Segment Integrity | Ensure segments are intact and securely attached. | Replace blade if segments are loose or missing. |

| Sharpness | Blade should remain sharp without chipping. | Sharpen or replace if dull or chipped. |

| Diameter Measurement | Compare current diameter to original specifications. | Replace if significantly reduced. |

Tools and Resources for Maintenance

- Blade Cleaning Kits: Consider purchasing a blade cleaning kit designed for diamond blades to ensure proper maintenance.

- Professional Inspections: Occasionally, have your blades inspected by a professional, especially if you use them frequently for heavy-duty cutting tasks.

FAQ: Diamond Tile Cutter and Blade Use

Will a Diamond Blade Cut Tile?

Yes, a diamond blade is specifically designed to cut through hard materials such as tile, including ceramic, porcelain, and stone. For optimal results, choose a blade suited to the specific type of tile material, like the DeWalt DWC860W Wet/Dry Tile Saw, which is equipped with a diamond blade ideal for cutting through tough ceramics and stone.

How Long Does a Diamond Blade Last?

The lifespan of a diamond blade depends on several factors, including:

- Material Type: Harder materials wear down blades faster.

- Blade Quality: Higher quality blades tend to last longer.

- Usage Frequency: More frequent use leads to quicker wear.

- Cutting Technique: Proper cutting techniques can extend the life of a blade. On average, a diamond blade can last between 12 to 120 hours of cutting time, depending on these factors.

Is it Better to Cut Ceramic Tile Wet or Dry?

- Wet Cutting: Preferred for most ceramic and porcelain tiles as it keeps the blade cool and minimizes dust and debris. Machines like the Sigma Kera-Cut Extendable 8AE2 are designed for wet cutting.

- Dry Cutting: Suitable for quick, small jobs. Requires a blade designed for dry cutting to handle the heat generated.

What is the Best Thing to Cut Tiles With?

The best tool for cutting tiles depends on the type of tile and the nature of the job:

- Wet Tile Saws: Best for large projects requiring precise cuts, like the Rubi DC-250 Python Tile Saw.

- Manual Tile Cutters: Great for straight cuts in ceramic and porcelain tiles.

- Angle Grinders: Suitable for making irregular cuts or small cutouts.

Do You Need Water with a Diamond Blade?

Yes, for wet cutting. Water significantly extends the life of diamond blades by reducing heat and removing dust. However, some blades are designed for dry cutting, but these typically wear out faster than those used with water.

How to Stop Tile Chipping When Cutting with a Grinder?

- Use a High-Quality Diamond Blade: A blade specifically for tiles, like the Diablo 4-1/2 in. Diamond Turbo Masonry Cut Off, reduces chipping.

- Adjust the Blade Depth: Ensure the blade doesn’t cut too deeply into the tile.

- Apply Gentle Pressure: Allow the blade to do the work without force.

- Tape the Cut Line: Apply masking tape along the cut line to support the tile’s surface and reduce chipping.

How to Tell if a Tile Saw Blade is Dull?

- Decreased Performance: The blade requires more pressure to cut than usual.

- Poor Cut Quality: The cuts become uneven or chipped.

- Visible Wear: Physical signs of wear on the blade segments.

Can You Sharpen a Diamond Blade?

Technically, you cannot “sharpen” diamond blades like traditional blades. Instead, you can restore the blade’s cutting ability by running it through a dressing stone or abrasive material, which removes the glazed over diamond particles and exposes new, sharp diamonds.

How Do I Choose a Diamond Blade?

- Consider the Material: Select a blade designed for the specific material you plan to cut.

- Match the Blade to Your Saw: Ensure the blade fits your saw’s specifications in terms of size and power.

- Cutting Conditions: Choose wet or dry cutting blades based on your typical work conditions.

- Quality vs. Cost: Invest in a higher-quality blade for frequent use to ensure durability and precision.